Throttle Trim Function

The throttle trim allows you to fine-tune the position of the throttle servo or speed controller so as to give correct

throttle response. When you first switch ‘ON’ your transmitter and model (and start the engine in the case of an engine

powered model), the drive wheels on the model should not be turning. This is the neutral position. If the drive wheels

are turning (either forwards or reverse), you can adjust the throttle trim to stop them and bring your model back to

neutral. Throttle servo trimming is best done with the model’s drive wheels off the ground to ensure that you do not

have a runaway model whilst your are adjusting the trim.

You adjust the throttle trim using the ‘DT2’ button located at the left side of the steering wheel.

Push the ‘DT2’ button up or down to trim the throttle servo so that the model’s wheels are not turning. Pulling the

transmitter’s trigger should give almost immediate acceleration and pushing the trigger forward should give almost

immediate reverse (electric) or brake (nitro/engine) operation. You can fine-tune the trim to set this correctly. Note,

some electric models are fitted with electronic speed controllers that have a dual brake/reverse function. In this case,

it may be necessary to push the trigger several times to operate reverse.

Note 1: If by adjusting the throttle trim the model’s wheels begin to turn faster, you are adjusting the wrong

way. In this case, simply adjust in the opposite direction until the wheels stop turning.

Note 2 : If you need to adjust the trim to a too large a degree, it may be that you need to re-set/re-centre the

servo output arm’s position on top of the servo and trim again as necessary. When doing this, be sure to

have both the transmitter and receiver switched ‘ON’, and to set the servo’s trim on the transmitter back to

0%, before re-attaching the servo arm so that the servo is returned to its actual neutral position.

Description of Functions

If a servo operates in the opposite direction to that required, e.g., turning the transmitter’s steering wheel left causes

the model to steer right, or pulling the trigger for forward movement causes the model to travel in reverse or applies

the brake, you can correct the servo’s movement with the appropriate reverser.

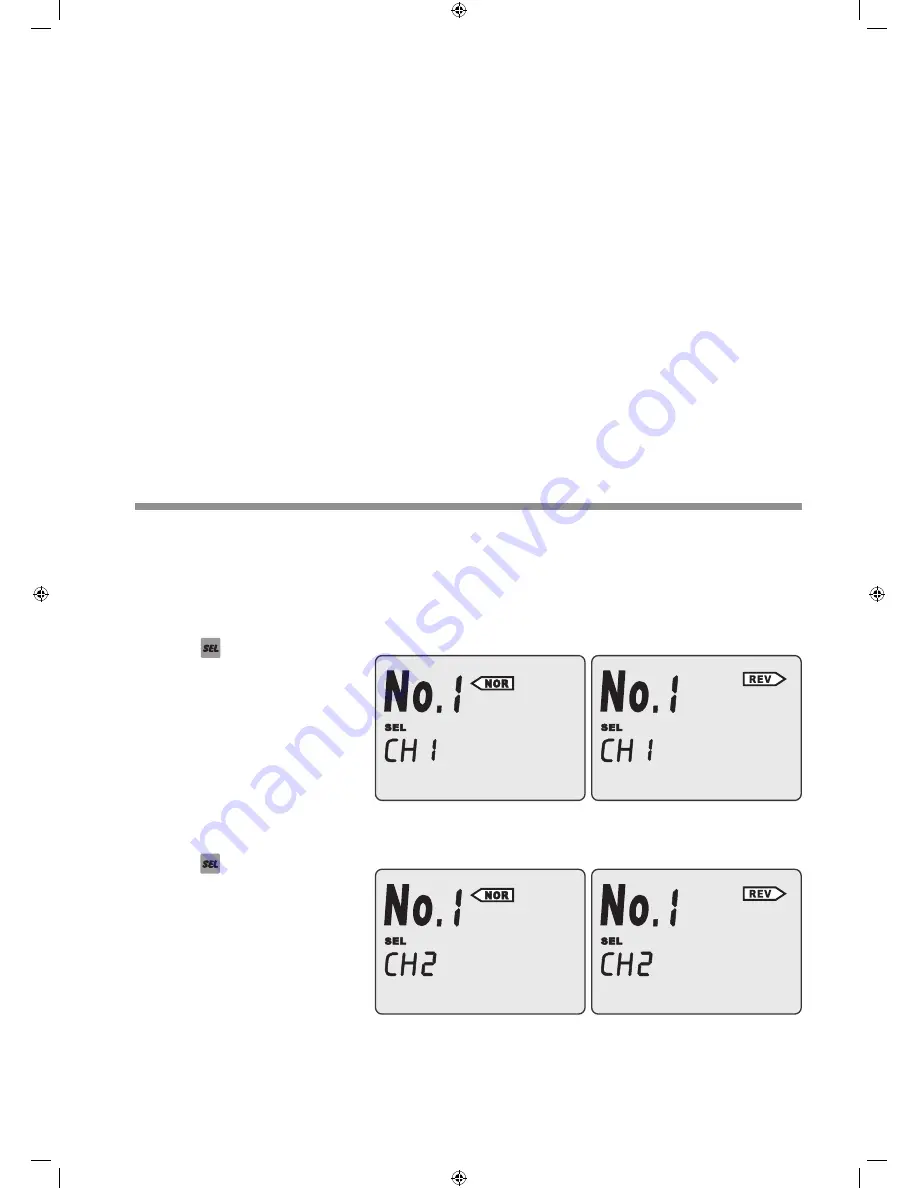

Servo Reversing on CH1 (Steering)

Press the

button once in normal

display mode to enter the Servo

Reversing setting menu for Channel 1.

Push the ‘DT1’ button either left or right

to set a normal (NOR) or reversed (REV)

control state.

Note: The default state is normal

(NOR) state.

Servo Reversing on CH2 (Throttle & Reverse/Brake)

Press the

button twice in normal

display mode to enter the Servo

Reversing setting menu for Channel 2.

As for Ch1 adjustment above, push the

‘DT1’ button either left or right to set a

normal (NOR) or reversed (REV) control

state.

Note: The default state is normal

(NOR) state.

6