Wiring

MV1864P

11

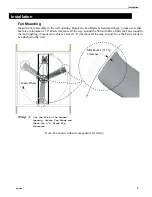

1. See Wiring diagram on Motor for Motor electrical connections. Follow local, state, and national electrical codes

for wiring

2. Install an electrical disconnect within reach of each Fan.

3. Route the motor cord (not supplied) toward the upper left corner of the Fan and attach the cord to the Motor Mount

using the Cable Tie—included in the hardware package. Leave a Drip Loop so that moisture collecting on the

Cord will not run down and damage the Motor

(See Figure 12)

. Cut out a section of the Screen where you want

the Cord to exit the Fan, so that the Screen can be removed without the Cord getting in the way

Figure 12)

. Use

the Nylon Cord Retainer and Lag Screw provided to secure the Cord to the Wall outside of the Fan.

(Figure 12)

Wiring

Figure 12. Wiring / Cord Routing

Drip Loop

Nylon Cord Retainer

and Lag Screw

Cut Screen to allow Cord exit

Use Nylon Tie to attach Cord to Post