Plus 42 - 45 - 50 - 55

09-2008

18

P1. TANK

Tanks utilised:

polyethylene tanks of 300, 400 and 600 litre

capacity.

Each tank is made up of:

— tank main filler spout of 355 mm diameter, with

collapsible lid, breather and labyrinth seal, for

the filling with spraying products. Plastic cup-

like filter: 302 mm external diameter, height

254 mm with powder mixing device (for

versions in which this envisaged);

— supplementary tank filler with 250 mm diam-

eter screw-type lid, for filling with clear

water and plastic cup-like filter: external

diameter 204 mm, height 240 mm;

— transparent level indicator external pipe with

graduated scale;

— hydraulic agitation system connected to the

regulator (P5) and to the pump (P4).

— pneumatic agitation, connected to the piston

tap found above the tank and connected

through piping to the air intake located on the

fan casing.

A = OPEN

C = CLOSED

HYDRAULIC

AGITATION

“A”

“C”

HAND WASHING

TANK

PNEUMATIC

AGITATION

00075

00188

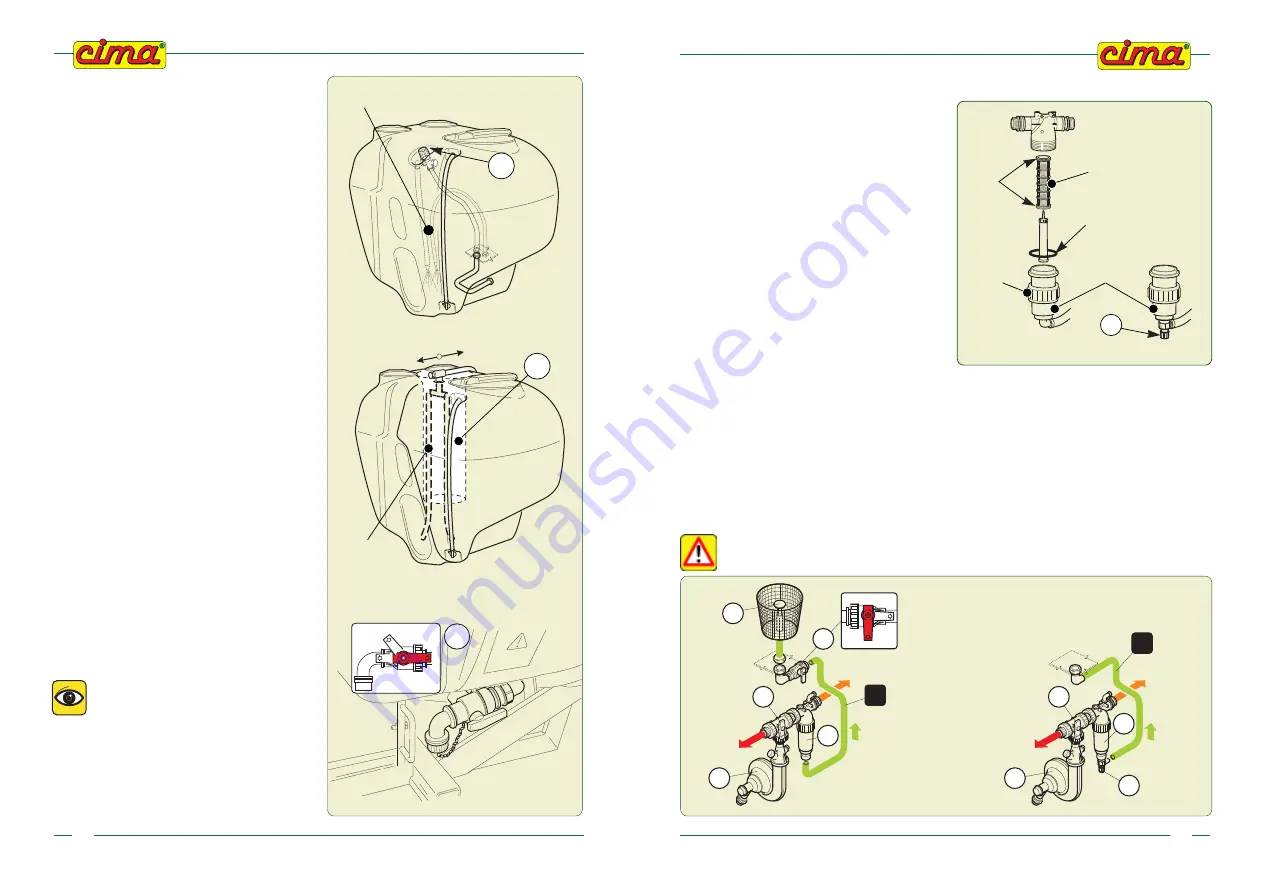

P2 - 3-WAY LEVER TAP A WITH

DISCHARGE FITTING

Fixed to tank (P1) and connected to the suction

piping (T1).

With the machine in operation the

tap’s lever must face towards the

suction piping (position “a”).

By positioning the lever towards

the drain plug (position “c”), total

draining of the tank is obtained.

In order to carry out the complete

discharge of any liquid remaining in

the pump and pipes, set the tap to

position “b”.

b

c

a

P2

00019

P22. HAND WASHING TANK

Incorporated polyethylene 17 litre capacity hand

wash tank, with external service tap; opening

though a 255 mm diameter screw lid.

P22

P5

09-2008

Plus 42 - 45 - 50 - 55

51

13.4 - CLEANING OF FILTER’S CARTRIDGE

7.

Reassemble the cartridge and secure the lid with the thumb screw.

Pay attention to the O-Ring

of the lower body during the assembly

: the incorrect sealing of the filter will jeopardise the

proper operation of the sprayer and cause loss of the mixture.

13.5 - PURGING OF RESIDUES FROM FILTER

With the machine in operation and the taps of the manual (P9) or electrical (E9) distributor closed.

Opening the powder mixer tap (P12) (or the self-cleaning filter faucet P25 -

for versions where it is

foreseen) the delivery flow will drag possible sludge to the bottom of the filter within the tank through

the piping (T6) thus partially cleaning the filtering cartridge. Close the tap when the operation is

completed.

When the machine is in operation, check that the drain tap (P12) (or P25) is closed

before opening the main feeder.

00306

FILTERING

CARTRIDGE

O.RING

O.RING

LOWER

BODY

OF FILTER

KNOB

1.

Set the lever of 3-way tap (P6) to the “d”

position

2

.

Completely close the pressure regulator, by

turning clockwise the handle of the manual

regulator (P5) or by turning the pressure up

(keep the joystick on “+” for about 15 secon-

ds) if the atomizer is provided with electric

regulator (E5).

3. Verify that the faucet (P12) of the powders

mixer (or the faucet of the self-cleaning filter

P25 - for the versions provided with) is

closed.

4.

Close the manual distributor’s taps (P9) or

position the switches of the control electric

switchboard (E10) on “OFF”

5. Undo the thumb screw and remove the body

of the filter.

6. Extract the cartridge: clean the grill and the

retaining O.Ring.

P25 *

* for versions where it is foreseen

P6

P4

P7

T6

P13

a

c

P12

P6

P4

P7

T6

P25

*

*

*

* for versions where it is foreseen

00975