Plus 42 - 45 - 50 - 55

09-2008

10

Empty packaging and contaminated containers to be done away with cannot be

dispersed, burned or buried.

The washing water for the cisterns and the tools utilised for the preparation of

mixtures cannot be emptied on the ground, spilled into the sewage system or in

waterways and rivers.

The disposal of special wastes is regulated by specific norms. In order to perform this operation it is

necessary to obtain the relevant information from the Local Offices specifically appointed to rule on

this subject. The non compliance with these regulations can cause considerable damage to persons

and animals as well as polluting the environment.

3.5.4 - Personal means of protection

The toxicity of agro-chemicals forces persons working with them to wear adequate protective clothing

and accessories in order to avoid risks of contamination by contact or inhalation.

In each of the following work stages:

— filling of tanks and adding of the agro-chemical,

— dusting and spraying,

— adjusting of the sprayer,

— emptying and cleaning of the tank,

— replacement of the agro-chemical,

— maintenance interventions,

it is necessary to wear personal protection clothing and accessories.

The following must be worn:

— Polyethylene or polyvinyl gloves.

— Full, waterproof cotton overalls, in order to

guarantee transpiration, fitted with polypro-

pylene side flaps.

In commerce, one-time ‘tyvek’ overalls are

available which, after use (see picture), must

be disposed of according to the modalities

applicable to toxic waste.

— A protective half-mask in polychloroprene

rubber with 1 or 2 filters. Filters for gases and

organic fumes, of European A1-class va-

pours, are envisaged and these can be

combined with anti-dust models of P1 Euro-

pean class, for harmful mists and powders,

or P2, for harmful and toxic mists and powders.

The filters must be replaced:

- when the smell/taste of agro-chemicals can be detected, and that of active A1-

class carbons;

- when difficulty in breathing is experienced for the anti-dust filters of class P1 and

P2.

In any case it is necessary to make use of all personal means of protection as

suggested by the manufacturers.

00073

09-2008

Plus 42 - 45 - 50 - 55

59

15

REPAIRS ALLOWED

15

THE OWNER AND/OR THE OPERATOR OF THE SPRAYER ARE NOT PERMITTED TO MODIFY

THE STRUCTURE OR THE SPECIFIC OPERATION OF THE SPRAYER ITSELF. ANY REPAIR-

ING INTERVENTION HAS TO BE CARRIED OUT EITHER AT THE DEALERS’ OR AT THE

C.I.M.A. S.p.A. AUTHORIZED WORKSHOPS, OTHERWISE ANY KIND OF WARRANTY

IMMEDIATELY CEASES AND C.I.M.A. S.p.A. IS CLEARED OF ANY CONSEQUENT AND/OR

IMPLIED RESPONSIBILITY.

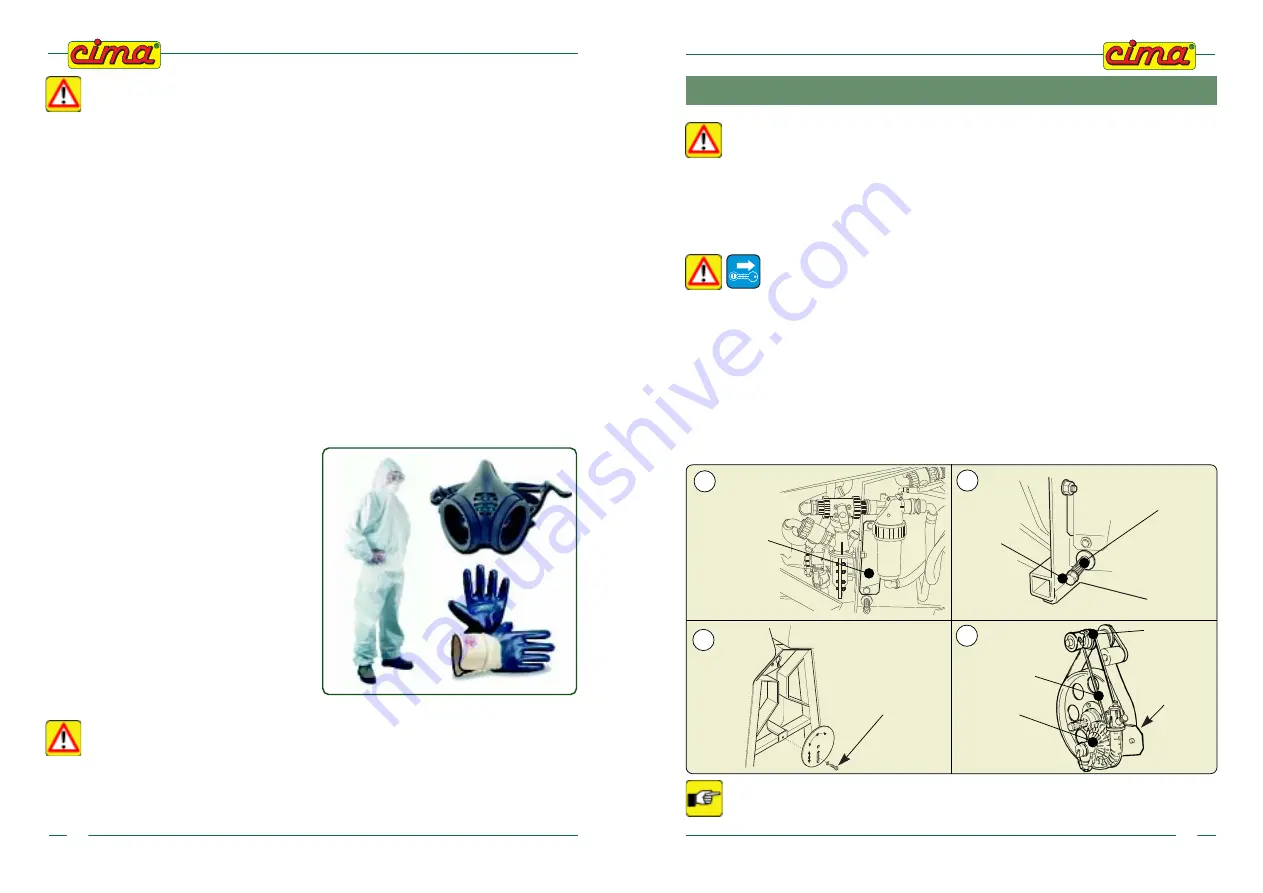

15.1 - REPLACEMENT OF PUMP CONTROL BELT

Stop the engine and remove the key from the tractor’s control pane

l

.

1.

Remove the steel-plate guard located on the frame behind the pump, unscrewing the two securing

screws.

2.

Completely unscrew the tightener spring adjusting screw: the pump support plate will so freely turn.

3.

Unscrew the fixing screw and turn the mobile protection cover to approach the tunnel of the

disengagement.

4.

Insert the pump control belt into the tunnel of fan disengagement. Feed the front part below the

disengagement area and the rear area above, until it enters the upper pulley groove beyond the

disengagement portion.

5.

Insert the belt in the pump’s pulley groove.

6.

Reinstate the spring of the belt-tensioner according to the suggested tensioning conditions.

7.

Re-assemble the steel-plate protection guards.

Carefully tighten the screws that were undone during the belt replacement.

1

3

2

4

00091

GUARD SECURING

SCREW

00308

STEEL-PLATE

GUARD

00038

00014

TRAPEZOID

BELT

PUMP

BELT-TENSIONER

00100

ADJUSTING

SCREW

LOWER

PULLEY

UPPER

PULLEY