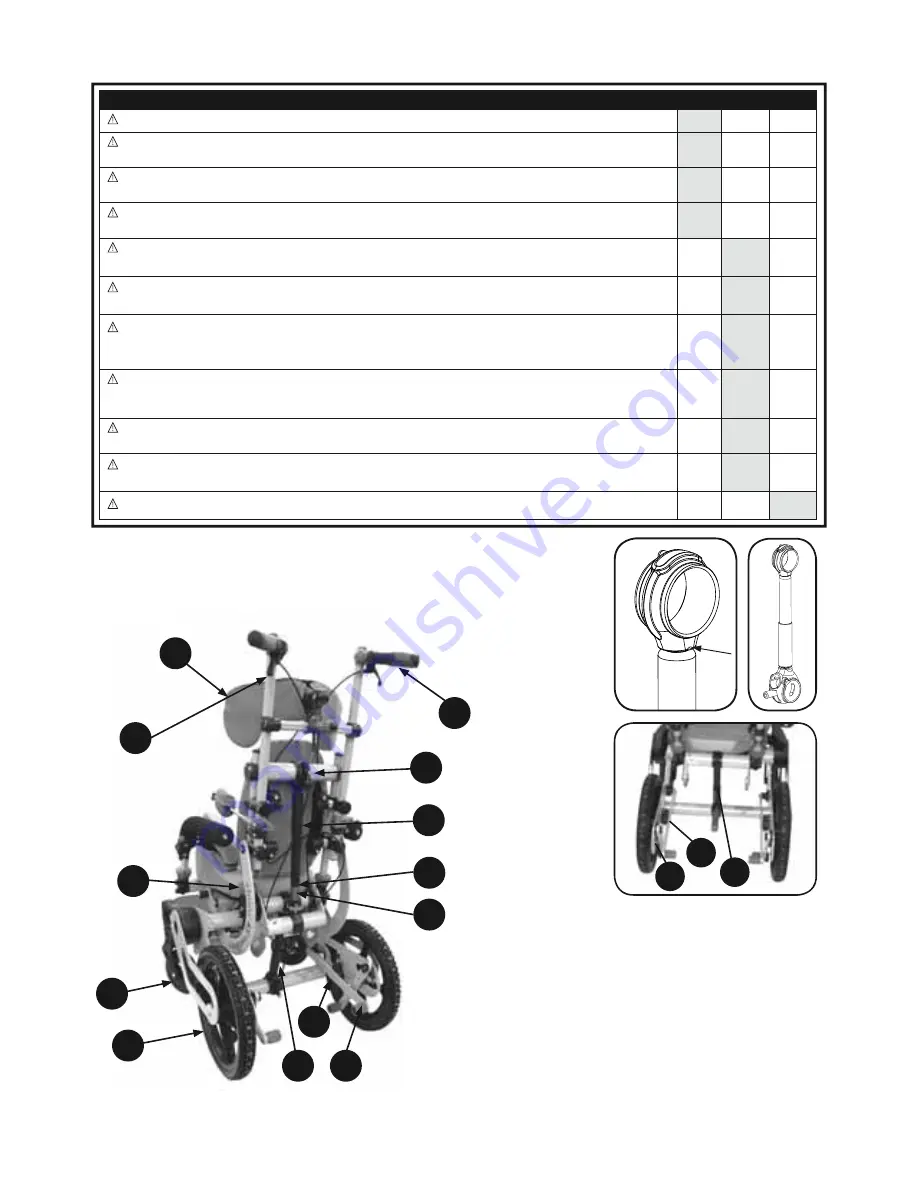

Key Checks

Daily

Weekly

Monthly

1.

Handle Grips - Ensure grips are fi xed in height and rubber sleaves secure

x

2.

Collet Locking Cap - Ensure all caps are tightened. The caps are fully tight when there is a 2-3 mm gap between the cap and

the shoulder of the collet bracket.

x

3.

Brake Assembly - Ensure the brake lever moves freely into its operative and non - operative position. Ensure all bolts are

tight. Please note : As the rear tyre wears, the brakes become less eff ective.

x

4.

Ensure all upholstered parts are dry, clean and free from creases. Ensure all body supports are tight and correctly positioned.

Ensure all harnesses are untangled and correctly positioned.

x

5.

Castors - Ensure the castors rotate freely in every direction and remove any hair or dirt that has collected between the

bearings and fork. Ensure grips are free from stones / debris. Ensure the castor is not bent and that all bolts are tightened securely.

x

6.

Rear Wheels - Ensure the wheel rotates freely. Ensure grips are free from stones / debris. Do not use if the wheel is cracked,

broken or bent.

x

7.

Gas Strut (tilt in space) - Ensure the gas strut compresses / decompresses. Ensure the gas strut is secured to both the

upper pivot bracket

7A

ensuring no gap at

7B

and the lower gas strut release bracket

7C

. A safety device is fi tted to your Chunc

wheelbase to prevent a rearward fall of the client in the unlikely event of a gas strut failure.

x

8.

Gas strut (backrest recline) - Ensure the gas strut compresses/decompresses. Ensure the gas strut is secured to both the

upper gas strut release bracket

8A

and the lower releasable coupling

8C

ensuring no gap at

8B

(as perfi g detailing

7B

). Check

security of releasable coupling assembly.

x

9.

Tripping levers and cables - check for damage or wear to levers and cables. Ensure cable has correct tension to activate gas

strut release.

x

10.

Anti Tips - Ensure the anti tip device moves freely from operative to non - operative positions. Where possible keep the

anti tip in its operative (outward) position.

x

11.

Inspect your wheelchair checking for damage or excessive wear. Check the security of all fasteners and fi xings.

x

Chunc Recline and Tilt 45

75

SM375 Series

Fitting/Adjusting Spare Parts

Always refer/quote date of manufacture and serial number when ordering spare parts.

Not all parts are available individually. See chunc spare parts list www.chunc.com.

Fasteners with thread lock are used in many cases. If these connections are opened ensure they are replaced with

thread lock applied.

Note: Chunc 45

54

Recline Small shown with various options.

d lock applied.

1

2

10

6

4

3

8B

7

5

8C

8A

8

9

Basic Tools for Maintenance

• 4mm Hex/Allen Key

• 5mm Hex/Allen Key

• 6mm Hex/Allen Key

• 10mm Spanner

• 13mm Spanner

• 17mm, 10 Gauge Spanner

• Philips Screwdriver

• Loctite 248 or equivalent

• Loctite 270 or equivalent

• Loctite 480 or equivalent

• Copper grease

• Silicon spray (food grade)

• Torque wrench (optional) with hex sockets

7B

7A

7C

7

8

3

Additional Chunc User Guide & Combined Options Manual HRS 1160-1-11 C/N 5801 ISSUE 3 - 1/5/2012

For Complete Chunc Recline and Tilt 45

75

SM375 Series Maintenance & Spare Parts Manual go to www.chunc.com (Doc HRS 1164-2-12)