32

Cisco 6100 Thermal Upgrade Kit Installation Procedures

78-10158-01

Installing the Cisco 6100 Thermal Upgrade Kit

Attach Fan Tray Power Connections for a Dual-Power Feed

To attach the fan tray power connections to the fuse and alarm panel for a dual-power feed, complete

the following steps:

Step 1

Use a socket driver or a Phillips-head screwdriver to remove the clear cover over the fan tray

power connections.

Step 2

Measure enough wire (14 to 18 AWG copper solid or stranded wire) to connect each of the fan tray

power connections to the fuse and alarm panel.

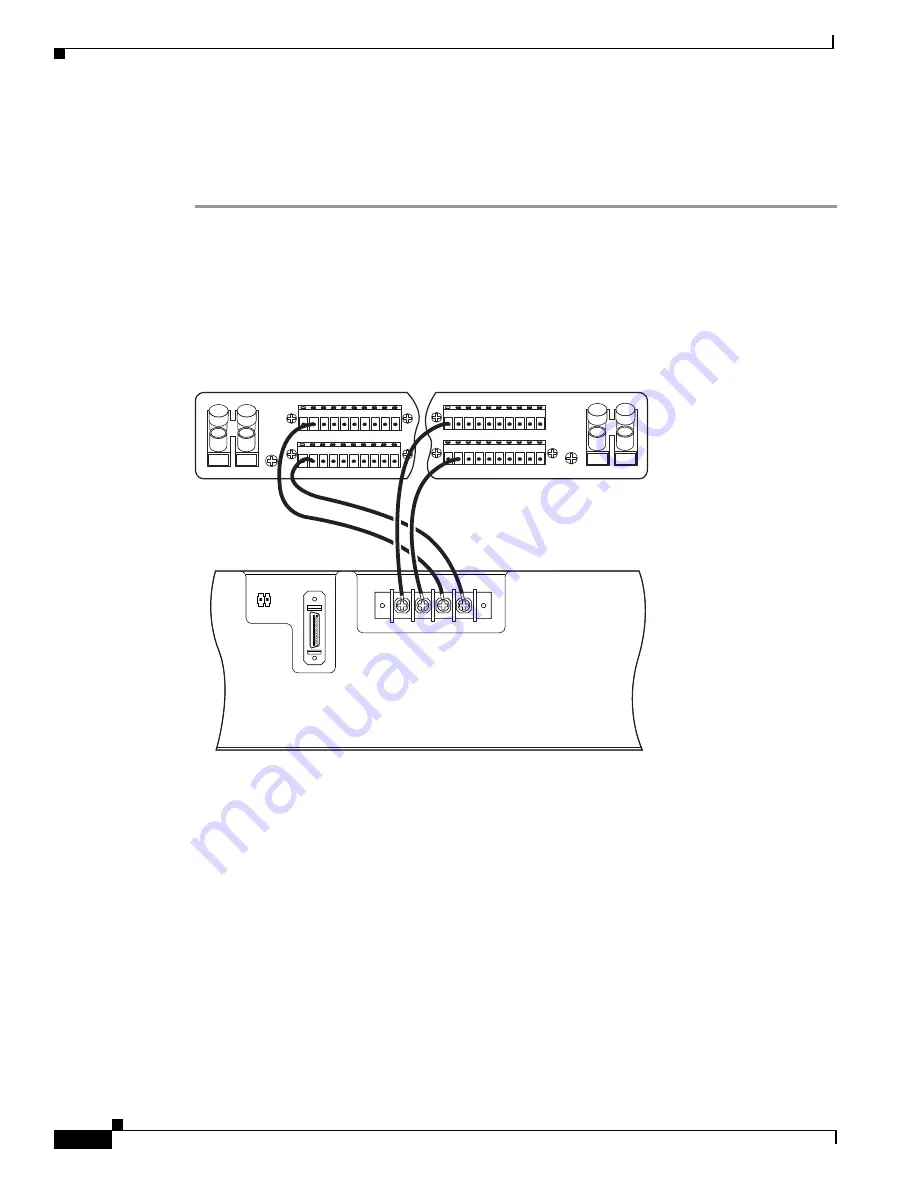

Figure 17 shows the power connections from the fan tray to the fuse and alarm panel for a

dual-power feed.

Figure 17

Power Connections for the Fan Tray—Dual-Power Feed

Step 3

Use a wire stripper to remove the casing from both ends of the wires.

Step 4

Use a Phillips-head screwdriver to attach a wire to the –48VA power input connection on the fan

tray (P1).

Step 5

Attach the wire to the fuse and alarm panel NEG DC connector. See Figure 17 for correct placement.

Step 6

Use a Phillips-head screwdriver to attach a wire to the –48VB power input connection on the fan

tray (P1).

Step 7

Attach the wire to the fuse and alarm panel NEG DC connector. See Figure 17 for correct placement.

Step 8

Use a Phillips-head screwdriver to attach a wire to a –48RTN power return connection on the fan

tray (P13).

Step 9

Attach the wire to a fuse and alarm panel POS RTN connector.

1 2 3 4 5 6 7 8 9 10

NEG

NEG

POS

POS

NEG DC

NEG DC

POS RTN

POS RTN

B

A

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8 9 10

26376

P2

J1

P1

FAN

P2

J1

-48VB

RT

N

-48V

A

RT

N

+

_

-48V

RTN -48V

RTN

Fan tray