2

Table of Contents

Section Page

1. Warnings .............................................................................................................................. 3

2. Optional Equipment ............................................................................................................. 4

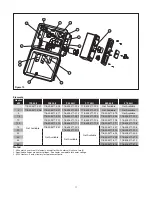

3. Package Contents ................................................................................................................ 4

4. Mounting Instructions .......................................................................................................... 5

5. Standard “L” Bracket Installation ......................................................................................... 6

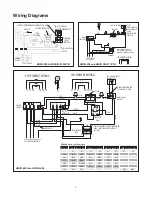

6. Wiring ................................................................................................................................... 7

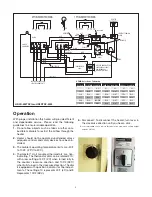

7. Operation.............................................................................................................................. 9

8. Maintenance ....................................................................................................................... 10