17

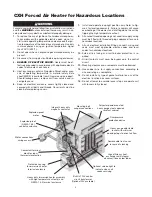

Renewal Parts Identification

Common Parts Shown in Figure 16

Item#

Description

Code CXHA-03,

05, 07 & 10

Part No.

CXH-A-15,

18 & 20

Part No.

CXH-A-25,

30 & 35

Part No.

1

Panel wrapper

207-303891-001 207-303891-002 207-303891-003

6

Panel Bottom

207-303881-001 207-303881-002 207-303881-003

8

Panel Front

207-303883-001 207-303883-002 207-303883-003

9

Louver

182-303884-001 182-303884-002 182-303884-003

10

Washer Shoulder

328-302074-002 328-302074-002 328-302074-002

12

Spring

276-130368-001 276-130368-001 276-130368-001

14

Terminal Box Cover 080-302079-001 080-302079-001 080-302079-001

15

Screw 10-32

248-073662-002 248-073662-002 248-073662-002

16

Fan Blade

Consult Factory Consult Factory Consult Factory

17

Fan Guard

134-302063-004 134-302063-005 134-302063-006

25

Enclosure

347-304561-001 347-304561-001 347-304561-001

26

Bolt 3/8-16, 1.5 lg

345-075603-263 345-075603-263 345-075603-263

27

Washer flat

328-075528-085 328-075528-085 328-075528-085

28

Washer lock

328-075571-011 328-075571-011 328-075571-011

29

Hex Nut 3/8-16

200-075473-044 200-075473-044 200-075473-044

30

Plug conduit 1/2”

221-302180-001 221-302180-001 221-302180-001

31

Plug conduit 1”

221-302180-003 221-302180-003 221-302180-003

32

Union conduit 3/4” 354-302165-001 354-302165-001 354-302165-001

33

Union conduit 3/4” 354-302243-001 354-302243-001 354-302243-001

34

Conduit Box

Consult factory 069-304115-002 069-304115-002

35

Conduit 3/4”

Consult factory

Consult factory

Consult factory

44

Plug conduit 3/4”

221-302180-002 221-302180-002 221-302180-002

50

Bolt 5/16-18

345-075603-218 345-075603-218 345-075603-218

51

Washer

328-075571-010 328-075571-010 328-075571-010

52

Nut 5/16-18

200-075473-039 200-075473-039 200-075473-039

62

Cover Exp. Proof

080-042350-007 080-042350-007 080-042350-007

75

Conduit 3/4”

069-115087-049 069-115087-079 069-115087-093

**Have motor manufacturer and model number availiable when ordering a

replacement motor (ATEX Certified).

***690V heaters - Contact factory for common parts

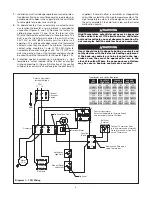

Motor & Heat Exchanger Parts

Model

Heat Exchanger* Item 49

CXH-C-03S-81

353-305234-001

CXH-C-03S-83

353-305234-001

CXH-C-03S-21

353-305234-002

CXH-C-03S-23

353-305234-002

CXH-C-03S-33

353-305234-003

CXH-C-03S-403

353-305234-004

CXH-C-03S-53

353-305234-005

CXH-C-03S-43

353-305234-008

CXH-C-03S-63

353-305234-009

CXH-C-05S-81

353-305234-011

CXH-C-05S-83

353-305234-011

CXH-C-05S-21

353-305234-012

CXH-C-05S-23

353-305234-012

CXH-C-05S-33

353-305234-013

CXH-C-05S-403

353-305234-014

CXH-C-05S-53

353-305234-015

CXH-C-05S-43

353-305234-018

CXH-C-05S-63

353-305234-019

CXH-C-07S-81

353-305235-001

CXH-C-07S-83

353-305235-001

CXH-C-07S-21

353-305235-002

CXH-C-07S-23

353-305235-002

CXH-C-07S-33

353-305235-003

CXH-C-07S-403

353-305235-004

CXH-C-07S-53

353-305235-005

CXH-C-07S-43

353-305235-008

CXH-C-07S-63

353-305235-009

CXH-C-10S-83

353-305235-011

CXH-C-10S-21

353-305235-012

CXH-C-10S-23

353-305235-012

CXH-C-10S-43

353-305235-015

CXH-C-10S-63

353-305235-016

CXH-C-10M-33

353-305236-002

CXH-C-10M-403

353-305236-003

CXH-C-10M-53

353-305236-004

CXH-C-15M-83

353-305236-005

CXH-C-15M-23

353-305236-006

CXH-C-15M-33

353-305236-007

CXH-C-15M-403

353-305236-008

CXH-C-15M-53

353-305236-009

CXH-C-15M-43

353-305236-012

CXH-C-15M-63

353-305236-013

CXH-C-20M-33

353-305236-017

CXH-C-20M-403

353-305236-018

CXH-C-20M-53

353-305236-019

CXH-C-20M-43

353-305236-022

CXH-C-20M-63

353-305236-023

CXH-C-25L-33

353-305237-001

CXH-C-25L-403

353-305237-002

CXH-C-25L-53

353-305237-003

CXH-C-25L-43

353-305237-006

CXH-C-25L-63

353-305237-007

CXH-C-30L-33

353-305237-009

CXH-C-30L-403

353-305237-010

CXH-C-30L-53

353-305237-011

CXH-C-30L-43

353-305237-014

CXH-C-30L-63

353-305237-015

CXH-C-35L-43

353-305237-020

CXH-C-35L-63

353-305237-021

* For arctic duty conditions, heat exchanger with

ethylene glycol are required. Consult factory.

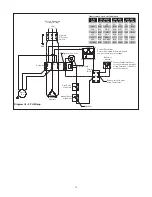

Optional Equipment

Optional Equipment Parts

Description

Part Number

Pilot Light (Amber)

213-121103-025

Pilot Light (Red)

213-121103-026

Insulation Fault Relay

072-305296-001

Mounting Kit Adapter

CXH-A-03S through 10S

027-302361-001

CXH-A-15M through 20M

027-302361-002

CXH-A-25L through 35L

027-302361-003

The factory must perform the replacement of the

immersion heater or high temperature cutout. The

heat exchanger seal must not be broken. Consult

factory for service.