79-30

Page 8

Serials 1602, 1644, 1663 & subs

EFFECTIVITY:

C I R R U S

A I R P L A N E M A I N T E N A N C E M A N U A L

M O D E L S R 2 2

15 Apr 2007

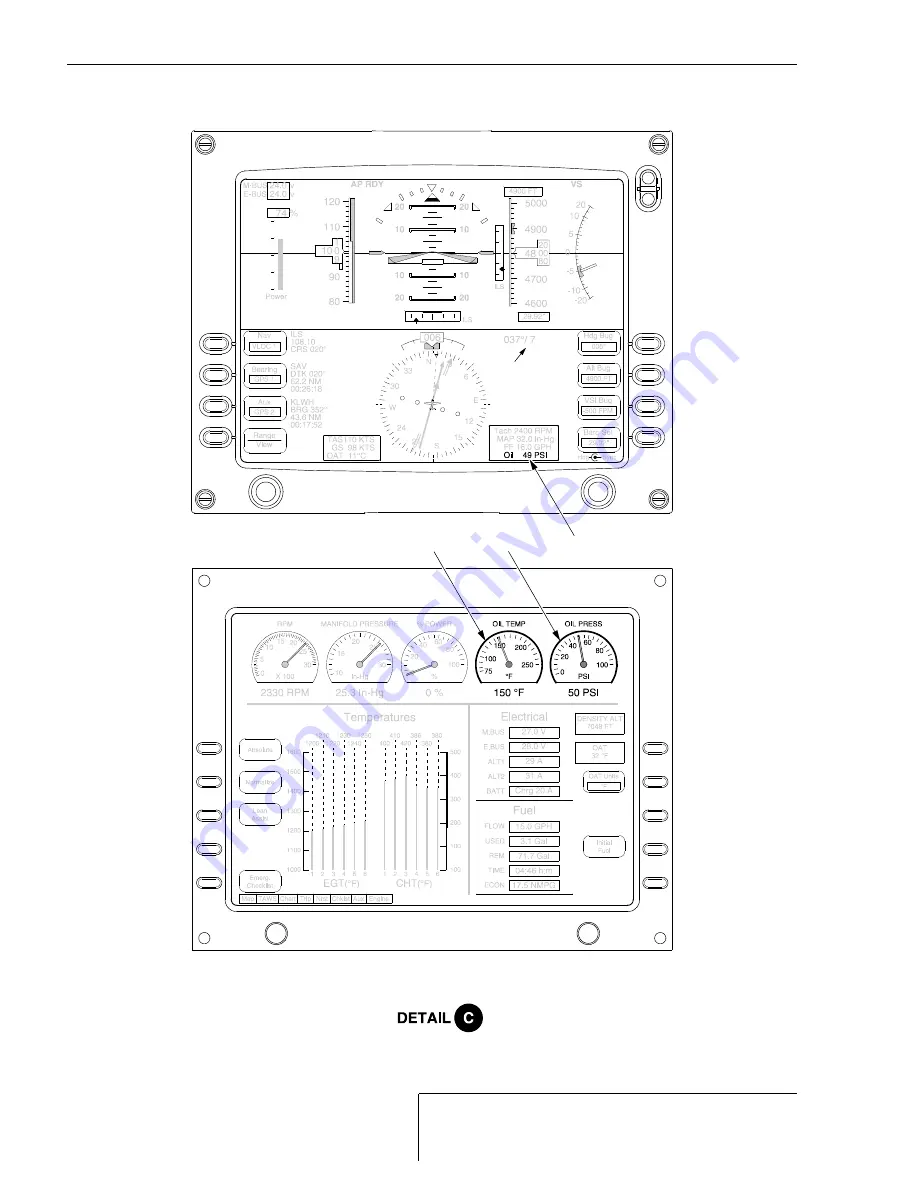

Figure 79-301

Oil Pressure and Oil Temperature Indication - Serials 1602, 1644, 1663 & subs (Sheet 2 of 2)

SR22_MM79_2232

LEGEND

1. Oil Pressure Gage

2. Oil Temperature Gage

1,2

2

1