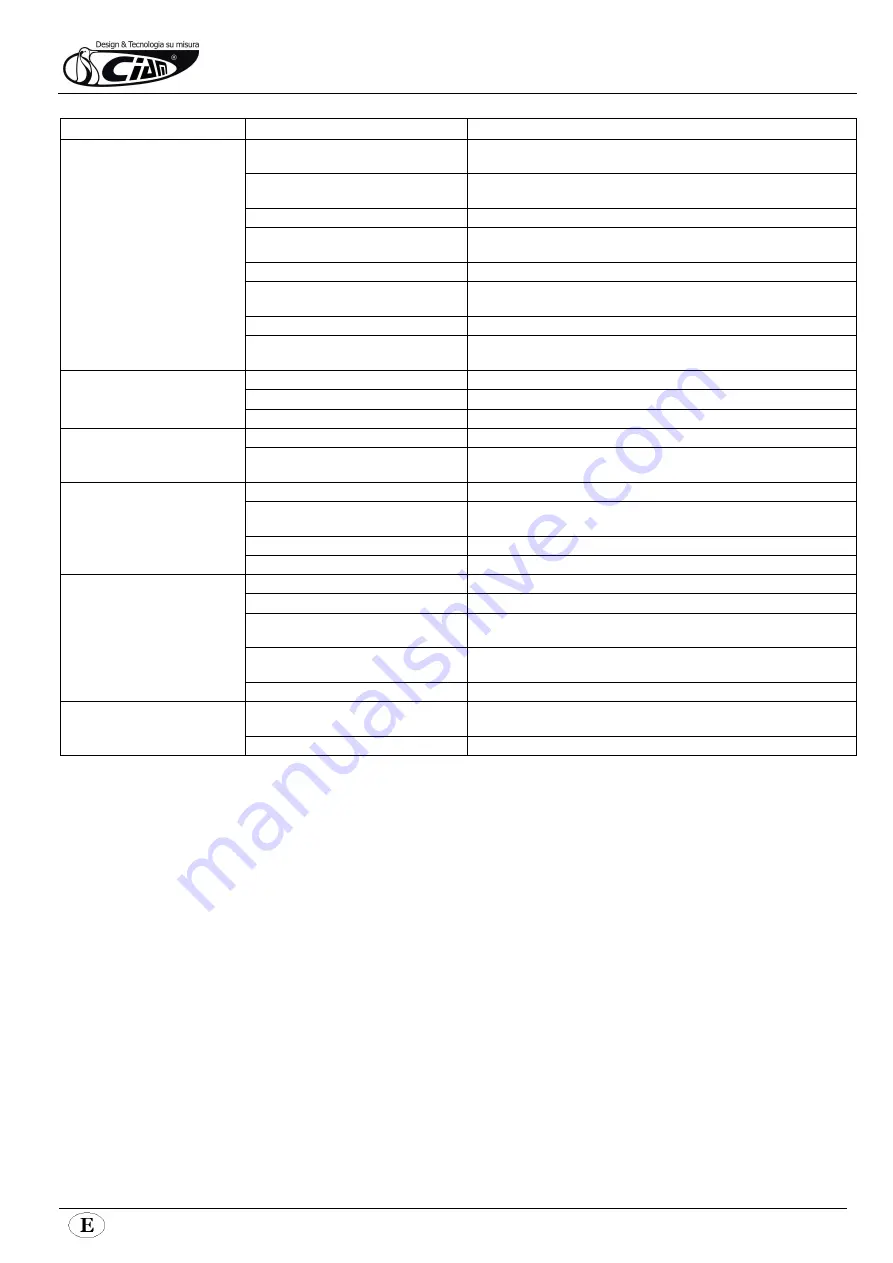

DEFECT

PROBABLE CAUSES

POSSIBLE REMEDIES

The compressor works constantly

or for too long periods

The temperature inside the room is too

high

The compressor can only work constantly if there is no chance of decreasing

room temperature (for instance with a.c. system)

The temperature of the compressors’ room

is too high (remote comp.)

See above

The air condenser is blocked

Clean the condenser carefully

Cooling air flow of the water condenser is

not sufficient

Check the efficiency of the regulation valve and make sure that taps are

turned on

Lack of refrigerant

Identify the eventual leak and refill with refrigerant

Internal ventilation is not sufficient

Restore a proper ventilation by replacing the faulty fans or by removing the

eventual obstacle

Evaporators are extremely clogged

Operate a complete defrost cycle

The temperature set on the thermostat is

too low

Adjust temperature settings

Temperature is not displayed on

the digital panel

Flat battery

Replace battery

Sensor does not work properly

Replace digital thermostat

Faulty electronics

Replace digital thermostat

Defrost water missing

Water drain pipes are blocked

Remove the obstacle

Defrost cycle is not efficient

Verify the efficiency of control panel (slave module, sensor, solenoid valve..)

and the position of the end cycle sensor

Lighting is not working

The switch is off

Turn the switch on

The neon lamp is not properly fitted in its

case

Ad just the lamp by rolling it

Exhausted lamp

Replace the lamp

Ballasts or starter are not efficient

Replace faulty components

The unit is too noisy

Vibrations of internal plates

Tighten all the fixing screws

Internal fans are not fixed well

See above

Fans’ blades are not fixed well

Replace faulty fans. If there is friction between the blades and some ice

formation, then act on defrost cycle settings

Pipes are in contact with other parts of

equipment

Avoid any contact between pipes and other parts; a constant rubbing might

wear the pipes out and give way to refrigerant leaking

The unit is not well levelled

Adjust the levelling

Condensation water forming on the

glasses

Transformer is not working

Check that the transformer is correctly supplied - Verify the correct

functioning of the transformer fuse - Replace the transformer

Heating circuit interrupted

Replace the glasses

Summary of Contents for CIAO GEL 12

Page 11: ......