POWERCIAT LX ST/HE/XE

EN-

6

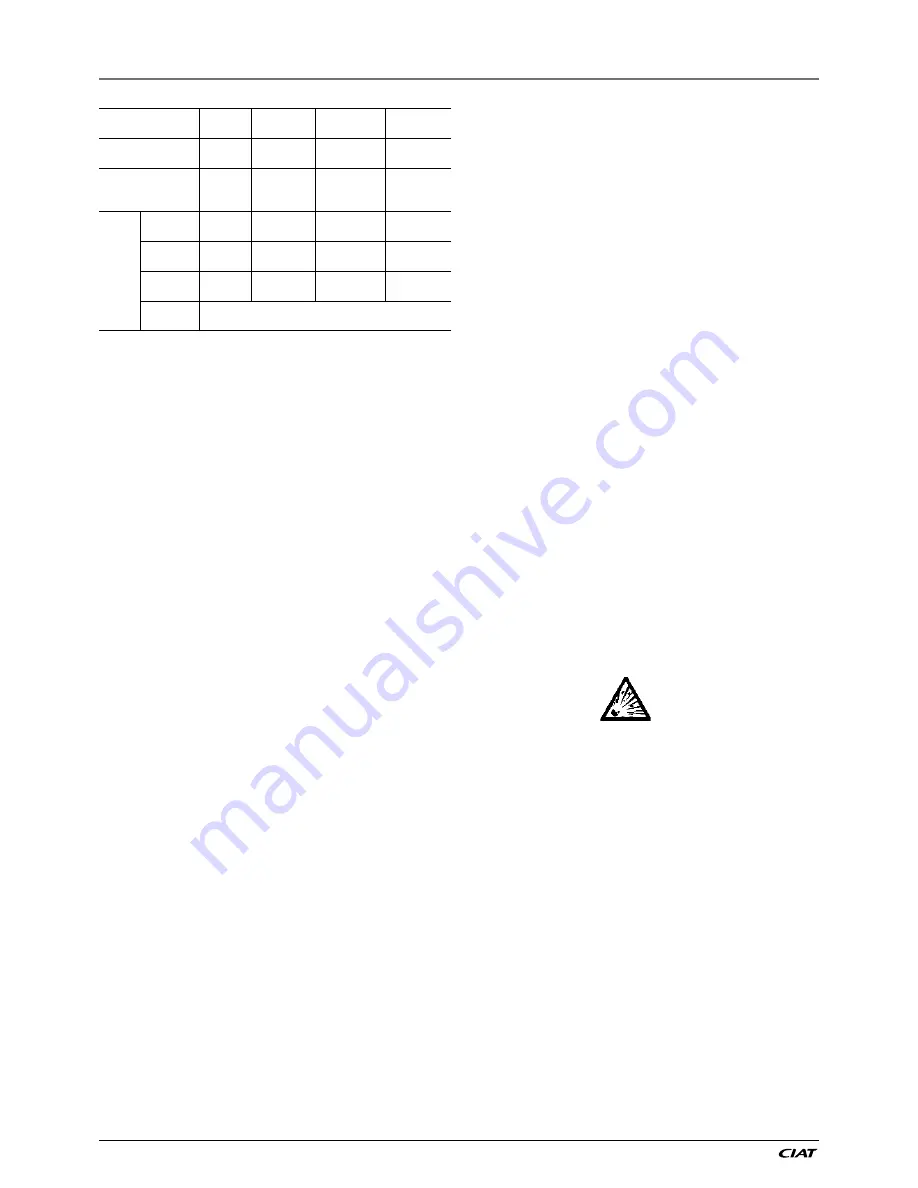

System WITHOUT

leakage detection

No Check

12 Months

6 Months

3 Months

System WITH leakage

detection

No Check

24 Months

12 Months

6 Months

Refrigerant

charge/circuit

(CO

2

equivalent)

< 5 Tons

5 ≤ Charge

< 50 Tons

50 ≤ Charge

< 500 Tons

Charge

> 500 Tons*

Refrigerant charge/

Circuit (kg)

R134A

(GWP 1430)

Charge

< 3.5 kg

3.5 ≤ Charge

< 34.9 kg

34.9 ≤ Charge

< 349.7 kg

Charge

> 349.7 kg

R407C

(GWP 1774)

Charge

< 2.8 kg

2.8 ≤ Charge

< 28.2 kg

28.2 ≤ Charge

< 281.9 kg

Charge

> 281.9 kg

R410A

(GWP 2088)

Charge

< 2.4 kg

2.4 ≤ Charge

< 23.9 kg

23.9 ≤ Charge

< 239.5 kg

Charge

> 239.5 kg

HFO’s:

R1234ze

No requirement

*

From 01/01/2017, units must be equipped with a leak detection system.

8. A logbook must be maintained for equipment

subject to periodic leak tests. It should contain

the quantity and the type of fluid present in the

installation (added and recovered), the quantity

of recycled fluid, the date and result of the leak

test, the name of the operator and the name of

his/her company, etc.

9. Contact your local dealer or installer if you have any

questions.

The information on operating inspections given in annex C

of standard EN 378 can be used if no similar criteria exist

in the national regulations.

While working in the fan area, especially when grilles or

casings are removed, disconnect the fan power supply to

prevent their automatic restart.

PROTECTION DEVICE CHECKS:

If no national regulations exist, check the protection devices

on site in accordance with standard EN 378: Once a year for

the high-pressure switches, every five years for external

relief valves.

The company or organisation that conducts a pressure switch

test must establish and implement detailed procedures for:

-

Safety measures

-

Measuring equipment calibration

-

Validating operation of protective devices

-

Test protocols

-

Recommissioning of the equipment.

Consult CIAT Service for this type of test. In this document, CIAT

only outlines the principle for a test without removal of the

pressure switches:

-

Check and record the nominal values for triggering the

pressure switches and external relief devices (valves,

if present).

-

Be ready to switch-off the main disconnect switch of the

power supply if the pressure switch does not trigger (avoid

over-pressure or excess gas in case of valves on the

high-pressure side with the recovery condensers)

-

Connect a pressure gauge protected against pulsations

(filled with oil with maximum pointer if mechanical),

preferably calibrated (the values displayed on the user

interface may be inaccurate in an instant reading because

of the scanning delay applied in the control)

-

Complete an HP Test as provided by the software (refer to

the Control IOM for details).

If the machine operates in a corrosive environment, inspect

the protection devices more frequently.

Regularly carry out leak tests and immediately repair any

leaks. Ensure regularly that the vibration levels remain

acceptable and close to those at the initial unit start-up.

Before opening a refrigerant circuit, purge and consult the

pressure gauges.

Change the refrigerant after an equipment failure, following

a procedure such as the one described in NF E29-795 or

carry out a refrigerant analysis in a specialist laboratory.

If the refrigerant circuit is opened for a day or less, block all

openings; fill the circuit with a nitrogen charge if open for

longer periods.

1.4 - Repair safety considerations

All installation parts must be maintained by the personnel in charge,

in order to avoid material deterioration and injuries to people. Faults

and leaks must be repaired immediately. The authorized technician

must have the responsibility to repair the fault immediately. After

each repair of the unit, check the operation of the protection devices

and create a report of the parameter operation at 100%.

Comply with the regulations and recommendations in unit and HVAC

installation safety standards, such as: EN 378, ISO 5149, etc.

If a leak occurs or if the refrigerant becomes contaminated

(e.g. by a short circuit in a motor) remove the complete charge

using a recovery unit and store the refrigerant in mobile

containers.

Repair the leak detected and recharge the circuit with the total

R-134a charge, as indicated on the unit name plate. Certain parts

of the circuit can be isolated. Only charge liquid refrigerant

R-134a at the liquid line.

Ensure that you are using the correct refrigerant type before

recharging the unit. Charging any refrigerant other than the

original charge type (R-134a) will impair machine operation

and even destroy the compressors. The compressors

operating with this refrigerant type are lubricated with a

synthetic polyolester oil.

RISK OF EXPLOSION:

Never use air or a gas containing oxygen during leak tests

to purge lines or to pressurise a machine. Pressurised air

mixtures or gases containing oxygen can be the cause of

an explosion.

Only use dry nitrogen for leak tests, possibly with an appropriate

tracer gas.

If the recommendations above are not observed, this can have

serious or even fatal consequences and damage the installation.

Never exceed the specified maximum operating pressures.

Verify the allowable maximum high- and low-side test

pressures by checking the instructions in this manual and

the pressures given on the unit name plate.

1 - INTRODUCTION