39

BLITZ

5-1996

UMAP087

UMAP089

UMAP088

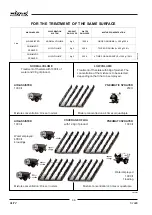

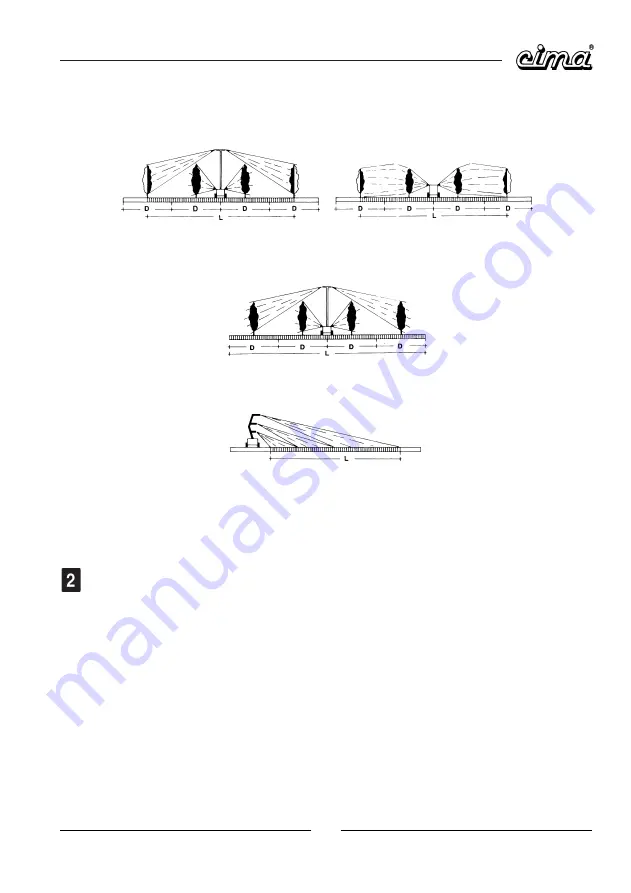

3 = THREE ROWS,

Lm = 3D (mt 9)

The virtual width corresponds to a strip of land three times as wide as the distance between the rows. It requires a passage

every two rows.

4 = FOUR ROWS,

Lm= 4D (mT 12)

The virtual width corresponds to a strip of land four times as wide as the distance between the rows. It requires a passage

every three rows.

SIDE FULL FIELD

The virtual width corresponds to the distance in meters actually covered by the pulverization.

For those who are going to employ an sprayer for the firs time, it is suggested that the "virtual width of treatment" be

determined after you have verified in practice its coverage capacity. In fact, during the season, this width may change

with respect to the moment of treatment: in some cultivations more rows are covered at the beginning of the vegetation

cycle than those covered during the period of maximum vegetation.

Feed speed = "km/h"

This is the speed of the tractor-sprayer operative unit when carrying out treatment.

It must be decided in practice on the field, depending on the ground conditions, how the cultivation is planted and the

type of sprayer employed. It is also essential to select a gear which respects the functional characteristics of the machine.

Normally, a speed lower than that used with traditional low volume apparatuses increases the treatment quality and

efficiency without reducing its operative capacity.

THE FEED SPEED IN km/h IS DEDUCED FROM THE SPEEDS DECLARED FOR EACH TRACTOR, FOR THE GEAR

SELECTED FOR TREATMENT.

Knowing the length in meters of a row (mt) and calculating the time in seconds (sec) to cover it, it is possible to check

or calculate the feed speed.

It is sufficient to use the formula:

"mt x 3,6 : sec = km/h"

(row length in metres, multiplied by 3,6 and divided for the

seconds spent = km/h).