51-20

Page 20

All

EFFECTIVITY:

C I R R U S

A I R P L A N E M A I N T E N A N C E M A N U A L

M O D E L S R 2 0

01 Jan 2012

Note:

The adhesive bead should have a high point near the center of the bead to

avoid entrapped air. When more than one bead is required, apply immedi-

ately adjacent to the prior bead to form one large bead.

(g)

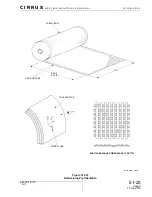

Apply a bead of adhesive down the center of the bond width, approximately 0.13 - 0.25

inch (3.18 - 6.35 mm) bead for each 1.0 inch (25.4 mm) of bond width.

Note:

Avoid applying, removing, and re-applying clamping pressure, as this will

cause air to become entrapped in the bond gap.

(h)

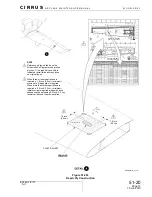

Secure parts in bond fixture, ensuring that pressure is applied uniformly.

(i)

Check edge of bondline for excess adhesive. Remove excess adhesive with cloth damp-

ened with isopropyl alcohol.

(j)

Cure bond.

(3)

PTM&W ES6292-Based Structural Adhesive Application

Application of structural adhesive is required for secondary bond repairs where the technician

must bond two pre-cured components together.

CAUTION:

PTM&W ES6292, when allowed to sit creates amine blush. This surface layer

inhibits proper bonding and care must be taken to avoid it.

Proper application of PTM&W ES6292 adhesive is critical to obtaining full bond

strength. Application procedures differ from other structural adhesive applications

and should be fully understood before mixing.

Note:

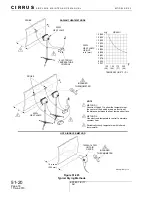

Nominal bondline thickness for structural repair is 0.060 +0.020/-0.055 inch

(0.152 +0.051/-0.140 cm) unless otherwise noted.

(a)

Acquire necessary tools, equipment, and supplies.

(b)

Prepare repair surface as necessary.

(c)

Pre-fit faying surfaces of parts to ensure the bond fixture used will bring the bonded sur-

faces into an allowable tolerance during adhesive curing.

Note:

PTM&W ES6292 A/B Paste Adhesive has a pot-life at 68

o

F of 45 minutes.

High ambient temperatures will shorten pot-life. An 18

o

F increase will cut

pot-life to 22 minutes. Relative humidity above 65% accelerates reaction

and also shortens pot-life. Working-life of 35 minutes is similarly affected.

(d)

Mix structural adhesive.

(e)

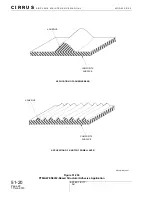

On first surface of the repair, apply adhesive using one of the following methods.

Description

P/N or Spec.

Supplier

Purpose

Trowel, 1/4” V-notch

-

Any Source

Spread adhesive.

Cartridge or Extrusion Gun -

Any Source

Apply adhesive.

Bond Fixture (as necessary) -

Any Source

Bonding.

Clamps (as necessary)

-

Any Source

Bonding.

PTM&W ES6292-Based

Structural Adhesive

Bond Repairs.