31

Pipe installation

When doing the piping connection, please do the following:

•

Please don't let the pipe and the parts in the unit collide each other.

•

When connecting the pipes, close the valves fully.

• Protect the pipe end against and water, impurities (welding after being flatted, or being sealed with adhesive

tape).

•

Bend the pipe as large semi-diameter as possible(over 4 times of the pipe diameter).

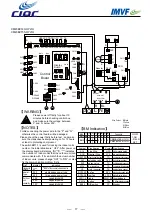

• The connection between outdoor liquid pipe and the distributing pipe is flared type. Please expand the pipe with

the special tool for R410A after installing the expanding nut. But if the projecting pipe length has been adjusted

with the copper pipe gauge, you can use the original tool to expand the pipe.

•

Since the unit is with R410A, the expanding oil is ester oil, not the mineral oil.

• When doing the flare connection, please do the following: When connecting the expanding pipe, fasten the pipes

with double-spanner. The torque refers to the former info.

•

The outdoor gas pipe and the refrigerant distributing pipe, as well the refrigerant distributing pipe and the branch

pipe should be welded with hard solder.

• Weld the pipe at the same time charge the nitrogen. Or it will cause a number of impurity (a film of oxidation) to

clog the capillary and the expansion valve, further cause the deadly failure.

• Protect the pipe end against the water, impurity into the pipes (welding after being flat, or being sealed with

adhesive tape).

• The refrigerant pipe should be clean. The nitrogen should flow under the pressure of about 0.2Mpa and when

charging the nitrogen, stop up the end of the pipe by hand to enhance the pressure in the pipe, then loose the

hand (meanwhile stop up the other end).

•

When connecting the pipes, close the valves fully.

•

When welding the valve and the pipes, use the wet cloth to cool down the valve and the pipes.

Pipe outer diameter

(mm)

A

Ø6.35

9.1

Ø9.52

13.2

Ø12.7

16.6

Ø15.88

19.7

Expanding pipe: A(mm)

Pipe outer diameter

(mm)

When it is hard pipe

Special tool

for R410A

The former

tool

Ø6.35

0-0.5

1.0-1.5

Ø9.52

Ø12.7

Ø15.88

Projecting length of pipe to be expanded: B(mm)

Seal the pipe end with adhesive tape or the stopper to

increase the resistance, fill up the pipe with nitrogen.

Only nitrogen gas

can be used

Brazing

<N2>

Taping

Adhesive tape

Flat

Brazing

1st side

Hand

2nd side

Source valve

0.2MPa