9

REMOTE FAN SWITCH

480V + Heaters require an additional fan relay. (Avail-

able as a kit or factory installed option and standard on

heaters 20kW and above).

The wall switch is packed in the wiring compartment.

1. Use 18 gauge (min.) NEC Class 1, 600V wiring that

meets all Local and NEC requirements.

2. Install the wall switch in a standard wall box in any

convenient location that is protected from traffic or

other accidental damage.

3. Connect the field wire to the switch lead wires with

suitable connectors.

OPTIONAL THERMOSTAT (HVH-TK) Refer to In-

struction Sheet PF204.

Heaters can be equipped with an optional thermostat

of the Bulb and Capillary type for automatic tempera-

ture control (Figure 8). The thermostat controls the

heating elements and fan simultaneously to achieve

set temperature.

The “Lo” setting of the thermostat is approximately

40˚F, and the “Hi” setting is approximately 90˚F.

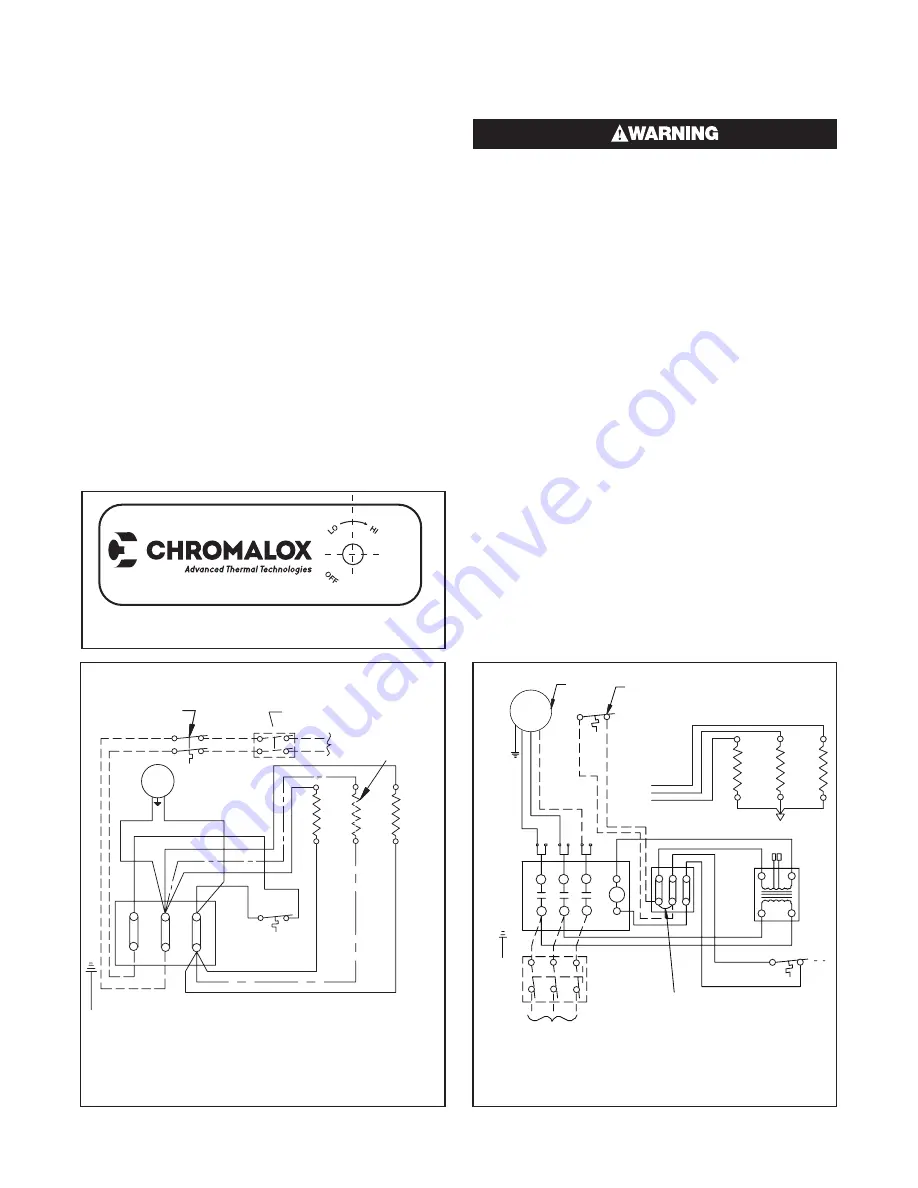

Figure 9 — Thermostat Location, Front View

CONTROL VOLTAGE WIRING — EXTERNAL RE-

MOTE THERMOSTATS AND FAN SWITCHES

ELECTRIC SHOCK HAZARD. Be sure electricity

is turned off at main switch first before wiring.

Any installation involving electric heaters must

be effectively grounded in accordance with the

National Electrical Code to eliminate shock

hazard.

1. Use 600 volt, NEC Class 1 insulated wiring with a

minimum gage of 18 for thermostats and minimum

gauge of 14 for line voltage motor switch (remote

fan switch without relay).

2. The thermostat should be located in the area to be

heated on an inside wall. The thermostat should

not be exposed to drafts, sunlight, radiation from

hot objects, or in a direct line with the discharge

from the unit heater.

3. Install the thermostat approximately 5 feet above

the floor line.

4. Install the remote fan switch in any convenient lo-

cation that is protected from traffic or likely acci-

dental damage.

5. Internal optional controls are shown on the unit

heater wiring diagrams by a dash line.

T1

T2

T3

L1

L2

L3

Terminal

Block

Cutout

Elements

1Ø Element wiring

(Omit for 2 element

heaters)

Optional disconnect switch

built-in or field installed

Power

60 Hz

Optional thermostat

built-in or field

installed

Blue

Blue

Motor

Cutout

NOTES:

1. Omit "L3" wiring for 1ø heaters

2. 3ø Motors used on all 480V, 7.5KV or higher

Remove jumper wire when

thermostat is used

Black

Red

Power 60 Hz

Pink

Optional

Disconnect

switch

built-in

or field

installed

T1

T2

T3

L1

L2

L3

Yellow

Blue

Sec

C1

C2

C3

3Ø Wiring

See Note #2

Optional Thermostat

Built-in or Field Installed

Motor

TO T1

TO T2

TO T3

Figure 10

Figure 11

Summary of Contents for HVH Series

Page 2: ...2 ...