the oil pump case and the rear is retained in a die-

cast aluminum block-mounted housing.

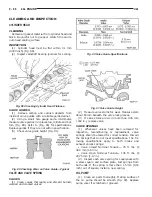

PISTONS

Are aluminum alloy with cast in steel struts at the

pin bosses for autothermic control. The piston head is

designed with valve recesses to provide for valve

clearance. The piston rings consist of a chrome-

plated, barrel faced design for the top ring, the sec-

ond ring is a cast iron tapered face design and the oil

ring is a chrome faced three piece design. Piston pins

are press-fitted into place, to join the pistons to the

forged steel connecting rods. The large end of the

connecting rod has a oil jet hole for lubrication of the

thrust side of the cylinder.

CYLINDER HEAD

The aluminum alloy cylinder heads feature a pent-

roof design with four valves per cylinder. Valve

guides are made of cast iron alloy and seat inserts

are made of sintered alloy iron, these are pressed

into the head. To improve combustion efficiency the

chambers have a compact pent-roof design with a

squish area. The cylinder heads are common to

either cylinder bank.

CAMSHAFTS

Two overhead camshafts provide valve actuation,

one left (radiator side of cylinder bank) and one

right. The distributor is directly driven by the right

camshaft. Both camshafts are supported by four

bearing journals intregal with the head. A flange at

the rear of the camshaft acts as a thrust collar. Right

and Left camshaft driving sprockets are interchange-

able. The sprockets and the engine water pump are

driven by the timing belt.

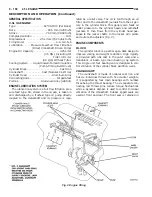

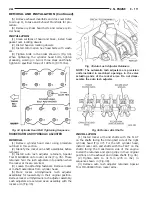

ROCKER ARM SHAFTS

The shafts are retained by retaining caps and

bolts. Four shafts are used, one for each intake and

exhaust rocker arm assembly on each cylinder head.

The hollow shafts provide a duct for lubricating oil

flow from the cylinder head to the valve mechanisms.

Rocker shaft springs are use on the intake shafts

ONLY to obtain the proper clearance between the

intake rocker arms and the spark plug tubes.

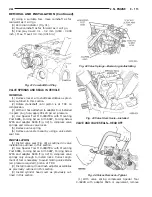

ROCKER ARMS

Are of light weight die-cast with roller type fol-

lower operating against the camshaft. The valve

actuating end of the rocker arms are machined for

hydraulic lash adjusters, eliminating the need for

periodic valve lash adjustment.

VALVES

Four valves per cylinder are actuated by die-cast

aluminum roller rocker arms and hydraulic lash

adjusters assemblies which pivot on rocker arm

shafts. All valves have 6 mm diameter chrome plated

valve stems. The valve train has 33 mm (1.299 inch)

diameter intake valves and 29 mm (1.141 inch) diam-

eter exhaust valves. The valves have a carbo-nitrid-

ing finish for long life. Fluorcarbon valve stem seals

are used on both valves. Stamped steel valve spring

seat, Valve springs, spring retainers, and locks are

conventional.

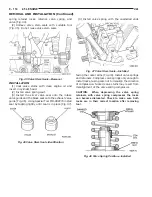

INTAKE MANIFOLD

This system is composed of a upper plenum (surge

tank) and manifold. This aluminum alloy manifold

has long runners to improve inertia. The plenum

chamber (surge tank) absorbs air pulsations created

during the suction phase of each cylinder. The lower

intake manifold is machined for six injectors and fuel

rail mounting.

EXHAUST MANIFOLDS

Both manifolds are made of cast nodular graphite

iron for heat resistance. Exhaust gasses from the left

cylinder bank, leave the left manifold through a

stainless steel pipe and bellows routed under the

engine to the right side manifold. The collected

exhaust from both manifolds are combined, and exit

to the exhaust pipe through a flex-joint.

DIAGNOSIS AND TESTING

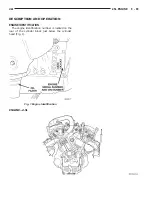

CHECKING ENGINE OIL PRESSURE

Check oil pressure using gauge at oil pressure

switch location. Oil pressure should be 41 kPa (6

psi.) at idle or 241 to 517 kPa (35 to 75 psi.) at 3000

RPM.

(1) Remove pressure sending unit and install oil

pressure gauge.

CAUTION:

If oil pressure is 0 at idle, Do Not Run

engine at 3000 RPM.

(2) Warm engine at high idle until thermostat

opens.

SERVICE PROCEDURES

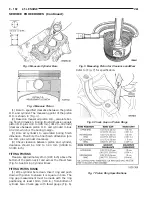

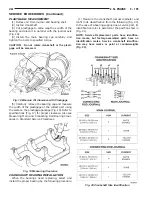

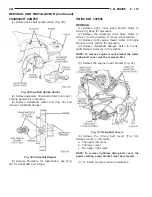

BORING CYLINDER

Examine cylinder walls for scuffs, scoring and mea-

sure cylinder bore for out-of-round or taper. If defec-

tive, bore cylinder to oversize. Measure at points

shown in (Fig. 3).

Four oversize pistons are available (0.25mm (.010

inch) 0.50mm (.020 inch) 0.75mm (.030 inch) and

1.0mm (.039 inch). Determine oversize piston on

basis of largest cylinder bore.

JA

2.5L ENGINE

9 - 101

DESCRIPTION AND OPERATION (Continued)

Summary of Contents for Stratus LHD 1997

Page 11: ......

Page 79: ......

Page 193: ......

Page 205: ......

Page 239: ......

Page 273: ......

Page 293: ......

Page 296: ...Charging System Schematic Typical JA CHARGING SYSTEM 8C 3 DIAGNOSIS AND TESTING Continued ...

Page 307: ......

Page 309: ......

Page 343: ...8D 34 IGNITION SYSTEM JA SPECIFICATIONS Continued ...

Page 377: ...8D 34 IGNITION SYSTEM JA SPECIFICATIONS Continued ...

Page 379: ......

Page 381: ......

Page 395: ......

Page 399: ......

Page 421: ......

Page 469: ......

Page 509: ......

Page 515: ......

Page 519: ......

Page 521: ......

Page 533: ......

Page 537: ......

Page 539: ......

Page 540: ......

Page 541: ......

Page 542: ......

Page 543: ......

Page 544: ......

Page 545: ......

Page 546: ......

Page 547: ......

Page 548: ......

Page 549: ......

Page 550: ......

Page 551: ......

Page 552: ......

Page 553: ......

Page 554: ......

Page 557: ......

Page 558: ......

Page 559: ......

Page 560: ......

Page 561: ......

Page 562: ......

Page 563: ......

Page 564: ......

Page 565: ......

Page 566: ......

Page 567: ......

Page 568: ......

Page 569: ......

Page 570: ......

Page 571: ......

Page 572: ......

Page 573: ......

Page 575: ......

Page 577: ......

Page 578: ......

Page 579: ......

Page 580: ......

Page 581: ......

Page 582: ......

Page 583: ......

Page 585: ......

Page 587: ......

Page 589: ......

Page 591: ......

Page 593: ......

Page 595: ......

Page 596: ......

Page 597: ......

Page 598: ......

Page 599: ......

Page 600: ......

Page 601: ......

Page 602: ......

Page 603: ......

Page 604: ......

Page 605: ......

Page 606: ......

Page 607: ......

Page 608: ......

Page 609: ......

Page 610: ......

Page 611: ......

Page 612: ......

Page 621: ......

Page 622: ......

Page 623: ......

Page 624: ......

Page 625: ......

Page 626: ......

Page 627: ......

Page 631: ......

Page 633: ......

Page 634: ......

Page 637: ......

Page 638: ......

Page 639: ......

Page 640: ......

Page 641: ......

Page 645: ......

Page 646: ......

Page 647: ......

Page 648: ......

Page 649: ......

Page 650: ......

Page 651: ......

Page 657: ......

Page 659: ......

Page 661: ......

Page 662: ......

Page 663: ......

Page 667: ......

Page 668: ......

Page 671: ......

Page 672: ......

Page 673: ......

Page 677: ......

Page 678: ......

Page 679: ......

Page 680: ......

Page 681: ......

Page 682: ......

Page 683: ......

Page 684: ......

Page 685: ......

Page 686: ......

Page 689: ......

Page 691: ......

Page 693: ......

Page 695: ......

Page 696: ......

Page 699: ......

Page 701: ......

Page 703: ......

Page 705: ......

Page 706: ......

Page 707: ......

Page 711: ......

Page 712: ......

Page 715: ......

Page 716: ......

Page 719: ......

Page 721: ......

Page 722: ......

Page 725: ......

Page 727: ......

Page 728: ......

Page 731: ......

Page 733: ......

Page 734: ......

Page 737: ......

Page 739: ......

Page 741: ......

Page 742: ......

Page 745: ......

Page 747: ......

Page 749: ......

Page 751: ......

Page 753: ......

Page 754: ......

Page 755: ......

Page 756: ......

Page 757: ......

Page 758: ......

Page 759: ......

Page 763: ......

Page 764: ......

Page 765: ......

Page 766: ......

Page 767: ......

Page 768: ......

Page 769: ......

Page 770: ......

Page 771: ......

Page 772: ......

Page 773: ......

Page 774: ......

Page 775: ......

Page 776: ......

Page 777: ......

Page 778: ......

Page 779: ......

Page 780: ......

Page 781: ......

Page 782: ......

Page 783: ......

Page 784: ......

Page 785: ......

Page 786: ......

Page 787: ......

Page 788: ......

Page 789: ......

Page 790: ......

Page 791: ......

Page 792: ......

Page 793: ......

Page 794: ......

Page 795: ......

Page 796: ......

Page 797: ......

Page 798: ......

Page 799: ......

Page 800: ......

Page 801: ......

Page 802: ......

Page 803: ......

Page 804: ......

Page 805: ......

Page 806: ......

Page 807: ......

Page 835: ...Fig 7 Body Splices 8W 95 6 8W 95 SPLICE LOCATIONS JA DESCRIPTION AND OPERATION Continued ...

Page 837: ......

Page 975: ...Adapter 6887 Camshaft Seal Installer 6863 9 138 2 5L ENGINE JA SPECIAL TOOLS Continued ...

Page 1001: ...13 6 BUMPERS AND FRAME JA SPECIFICATIONS Continued ...

Page 1065: ...Fuel Line Adapter 1 4 14 64 FUEL SYSTEM JA SPECIAL TOOLS Continued ...

Page 1071: ......

Page 1236: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC JA TRANSAXLE 21 105 SCHEMATICS AND DIAGRAMS Continued ...

Page 1237: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 106 TRANSAXLE JA SCHEMATICS AND DIAGRAMS Continued ...

Page 1238: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC JA TRANSAXLE 21 107 SCHEMATICS AND DIAGRAMS Continued ...

Page 1239: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 108 TRANSAXLE JA SCHEMATICS AND DIAGRAMS Continued ...

Page 1240: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC JA TRANSAXLE 21 109 SCHEMATICS AND DIAGRAMS Continued ...

Page 1241: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 110 TRANSAXLE JA SCHEMATICS AND DIAGRAMS Continued ...

Page 1242: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC JA TRANSAXLE 21 111 SCHEMATICS AND DIAGRAMS Continued ...

Page 1243: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 112 TRANSAXLE JA SCHEMATICS AND DIAGRAMS Continued ...

Page 1244: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC JA TRANSAXLE 21 113 SCHEMATICS AND DIAGRAMS Continued ...

Page 1245: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 114 TRANSAXLE JA SCHEMATICS AND DIAGRAMS Continued ...

Page 1246: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC JA TRANSAXLE 21 115 SCHEMATICS AND DIAGRAMS Continued ...

Page 1247: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 116 TRANSAXLE JA SCHEMATICS AND DIAGRAMS Continued ...

Page 1248: ...41TE TRANSAXLE HYDRAULICSCHEMATIC JA TRANSAXLE 21 117 SCHEMATICS AND DIAGRAMS Continued ...

Page 1271: ......

Page 1287: ...SPECIFICATIONS SUNROOF COMPONENTS 23 16 BODY JA ...

Page 1318: ...SPECIAL TOOLS BODY REMOVER MOLDINGS C 4829 STICK TRIM C4755 JA BODY 23 47 ...

Page 1319: ......

Page 1321: ...Fig 1 Floor Console 23 2 BODY JA REMOVAL AND INSTALLATION Continued ...

Page 1359: ......

Page 1387: ......

Page 1401: ...FASTENER IDENTIFICATION 6 INTRODUCTION JA GENERAL INFORMATION Continued ...

Page 1404: ...METRIC CONVERSION JA INTRODUCTION 9 GENERAL INFORMATION Continued ...

Page 1512: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC JA TRANSAXLE 21 105 SCHEMATICS AND DIAGRAMS Continued ...

Page 1513: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 106 TRANSAXLE JA SCHEMATICS AND DIAGRAMS Continued ...

Page 1514: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC JA TRANSAXLE 21 107 SCHEMATICS AND DIAGRAMS Continued ...

Page 1515: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 108 TRANSAXLE JA SCHEMATICS AND DIAGRAMS Continued ...

Page 1516: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC JA TRANSAXLE 21 109 SCHEMATICS AND DIAGRAMS Continued ...

Page 1517: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 110 TRANSAXLE JA SCHEMATICS AND DIAGRAMS Continued ...

Page 1518: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC JA TRANSAXLE 21 111 SCHEMATICS AND DIAGRAMS Continued ...

Page 1519: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 112 TRANSAXLE JA SCHEMATICS AND DIAGRAMS Continued ...

Page 1520: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC JA TRANSAXLE 21 113 SCHEMATICS AND DIAGRAMS Continued ...

Page 1521: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 114 TRANSAXLE JA SCHEMATICS AND DIAGRAMS Continued ...

Page 1522: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC JA TRANSAXLE 21 115 SCHEMATICS AND DIAGRAMS Continued ...

Page 1523: ...41TE TRANSAXLE HYDRAULIC SCHEMATIC 21 116 TRANSAXLE JA SCHEMATICS AND DIAGRAMS Continued ...

Page 1524: ...41TE TRANSAXLE HYDRAULICSCHEMATIC JA TRANSAXLE 21 117 SCHEMATICS AND DIAGRAMS Continued ...