35

Plus 42 - 45 - 50 - 55 - 55S - 55E

11-2000

9

SHAKING OF THE MIXTURE

9

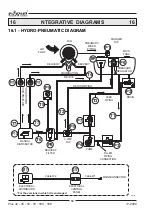

The hydraulic and pneumatic circuits assembled within the tank provide a double system for shaking

the mixture: through the water from the pump and by means of the air from the fan, simultaneously.

The pneumatic shaking can be excluded when products causing excessive foaming are used. In this

case it is sufficient to close the plunger tap located above the tank. When it is reopened, check that

the air outlet holes are not blocked.

Before starting the treatment it is essential to shake the mixture in the tank, re-

circulating it completely for as long as it takes to make it homogeneous.

The shaking action must be carried out with the pressure regulator (P6) open in

case of first utilisation of the machine, or in the position already selected for the

treatment in progress or for the preceding one. The plunger tap above the tank

must also be open if the treatments involved don’t use agro-chemicals generating

excessive foam. This operation is of essential importance in obtaining a uniform

distribution of the chemical’s active agent over the whole crop to be treated.

Should the activity need to be interrupted during a treatment with the spray atomiser, keep the shaking

activated until the treatment is resumed. Should this be stopped and deferred to a later stage, the mixture

that has remained in the tank must be shaken again properly.

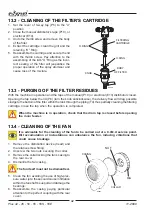

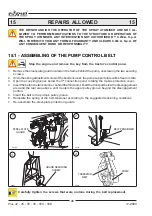

10 DISCHARGING OF THE HYDRAULIC CIRCUIT 10

- Stop the tractor and remove the key from the control panel.

- Wear suitable protective clothing and accessories in order to avoid

contamination by contact or inhalation of the mixture.

- Carry out the discharging in a suitable and properly geared area for the

collection of the washing liquid..

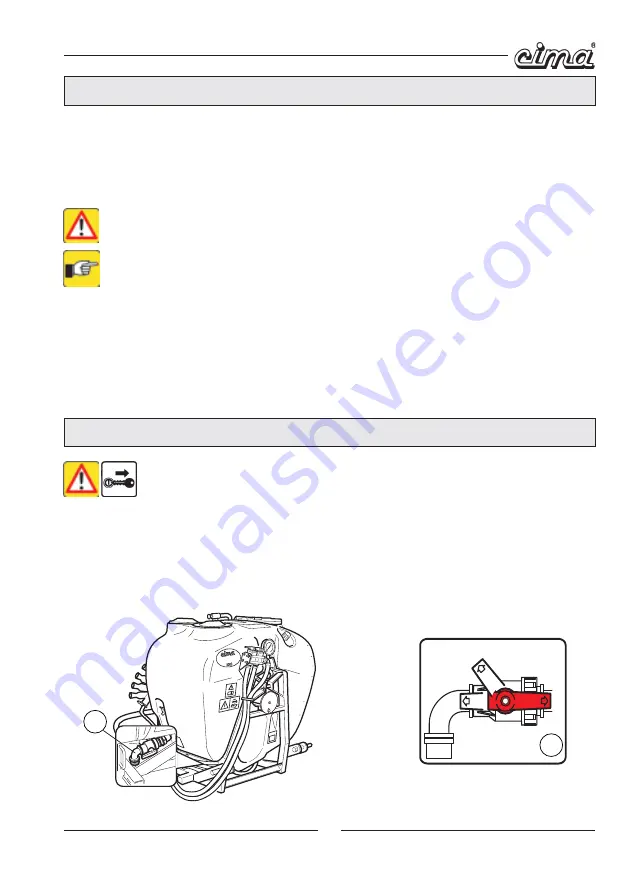

The operation is carried out through the drain plug P2:

1. Unscrew the drain plug only when the tap’s lever is in the “a” position. (Drain closed).

2. Turn the lever to position “b”. (Drain open)..

P2

00133

00033

b

c

a

P2