OPERATING MANUAL

MANUAL ARC (MMAW) WELDING

7-4

Manual 0-5586

Art# A-07693

Figure 7-8: Overhead Position, Butt Weld

Art # A-07694

Figure 7-9: Overhead Position, Fillet Weld

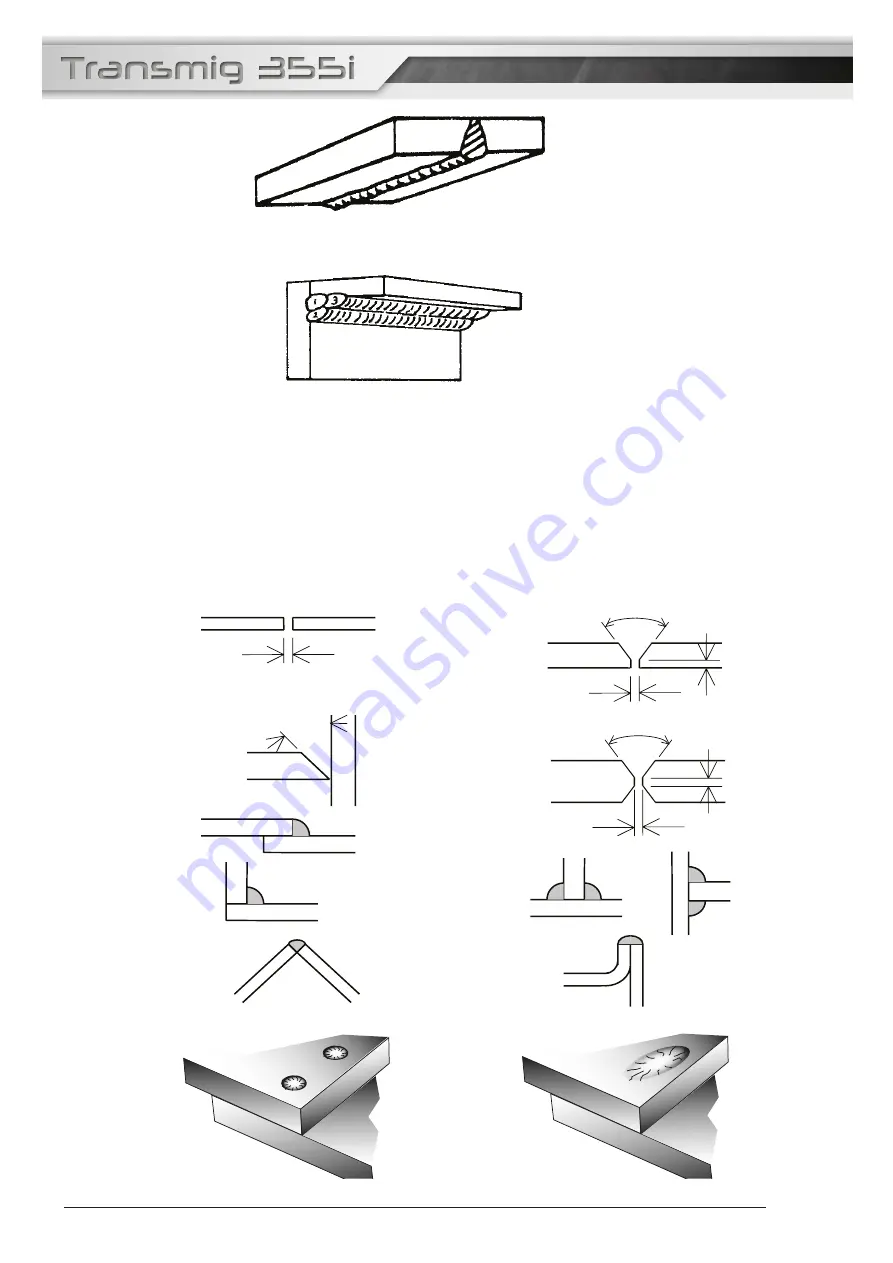

Joint Preparations

In many cases, it will be possible to weld steel sections without any special preparation. For heavier sections

and for repair work on castings, etc., it will be necessary to cut or grind an angle between the pieces being

joined to ensure proper penetration of the weld metal and to produce sound joints.

In general, surfaces being welded should be clean and free of rust, scale, dirt, grease, etc. Slag should be

removed from oxy-cut surfaces. Typical joint designs are shown in Figure 7-10.

Gap varies from

1.6mm (1/16”) to 4.8mm (3/16”)

depending on plate thickness

Joint

Open Square Butt

1.6mm (1/16” ) max

1.6mm (1/16”)

Single Vee Butt Joint

Not less than

70

°

Double Vee Butt Joint

1.6mm (1/16”)

Lap Joint

Tee Joints

(Fillet both sides of the

joint)

Edge Joint

Fillet Joint

Corner Weld

Plug Weld

Plug Weld

Not less than

70

°

Single Vee Butt Joint

Not less than

45

°

1.6mm (1/16”) max

Art # A-07695_AE

Figure 7-10: Typical Joint Designs for Arc Welding

Summary of Contents for Transmig 355i

Page 8: ...This Page Intentionally Blank ...

Page 14: ...OPERATING MANUAL GENERAL INFORMATION 1 6 Manual 0 5586 This Page Intentionally Blank ...

Page 24: ...OPERATING MANUAL INTRODUCTION 2 10 Manual 0 5586 This Page Intentionally Blank ...

Page 28: ...OPERATING MANUAL INSTALLATION 3 4 Manual 0 5586 This Page Intentionally Blank ...

Page 84: ...OPERATING MANUAL TIG GTAW WELDING 6 10 Manual 0 5586 This Page Intentionally Blank ...

Page 110: ...OPERATING MANUAL KEY SPARE PARTS 9 4 Manual 0 5586 This page intentionally blank ...

Page 112: ...OPERATING MANUAL APPENDIX A 2 Manual 0 5550 This Page Intentionally Blank ...

Page 115: ...OPERATING MANUAL Transmig 220i This Page Intentionally Blank ...