FIRE HAZARD. An integral thermostat, if provided,

is designed for temperature control service only.

Because the thermostat does not fail safe, it should

not be used for temperature limiting duty. Wiring to

this device is the responsibility of the user.

The system designer is responsible for the safety

of this equipment and should install adequate

back-up controls and safety devices with their

electric heating equipment. Where the conse-

quences of failure could result in personal injury or

property damage, back-up controls are essential.

FIRE/EXPLOSION HAZARD.

Use only Explosion

Resistant Enclosures (E2, E3 or ER) in hazardous

atmospheres where flammable vapors, gases, liquids

or other combustible atmospheres are present as

defined in the National Electrical Code (NFPA 70).

Failure to comply could result in personal injury or

property damage.

ELECTRIC SHOCK HAZARD. Disconnect all power

before installing or servicing heater. Failure to do

so could result in personal injury or property dam-

age. Heater must be installed by a qualified person

in accordance with the National Electrical Code,

NFPA 70.

1.

Before installing, check your Over-The-Side heater for any dam-

age that may have occurred during shipment. Also, check to ensure

that the line voltage is the same as that stamped on the nameplate.

2.

Do not bend heating elements. If bending is necessary, consult factory.

3. IMPORTANT:

Mount the heater in the tank so that the liquid

level will always be above the effective heated portion of the

heater. If the heater is not properly submerged, it will overheat and

damage the heating elements and create a possible fire hazard due

to excessive sheath temperatures. See “Warning” under

“Installation” section. (see Figure 3).

4.

Heater must be supported from tank bottom. Heater must not be

operated in sludge. Sludge legs can be provided. Assemble as

shown in Figure 3.

5.

Where work will pass over or near equipment, additional protec-

tion, such as a metal guard, may be needed.

6.

In the electroplating operation the heaters are not, under any cir-

cumstance, to be placed between the electrodes and the work.

7.

When melting solids by direct immersion, a surface vent should be

provided to allow gases to escape. Operate the heater on half volt-

age until melted material completely covers the heater area.

8.

A drip loop is recommended to minimize passage of moisture

along wiring into terminal enclosure and connections.

FIRE HAZARD. Since heaters are capable of developing

high temperatures, extreme care should be taken to:

A.

Use explosion-resistant terminal enclosures in hazardous loca-

tions. Consult Chromalox for selection of explosion-resistant

terminal enclosures for hazardous locations.

B.

Avoid contact between heater and combustible materials.

C.

Keep combustible materials far enough away to be free of the

effects of high temperatures.

FREEZE HAZARD. Some Over-The-Side heaters are

equipped with a thermowell for process control or

over-temperature control. Do not allow moisture to

accumulate in thermowell. Freezing temperatures

can cause damage that may result in the heated

medium leaking into terminal enclosure.

INSTALLATION

4

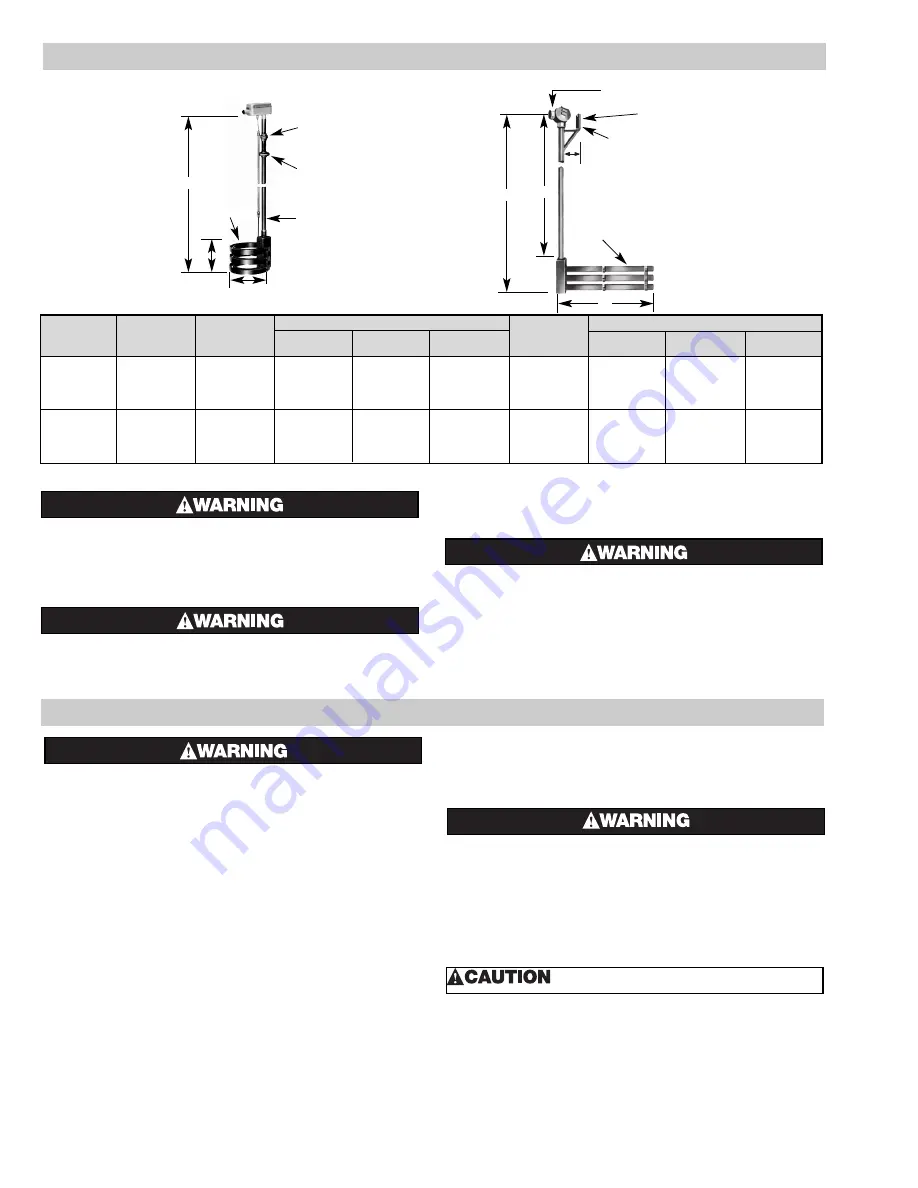

Specifications –

Kilowats

Dimensions (In.)

No.

Regular Oil

Fuel Oil

(A)

(B) Min. Tank

Model

Blades

Phase

18 W/in

2

12 W/in

2

40 W/in

2

Voltage

Riser Height Opening Clearance

(C)

BLCK-MH618

6

1 or 3

⌬

12

7.5

–

240 or 480

144

16-1/2

8-7/8

BLCK-MH824

8

1 or 3

⌬

16

10

–

240 or 480

144

16-1/2

12

BLCK-MH103

10

1 or 3

⌬

20

12.5

–

240 or 480

144

16-1/2

15-1/8

BLCK-MH236

12

1 or 3

⌬

24

15

–

240 or 480

144

16-1/2

18-1/4

BLCS-618

6

1 or 3

⌬

12

7.5

–

240 or 480

144

34

8-7/8

BLCS-824

8

1 or 3

⌬

16

10

–

240 or 480

144

34

12

BLCS-1030

10

1 or 3

⌬

20

12.5

–

240 or 480

144

34

15-1/8

BLCS-1236

12

1 or 3

⌬

24

15

–

240 or 480

144

34

18-1/4

BLCK, BLCS

4 to 12 Blades

Type BLCK-MH

1-1/4” Ground Joint

Malleable Iron Union

1-1/4” Round

Floor Flange

Malleable Iron

1-1/4” Steel

Pipe Riser

Type BLCS

1-1/4” Pipe Opening

(4-5/32)

of Mtg. Hole

same as Dim. “A”

Suspension Bracket

4 to 12 Blades

CL

(C)

(B)

(A)

(A)

(C)

(B)

!

SPECIFICATIONS (cont’d.)