9

STEP 10: Lifting the dust collector.

a. Position the dust collector on the floor, with the two

legs nearest the motor resting on the floor.

CAUTION: the dust collector can be raised

mechanically or manually. Because of the weight

of the dust collector, we strongly recommend

using a forklift, hoist or crane with guide ropes to

set the unit upright.

b.

IMPORTANT:

Attach a sling or cable, with at least

a 750 pound live load capacity, to the lifting eyes

on the blower side plate as shown in Fig. 14. Using

guide ropes, carefully raise the dust collector to an

upright position on the floor.

c. Without removing the lifting sling or cable and

keeping the sling or cable taut, carefully check the

alignment of the blower housing and feet. The blow-

er housing should be level with the feet adjusted to

the floor surface.

d.

IMPORTANT: Carefully loosen all the mounting

hardware for the three legs from the blower

housing down to the feet, including the leg

cross braces. After you have leveled the unit

with the floor surface, completely tighten all the

hardware at each location.

STEP 11: Installing the Vertical Dust Bag Support.

The vertical bag support

➄

is 2" x 2" x

1

⁄

8

" angle iron,

47

1

⁄

4

" long with 4 holes. Install it to the blower housing

mounting lug at the bottom of the blower discharge.

Attach with two 1

1

⁄

4

" long bolts, four flat washers, two

lock washers and two nuts as shown in Fig. 15. Make

sure this section is vertical, then tighten the nuts.

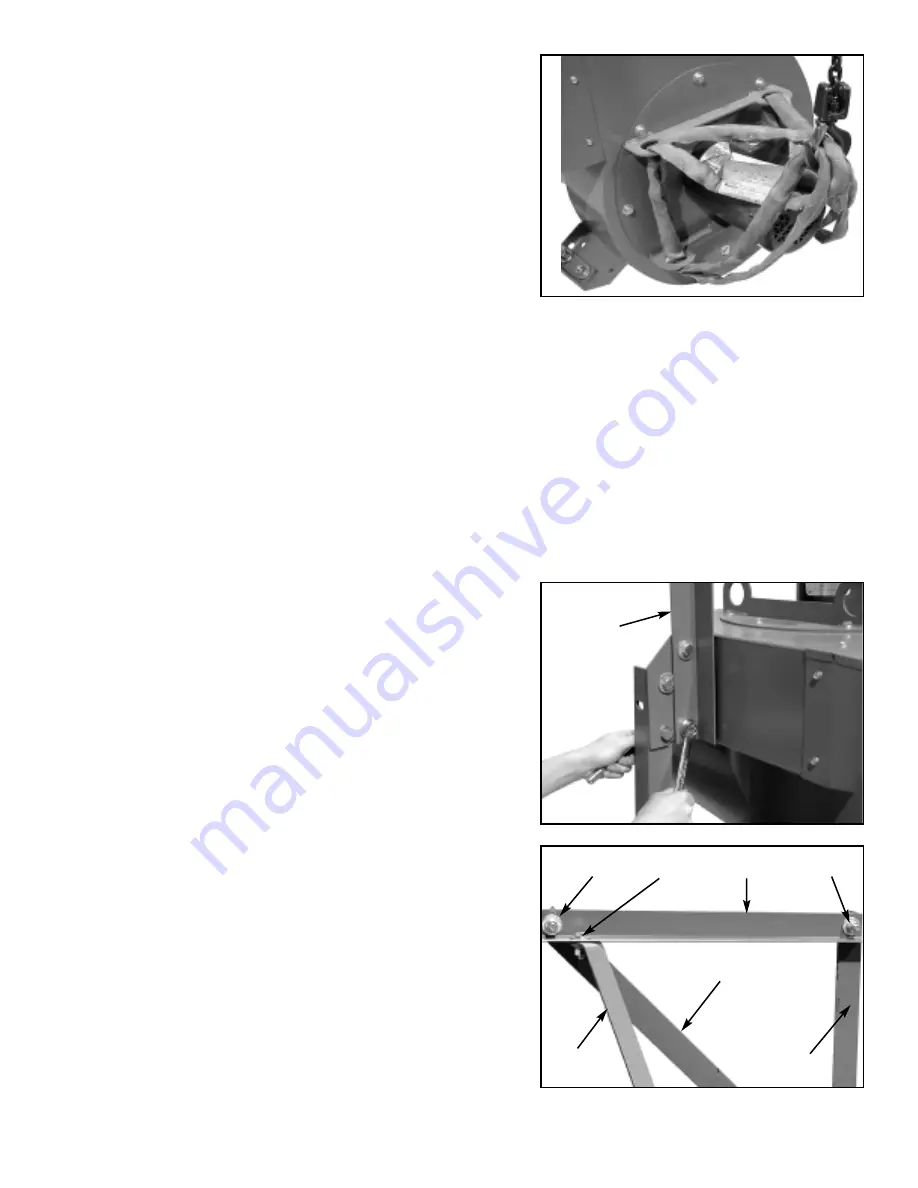

STEP 12: Installing other Bag Supports & Braces.

a. The horizontal bag support

➅

is 2" x 2" x

1

⁄

8

" angle iron,

47

1

⁄

4

" long with 5 holes and mitered at one end. Bolt the

square end with one hole to the vertical bag support

➄

with a

1

⁄

2

" x 1

1

⁄

4

" bolt, two flat washers, one lock washer

and one one nut at location EE in Fig. 16.

b. Bolt the 2" x 2" x

1

⁄

8

" angle cross brace

➆

to the vertical

support

➄

, using the round hole at the mitered end.

Use the same size hardware as step “

a

” above.

c. Bolt the other end to the horizontal bag support

➅

, at

location FF, with a

1

⁄

2

" x 1

1

⁄

4

" long bolt, two flat washers,

one lock washer and a nut.

▲

Fig. 14

▲

Fig.15

▲

Fig.16

WARNING:

DO NOT assemble any casters to the

feet, as they will affect the stability of

the dust collector and create a hazard.

After the dust collector is in its final

position, the holes provided in the feet

should be used to anchor the dust col-

lector to the floor.

➈

➆

➄

➄

➅

FF

GG

EE