Plus 42 - 45 - 50 - 55

09-2008

16

P4

P6

P12

BS

BP

P7

T6

T1

T2

T9

TR

T4

E9

P1

P13

d

b

a

c

P14

m.

AUTO

P

RO

ON

OFF

1

2

3

1

2

3

Pro

D

MAN

2xP

OFF

ON

3

2

1

1

2

3

G

1 2 3 4 5 6 7 8 9 10 11 12

Ha

Km/H

Bar

L/Ha

2.0

250

3.0

12.58

E8

P8*

E5

P11

T5

b

c

a

P2

E.P.A. Versions

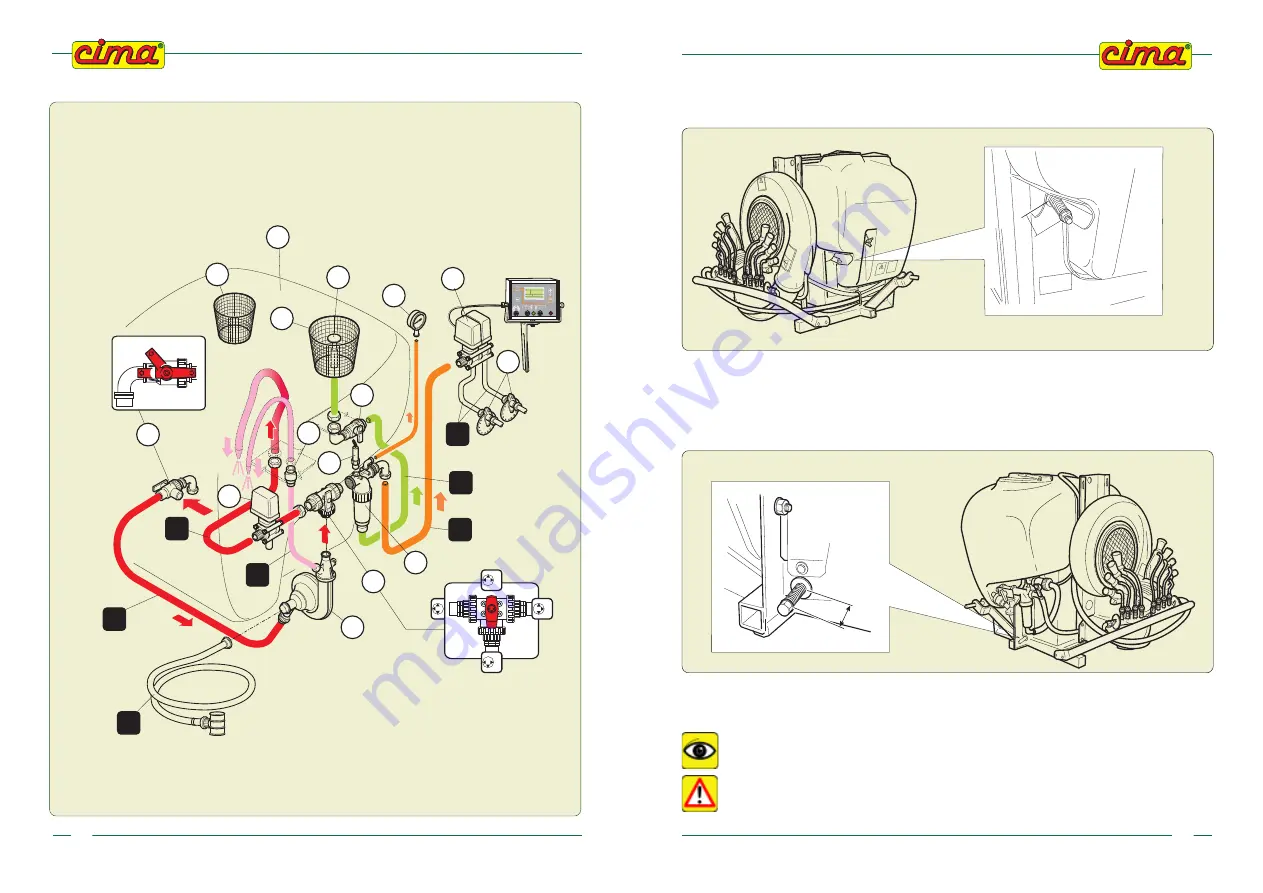

LEGEND:

P - E = elements of the circuit

T = piping

Hydraulic connections diagram

TANK

SUCTION

PIPE

FILLER PIPE

(ACCESSORY)

TO THE

DISTRIBUTION

HEAD

DUST

PRODUCTS

MIXER

00964

FILTER

AGITATION

PIPE

HYDRAULIC

AGITATION

MIXER

PIPE

DELIVERY

PIPE

PUMP

RETURN TO TANK

PIPE

09-2008

Plus 42 - 45 - 50 - 55

53

The belt setting will take place within the first 2 operating hours; when that time has elapsed, verify

the spring length, according with the time intervals (periodicity) indicated in the “Maintenance

operations’ table”.

13.8 - PUMP BELT TENSIONER

Check length “L” of the spring (refer to picture): it should be in tension between

4 and 5

cm.

If the value measured exceeds 5 cm, tighten the belt tightener screw, up to get the minimum length (4

cm).

00098

L

L = 9 ÷ 12 cm

00128

L

L = 4 ÷ 5 cm

00099

00298

13.9 - TANK REMOVAL OR REPLACEMENT

It is recommended to have the operation performed by a C.I.M.A. assistance point, such a

regulation is compulsory in case of REPLACEMENT of the tank.

The operation has to be carried out by complete absence of liquid residuals both

inside the tank and in the hydraulic circuit.