29

SET POINTS

This instrument allows to use 2 set points: SP and

SP2.

The set point selection is possible only by logic

input.

Set point transfer

:

The transfer between one set point to another (or

between two different set point values) may be

realized by a step transfer or by a ramp with two

different programmable rate of change (ramp up

and ramp down).

Slope value

: 1 - 100 eng. unit/min or step.

Set points limiter

: RLO and RHI parameters, pro-

grammable.

CONTROL ACTIONS

Control action

: PID + SMART

Type

: One (heating or cooling) or two (heating and

cooling) control outputs.

Proportional Band

(Pb):

Range: - from 1.0 to 100.0 % of the input span for

process with one control output.

- from 1.5 to 100.0 % of the input span for

process with two control outputs.

When Pb=0, the control action becomes ON/OFF.

Hysteresis

(for ON/OFF control action):

from 0.1% to 10.0% of the input span.

Integral time (Ti)

: from 1s to 20 min. or excluded.

Derivative time (Td)

: from 1 s to 10 min.

If zero value is selected, the derivative action is

excluded.

Integral pre-load

:

- from 0.0 to 100.0 % for one control output

- from -100.0 (cooling) to +100.0 % (heating) for

two control outputs.

SMART

: keyboard enabling/disabling

Auto/Manual

: selectable by front pushbutton.

Auto/Manual transfer

: bumpless method type

Indicator "MAN"

: OFF in auto mode and lit in

manual mode.

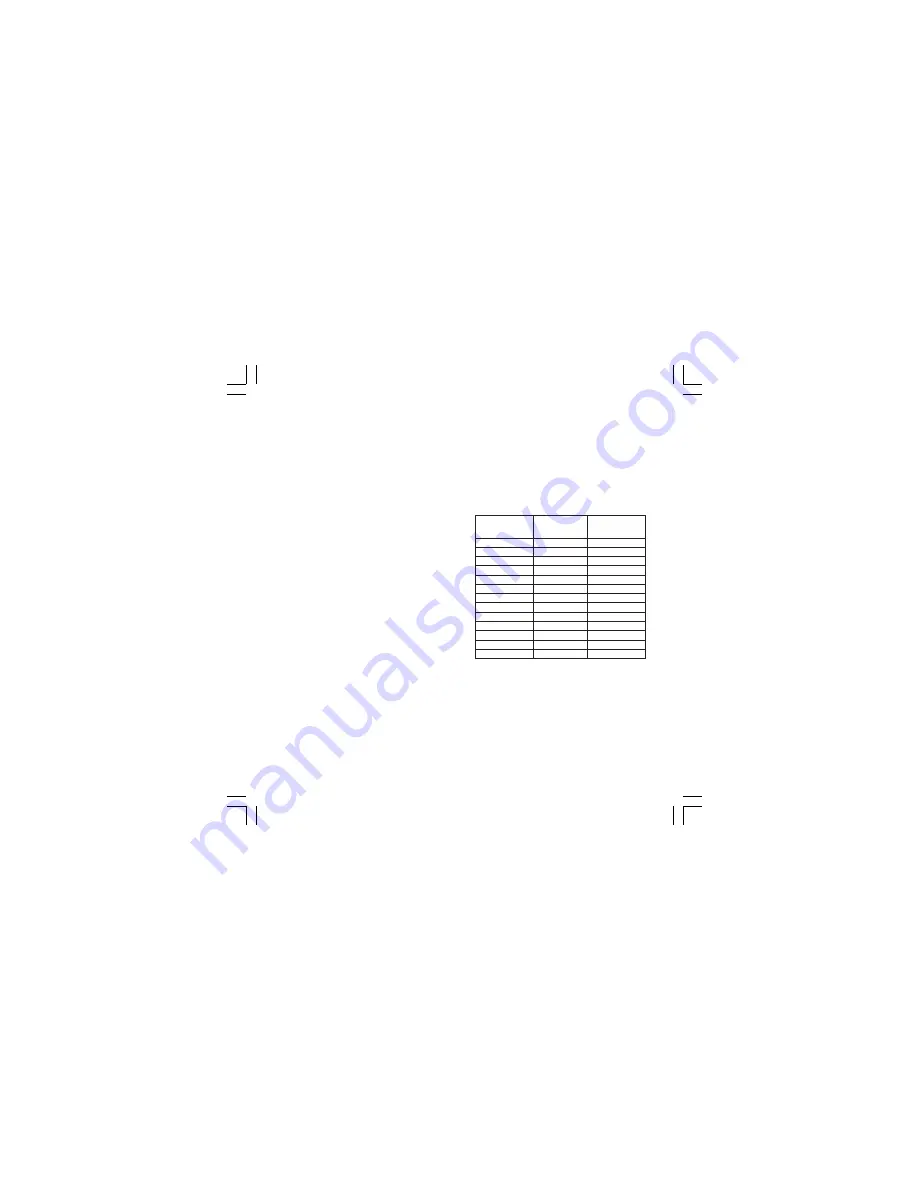

OUTPUTS

Type

: This instrument is equipped with 3

independent outputs programmable as follows:

Out 1

Out 2

Out 3

linear (mA)

relay

relay

Heating

AL1

AL2

Heating

Cooling

AL2

Heating

AL1

Cooling

Cooling

AL1

AL2

Cooling

Heating

AL2

Cooling

AL1

Heating

Retransm.

Heating

AL2

Retransm.

AL1

Heating

Retransm.

Cooling

AL2

Retransm.

AL1

Cooling

Retransm.

Heating

Cooling

Retransm.

Cooling

Heating

Retransm.

AL1

AL2

Control output updating time

:

- 250 ms when a linear input is selected

- 500 ms when a TC or RTD input is selected.

Action

: direct/reverse programmable by front

keyboard.

Output level indication:

The instrument displays separately the output 1

level (heating) and the output 2 level (cooling).

Output status indication

: the OUT 1 LED will

flash with a duty cycle proportional to the output 1

power. Two indicators (OUT 2 and/or OUT 3) are

lit when the respective output is in ON condition.

1604-7-1-AB.p65

5/16/00, 10:50 AM

29