CIB UNIGAS - M039208CA

10

Matching the burner to the boiler

The burners described in this manual have been tested with combustion chambers that comply with EN676 regulation and whose

dimensions are described in the diagram . In case the burner must be coupled with boilers with a combustion chamber smaller in dia-

meter or shorter than those described in the diagram, please contact the supplier, to verify that a correct matching is possible, with res-

pect of the application involved. To correctly match the burner to the boiler verify the necessary input and the pressure in combustion

chamber are included in the burner performance curve; otherwise the choice of the burner must be revised consulting the burner manu-

facturer. To choose the blast tube lenght follow the instructions of the boiler manufacturer. In absence of these consider the following:

z

Cast-iron boilers, three pass flue boilers (with the first pass in the rear part): the blast tube must protrude no more than 100 mm into

the combustion chamber.

z

Pressurised boilers with flame reversal: in this case the blast tube must penetrate at least 50 - 100 mm into combustion chamber in

respect to the tube bundle plate.

The length of the blast tubes does not always allow this requirement to be met, and thus it may be necessary to use a suitably-sized

spacer to move the burner backwards or to design a blast tube tha suites the utilisation (please, contact the manifacturer).

Burner ignitor

Execute the burner ignitor connections as follows:

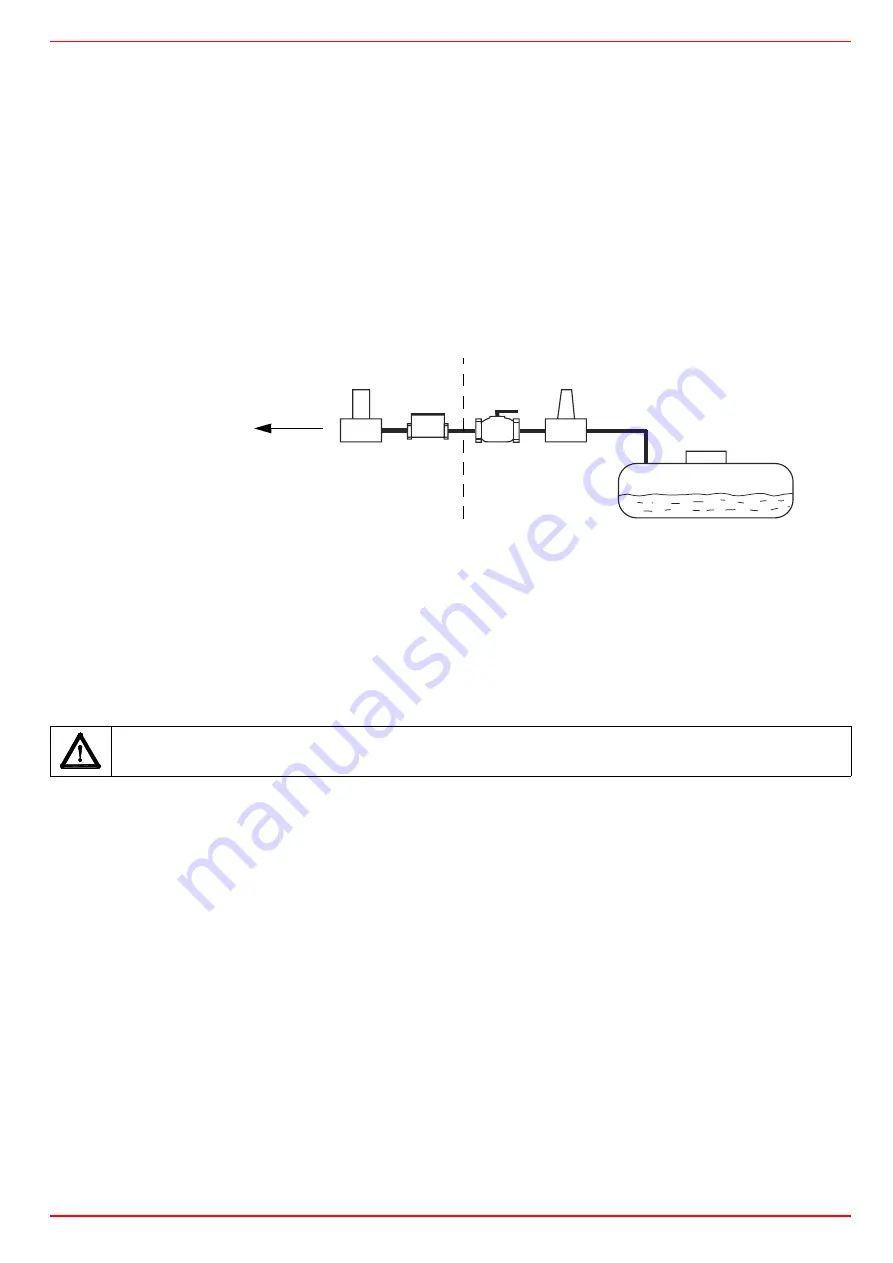

Legenda

1 Gas valve

2 Gas filter

3 Manual cutoff valve

4 Pressure reducer

5 Tank

Gas supply:

LPG

Gas pressure:

100 mbar

Once the gas train in installed, execute the electrical connections for all its items (gas valves group, pressure switch).

ATTENTION:

once the gas train is mounted according to the diagram on picture above, the gas proving test mus be perfor-

med, according to the procedure set by the laws in force.

MANIFACTURER

INSTALLER

LPG

1

2

3

5

4

Summary of Contents for TN 1030

Page 2: ......

Page 20: ...CIB UNIGAS M039208CA 20 Fig 9 Hydraulic diagram 3ID0014 Two or more burners configuration...

Page 23: ...CIB UNIGAS M039208CA 23 z BERGONZO NOZZLES Fig 11...

Page 24: ...CIB UNIGAS M039208CA 24 Fig 12...

Page 25: ...CIB UNIGAS M039208CA 25 Fig 13...

Page 26: ...CIB UNIGAS M039208CA 26 Fig 14...

Page 43: ......