Summary of Contents for Conquest 1988

Page 7: ...INTRODUCTION Vehicle Identification 7 LOCATIONS ransmlsston OOLO634 OOL0637 ...

Page 27: ...ELECTRICAL SYSTEM PARTS LOCATION Grounding i I 36Y51 ...

Page 45: ...WIRING HARNESS Wiring Harness Overview 8 31 Wiring Harness Overview NOBDC ...

Page 49: ...WIRING HARNESS Engine Compartment 8 35 A 68 A 73 A 78 I A 84 36Y 56 ...

Page 67: ...WIRING HARNESS ECI System Circuit 8 55 ECl6cz j EC1691 ...

Page 68: ...8 56 WIRING HARNESS ECI System Circuit A r condlttoner switch I Boost meter ...

Page 69: ...WIRING HARNESS ECI System Circuit 8 57 ...

Page 104: ...gg WIRING HARNESS Rear Brake Lock up Control Circuit ar TRANSMISSION LUGGAGE COMPARTMENT ...

Page 108: ...8 96 i WIRING HARNESS Speed Control System Circuit LUGGAGE COMPARTMENT El ...

Page 245: ...ACCESSORY Clock 8 233 CLOCK NOBMUAC REMOVAL AND INSTALLATION Clock _ ...

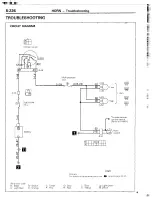

Page 346: ...31 Horn Relay Power supply Circuit To battery fuse A a f3 From harness side Horn relay ...

Page 350: ......