20

Assembly Instructions

Remove all the separate parts from the packaging, lay them on the floor

and check roughly that all are there on the base of the assembly steps.

Please note that a number of parts are connected directly to the main

frame preassembled. In addition, there are several other individual parts

that have been attached to separate units. This will makes assembly

easier and quicker for you. Assembly time: 40 - 50 min.

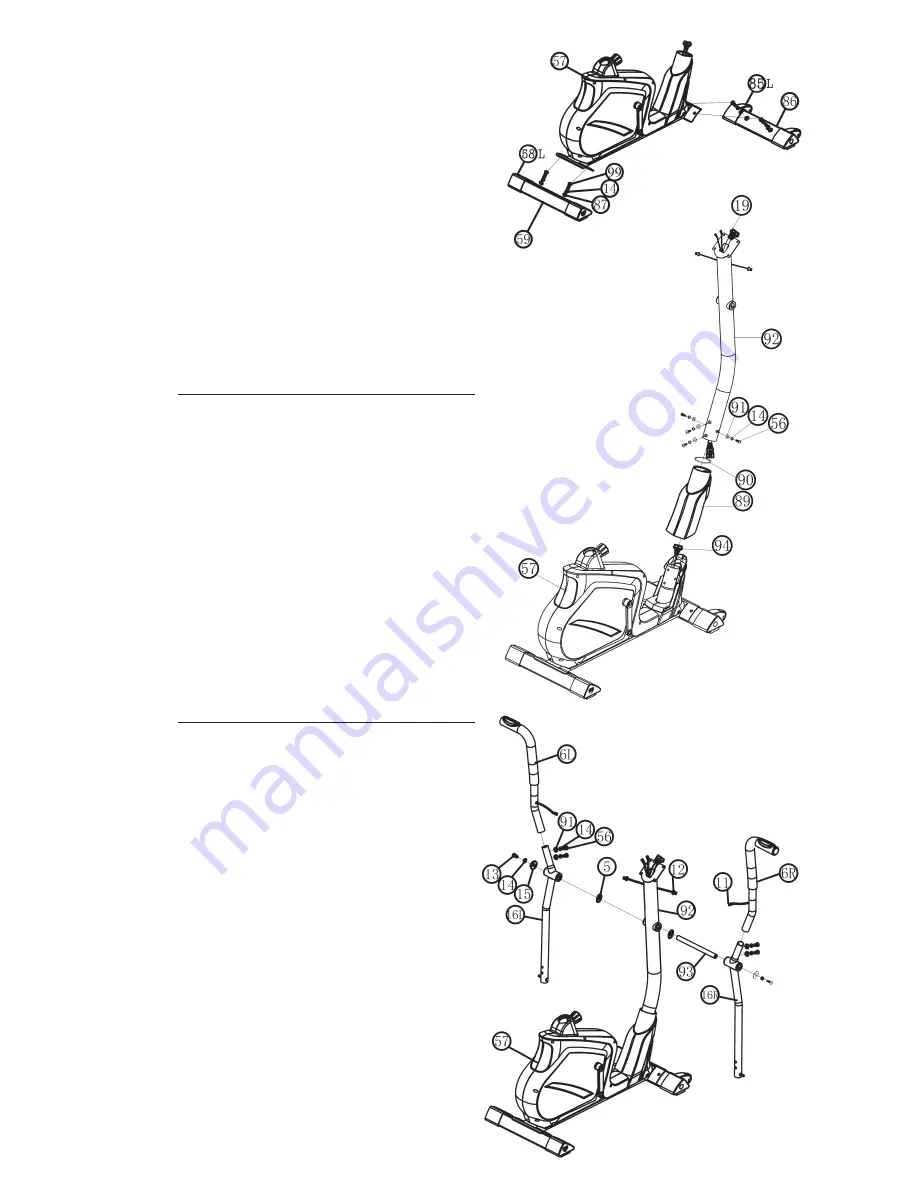

Step 1:

Attach the stabilizer (59+86) at main frame (57).

1. Attach the front foot (86) with preassembled transportation roller (85) to

the main frame (57). Do this with screws M8x25 (99), washers (87) and

spring washers (14).

2. Attach the rear foot (59) with preassembled height adjustable caps (58)

to the main frame (57). Do this with screws M8x25 (99), washers (87)

and spring washers (14). After assembly has been complete, you can

compensate for minor irregularities in the floor by turning the wheel at

foot caps (58). The equipment should be set up that the equipment does

not move of its own accord during a training session.

Step 2:

Connection of cables (19+94) and assembly of support (92) at the main

frame (57).

1. Place screws M8x20 (56), curved washers (91) and spring washers (14)

accessibly beside the front part of the main frame (57).

2. Place the lower end of the support (92) against the main frame (57) and

push the support cover (89) with rubber ring (90) onto the support (92).

Plug the ends of the two computer cable harnesses (19+94) projecting

from (57+92) together.

(Note: The computer cable harness (19) projecting from the support (92)

must not slide into the tube, as it is required for later steps of installa-

tion.) When joining the tubes, ensure that the cable connection will not

trapped.

3. Put one spring washer (14) and one curved washer (91) on each screw

(56). Push the screws (56) through the holes in the support (92), screw

into the threaded holes of the main frame (57) and tighten lightly. (This

screw connection point will screw firmly at least in Step 4.)

Step 3:

Installation of the handgrips (6) with connecting tubes (16) at support

(92).

1. Push the axle (93) into the middle position at handlebar support (92) and

put one wave washer (5) and the connecting tube right (16R) onto the

right axles’ end (93). Put on the screw M8x20 (13) a spring washer (14)

and a big washer 8//38 (15) and tighten it firmly. (Note: Right is specified

as viewed standing on the machine during training.)

2. Install the left connection tube (16L) incl. all additionally required parts

on the left hand side of the machine as described in 1.

3. Push the hand grips (6L+6R) onto the connecting tubes (16L+16R) and

adjust the holes in the tubes so that they are aligned.

(Note: the handgrip bars must be aligned after assembly so that the

upper ends are inclined outwards (away from the support (92)).

4. Push the bolt M8x20 (56) through the holes and tighten the handgrip

bars (6) with curved washers (91) and spring washers (14) at connection

tubes (16L+16R) firmly.

5. Connect the pulse connection cables (12) with pulse cables (11).