ENGLISH

29

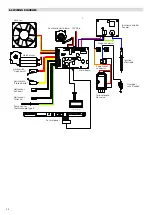

6.3 TECHNICAL ORIENTATION

6.2 APPLIANCE PROCESS OVERVIEW

The Cinderella appliance is designed according to fail-safe principles. In the event of component failure or

faulty control signals, the toilet will go into “safety mode”. This means that the unit will not be able to start an

incineration and error messages will appear on the display, ensuring that all component and/ or signal failures

that may occur are safeguarded in the system

The appliance is equipped with hall sensors that control both the lid and ash container. These sensors are

normally open and will be triggered when in contact with the magnet(s) mounted on the outside of the container

and inside the toilet lid.

When the lid is opened, the axial fan will start to ventilate the system. After each use, the incineration is activated

by pressing the button on the control panel. The bowl liner with its waste contents is dropped from the toilet

bowl into the incineration chamber, where it is safely incinerated at a high temperature.

The hatch mechanism is controlled by two microswitches, one mounted on the top of the toilet frame to check

that the hatch is in the desired “open” position, and one mounted on the lower front end of the appliance

ensuring that the hatch is in safe, enclosed position.

The gas system is controlled by an internal gas controller and is safeguarded with an advanced dual-solenoid

shut-off valve with an integrated pressure regulator. The ignition system is operated by the internal ignition

controller and the ignition electrode functions both as an igniter and flame fault. The ignition electrode will

monitor the flame and safeguard any disturbances or deviations inside the burner.

During incineration, the air supplied into the room provides the oxygen required for proper Incineration. The

exhaust vent removes excess heat. All fumes and vapours are processed through a heat-activated platinum

catalyst to reduce emissions and odours.

The temperature inside the incineration chamber is closely monitored by the thermocouple mounted inside the

chamber, the temperature inside the toilet is safeguarded by the bimetal thermostat mounted on the interior

frame of the toilet.

The incineration process can take 40 – 180 minutes and is controlled automatically by the appliance’s sensory

technology. The toilet can be used at any time while incinerating. The incinerating process will be paused when

the lid is opened and automatically reactivated when lid is closed. Numerous safeguards exist to ensure safe

operation. See section 3.5 of this manual.

Liner placed in bowl

Ash container

Outlet air

Axial fan

Burner tube

Catalytic converter

Inlet air

Hall sensor

Thermocouple

1

2

3

4

5

6

7

8

9

ID

PART DESCRIPTION

1

Axial fan

2

Liner placed in bowl

3

Burner tube

4

Ash container

5

Hall sensor

6

Thermocouple

7

Inlet air

8

Catalytic converter

9

Outlet air

Summary of Contents for FREEDOM GAS NA

Page 62: ...32...

Page 63: ...FRAN AIS 33...