DESCRIPTION . . . . . . . . . . . SPECIFICATIONS

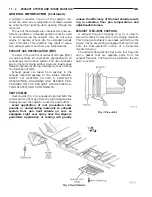

Valve Face Angle

Intake . . . . . . . . . . . . . . . . . . . . . . . 55°30’– 55°50’

Exhaust . . . . . . . . . . . . . . . . . . . . . 45°25’– 45°35’

Valve Head Diameter

Intake . . . . . . . . . . . . . . . . . . . . . 40.05–40.25 mm

Exhaust . . . . . . . . . . . . . . . . . . . . . 33.8–34.0 mm

Valve Head Stand Down

Intake . . . . . . . . . . . . . . . . . . . . . . . 1.08–1.34 mm

Exhaust . . . . . . . . . . . . . . . . . . . . . 1.99–1.25 mm

Valve Stem Diameter

Intake . . . . . . . . . . . . . . . . . . . . . 7.940–7.960 mm

Exhaust . . . . . . . . . . . . . . . . . . . . 7.922–7.940 mm

Valve Clearance in Guide

Intake . . . . . . . . . . . . . . . . . . . . . 0.040–0.075 mm

Exhaust . . . . . . . . . . . . . . . . . . . . 0.060–0.093 mm

Valve Guide

Inside Diameter . . . . . . . . . . . . . . . 8.0–8.015 mm

Fitted Height . . . . . . . . . . . . . . . . . 13.5–14.0 mm

Valve Spring

Free Length . . . . . . . . . . . . . . . . . . . . . 44.65 mm

Fitted Length . . . . . . . . . . . . . . . . . . . . . 38.6 mm

Load at Fitted Length . . . . . . . . . . . . 34

6

6% Kg

Load at Top of Lift . . . . . . . . . . . . . 92.5

6

4% Kg

Number of Coils . . . . . . . . . . . . 5.33 Valve Timing

Oil Pressure

at 4000 rpm . . . . . 3.0 to 4.5 bar (Oil at 90–100°C)

Pressure Relief Valve Opens . . . . . . . . . . 6.38 bar

Pressure Relief Valve–Free Length . . . . . 57.5 mm

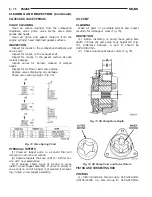

Oil Pump

Outer Rotor End Float . . . . . . . . . . 0.03–0.09 mm

Inner Rotor End Float . . . . . . . . . . 0.03–0.09 mm

Outer Rotor to Body Diameter

Clearance . . . . . . . . . . . . . . . . . . 0.130–0.230 mm

Rotor Body to Drive Gear Clearance (Pump Not

Fitted) . . . . . . . . . . . . . . . . . . . . . . 3.27–3.73 mm

TORQUE

DESCRIPTION . . . . . . . . . . . . . . . . . . . TORQUE

Generator Mounting Bracket

Bolts . . . . . . . . . . . . . . . . . . . . 47 N·m (35 ft. lbs.)

Camshaft Thrust Plate Retaining Bolts

Bolt . . . . . . . . . . . . . . . . . . . . . 24 N·m (18 ft. lbs.)

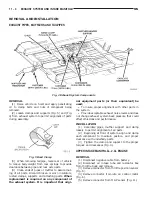

Cylinder Head

Bolts . . See Cylinder Head Installation Procedure

Connecting Rod

Bolts . . . . . . . . . . . 29.5 N·m +60° (22 ft. lbs. +60°)

Crankshaft Bearing Carrier

Bolts . . . . . . . . . . . . . . . . . . . . 44 N·m (32 ft. lbs.)

Crankshaft damper (Pulley)

Nut . . . . . . . . . . . . . . . . . . . 441 N·m (325 ft. lbs.)

EGR Valve to Intake Manifold

Tube . . . . . . . . . . . . . . . . . . . . 26 N·m (19 ft. lbs.)

DESCRIPTION . . . . . . . . . . . . . . . . . . . TORQUE

EGR Tube to EGR Valve

Bolts . . . . . . . . . . . . . . . . . . . . 26 N·m (19 ft. lbs.)

Engine Mount—Front

Support Bracket Engine Bolts . 68 N·m (50 ft. lbs.)

Support Bracket Transmission

Bolts . . . . . . . . . . . . . . . . . . . 101 N·m (75 ft. lbs.)

Support Cushion Crossmember

Bolts . . . . . . . . . . . . . . . . . . . . 54 N·m (40 ft. lbs.)

Support Cushion Thru Bolt . . . 65 N·m (48 ft. lbs.)

Engine Mount—Rear

Support Bracket Transmission

Bolts . . . . . . . . . . . . . . . . . . . 101 N·m (75 ft. lbs.)

Support Bracket to Engine

Bracket . . . . . . . . . . . . . . . . . 101 N·m (75 ft. lbs.)

Support Cushion Thru Bolt . . . 68 N·m (50 ft. lbs.)

Engine Mount—Left

Transmission Mounting Bolts . 54 N·m (40 ft. lbs.)

Support Cushion Thru Bolt . . . 71 N·m (53 ft. lbs.)

Engine Mount—Right

Mount to Frame Rail Bolts . . . 68 N·m (50 ft. lbs.)

Mount Bolt (Horizontal) . . . 145 N·m (107 ft. lbs.)

Mount Bolt (Vertical) . . . . . . . 101 N·m (75 ft. lbs.)

Right Engine Mount Bracket

Bolts . . . . . . . . . . . . . . . . . . . . 40 N·m (30 ft. lbs.)

Exhaust Pipe to Turbocharger

Bolts . . . . . . . . . . . . . . . . . . . 28 N·m (250 in. lbs.)

Exhaust Manifold Outlet to Turbo

Nuts . . . . . . . . . . . . . . . . . . . . 32 N·m (24 ft. lbs.)

Exhaust Elbow to Turbo

Bolts . . . . . . . . . . . . . . . . . . . . 30 N·m (22 ft. lbs.)

Exhaust Manifold Mounting

Nuts . . . . . . . . . . . . . . . . . . . . 30 N·m (22 ft. lbs.)

Flywheel

Bolts . . . . . See Rear Crankshaft Seal Installation

Procedure

Engine Adaptor Plate

Bolts . . . . . . . . . . . . . . . . . . . . 47 N·m (35 ft. lbs.)

Front Timing Gear Cover

Bolts . . . . . . . . . . . . . . . . . . . . 11 N·m (96 in. lbs.)

Fuel Filter

Nuts . . . . . . . . . . . . . . . . . . . 28 N·m (250 in. lbs.)

Glow Plugs

Plugs . . . . . . . . . . . . . . . . . . 14 N·m (120 in. lbs.)

Idler Pulley Pump Support Bracket

Nuts . . . . . . . . . . . . . . . . . . . 26 N·m (228 in. lbs.)

Idler Pulleys (left handed threads)

Bolts . . . . . . . . . . . . . . . . . . . . 47 N·m (35 ft. lbs.)

Injector Pump fuel lines

Nuts . . . . . . . . . . . . . . . . . . 17.6 N·m (156 in. lbs.)

Injector Pump Gear

Lock Nut . . . . . . . . . . . . . . . . . . . . . . . . . . 86 N·m

Injector Pump Mounting

Nuts . . . . . . . . . . . . . . . . . . 27.5 N·m (240 in. lbs.)

9 - 80

ENGINE

NS/GS

SPECIFICATIONS (Continued)

Summary of Contents for 1998 Voyager

Page 8: ...FASTENER IDENTIFICATION NS INTRODUCTION 5 GENERAL INFORMATION Continued ...

Page 9: ...FASTENER STRENGTH 6 INTRODUCTION NS GENERAL INFORMATION Continued ...

Page 11: ...METRIC CONVERSION 8 INTRODUCTION NS GENERAL INFORMATION Continued ...

Page 12: ...TORQUE SPECIFICATIONS NS INTRODUCTION 9 GENERAL INFORMATION Continued ...

Page 16: ......

Page 26: ......

Page 93: ...RED BRAKE WARNING LAMP FUNCTION NS BRAKES 5 11 DIAGNOSIS AND TESTING Continued ...

Page 94: ...POWER BRAKE SYSTEM DIAGNOSTICS 5 12 BRAKES NS DIAGNOSIS AND TESTING Continued ...

Page 95: ...VEHICLE ROAD TEST BRAKE NOISE NS BRAKES 5 13 DIAGNOSIS AND TESTING Continued ...

Page 222: ...COOLING SYSTEM DIAGNOSIS 7 8 COOLING SYSTEM NS DIAGNOSIS AND TESTING Continued ...

Page 223: ...NS COOLING SYSTEM 7 9 DIAGNOSIS AND TESTING Continued ...

Page 224: ...7 10 COOLING SYSTEM NS DIAGNOSIS AND TESTING Continued ...

Page 225: ...NS COOLING SYSTEM 7 11 DIAGNOSIS AND TESTING Continued ...

Page 226: ...7 12 COOLING SYSTEM NS DIAGNOSIS AND TESTING Continued ...

Page 280: ......

Page 286: ......

Page 289: ...CHARGING SYSTEM SCHEMATIC TYPICAL NS CHARGING SYSTEM 8C 3 DIAGNOSIS AND TESTING Continued ...

Page 291: ...CHARGING SYSTEM TEST NS CHARGING SYSTEM 8C 5 DIAGNOSIS AND TESTING Continued ...

Page 292: ...OVERCHARGE TEST 8C 6 CHARGING SYSTEM NS DIAGNOSIS AND TESTING Continued ...

Page 294: ...VOLTAGE DROP TEST 8C 8 CHARGING SYSTEM NS ...

Page 298: ......

Page 372: ......

Page 377: ...NS GS INSTRUMENT PANEL AND SYSTEMS 8E 5 DIAGNOSIS AND TESTING Continued ...

Page 378: ...8E 6 INSTRUMENT PANEL AND SYSTEMS NS GS DIAGNOSIS AND TESTING Continued ...

Page 379: ...NS GS INSTRUMENT PANEL AND SYSTEMS 8E 7 DIAGNOSIS AND TESTING Continued ...

Page 380: ...8E 8 INSTRUMENT PANEL AND SYSTEMS NS GS DIAGNOSIS AND TESTING Continued ...

Page 381: ...NS GS INSTRUMENT PANEL AND SYSTEMS 8E 9 DIAGNOSIS AND TESTING Continued ...

Page 382: ...8E 10 INSTRUMENT PANEL AND SYSTEMS NS GS DIAGNOSIS AND TESTING Continued ...

Page 383: ...NS GS INSTRUMENT PANEL AND SYSTEMS 8E 11 DIAGNOSIS AND TESTING Continued ...

Page 384: ...8E 12 INSTRUMENT PANEL AND SYSTEMS NS GS DIAGNOSIS AND TESTING Continued ...

Page 385: ...NS GS INSTRUMENT PANEL AND SYSTEMS 8E 13 DIAGNOSIS AND TESTING Continued ...

Page 386: ...8E 14 INSTRUMENT PANEL AND SYSTEMS NS GS DIAGNOSIS AND TESTING Continued ...

Page 402: ......

Page 428: ......

Page 440: ......

Page 478: ......

Page 496: ......

Page 504: ......

Page 508: ......

Page 524: ......

Page 542: ......

Page 546: ......

Page 550: ......

Page 559: ...SPECIAL TOOLS SPECIAL TOOL Degausser 6029 NS OVERHEAD CONSOLE 8V 9 ...

Page 560: ......

Page 562: ......

Page 564: ...8W 01 2 8W 01 GENERAL INFORMATION NS GS DESCRIPTION AND OPERATION Continued ...

Page 565: ...NS GS 8W 01 GENERAL INFORMATION 8W 01 3 DESCRIPTION AND OPERATION Continued ...

Page 580: ......

Page 616: ......

Page 660: ......

Page 664: ......

Page 704: ......

Page 718: ......

Page 728: ......

Page 740: ......

Page 744: ......

Page 758: ......

Page 768: ......

Page 784: ......

Page 792: ......

Page 796: ......

Page 800: ......

Page 814: ......

Page 822: ......

Page 826: ......

Page 832: ......

Page 836: ......

Page 840: ......

Page 876: ......

Page 1024: ......

Page 1220: ...Fig 3 Lubrication Lines 9 42 ENGINE NS GS DESCRIPTION AND OPERATION Continued ...

Page 1224: ...ENGINE DIAGNOSIS MECHANICAL CONT 9 46 ENGINE NS GS DIAGNOSIS AND TESTING Continued ...

Page 1286: ...Fig 5 Front Crossmember Dimensions 13 6 FRAME AND BUMPERS NS SPECIFICATIONS Continued ...

Page 1287: ...Fig 6 Engine Compartment Top View NS FRAME AND BUMPERS 13 7 SPECIFICATIONS Continued ...

Page 1289: ...Fig 8 Full Vehicle Bottom View NS FRAME AND BUMPERS 13 9 SPECIFICATIONS Continued ...

Page 1291: ...Fig 11 Body Side Openings NS FRAME AND BUMPERS 13 11 SPECIFICATIONS Continued ...

Page 1292: ......

Page 1302: ...FUEL PRESSURE BELOW SPECIFICATIONS 14 8 FUEL SYSTEM NS DIAGNOSIS AND TESTING Continued ...

Page 1304: ...FUEL INJECTOR DIAGNOSIS 14 10 FUEL SYSTEM NS DIAGNOSIS AND TESTING Continued ...

Page 1368: ......

Page 1426: ......

Page 1472: ......

Page 1479: ...Diagnosis Guide NS TRANSAXLE AND POWER TRANSFER UNIT 21 5 DIAGNOSIS AND TESTING Continued ...

Page 1480: ...Diagnosis Guide 21 6 TRANSAXLE AND POWER TRANSFER UNIT NS DIAGNOSIS AND TESTING Continued ...

Page 1481: ...Diagnosis Guide NS TRANSAXLE AND POWER TRANSFER UNIT 21 7 DIAGNOSIS AND TESTING Continued ...

Page 1482: ...Diagnosis Guide 21 8 TRANSAXLE AND POWER TRANSFER UNIT NS DIAGNOSIS AND TESTING Continued ...

Page 1483: ...Diagnosis Guide NS TRANSAXLE AND POWER TRANSFER UNIT 21 9 DIAGNOSIS AND TESTING Continued ...

Page 1484: ...Diagnosis Guide 21 10 TRANSAXLE AND POWER TRANSFER UNIT NS DIAGNOSIS AND TESTING Continued ...

Page 1485: ...Diagnosis Guide NS TRANSAXLE AND POWER TRANSFER UNIT 21 11 DIAGNOSIS AND TESTING Continued ...

Page 1486: ...Diagnosis Guide 21 12 TRANSAXLE AND POWER TRANSFER UNIT NS DIAGNOSIS AND TESTING Continued ...

Page 1656: ......

Page 1723: ...LEAD CORRECTION CHART NS TIRES AND WHEELS 22 5 DIAGNOSIS AND TESTING Continued ...

Page 1726: ...SPECIFICATIONS TIRE SPECIFICATIONS 22 8 TIRES AND WHEELS NS ...

Page 1866: ......

Page 1904: ......

Page 1928: ......