2-14

Cisco 7500 Series Installation and Configuration Guide

OL-5008-03 B0

Chapter 2 Preparing for Installation

Site Environment, Chassis Temperature, and Airflow Guidelines

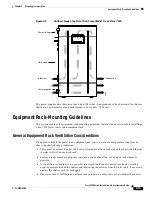

Cisco 7507 and Cisco 7507-MX Airflow Considerations

The system blower on the Cisco 7507 and Cisco 7507-MX provides cooling air for the processor

modules. The blower draws air in through the air filter in the front chassis panel and directs it up through

the floor of the internal slot compartment and over the cards. The exhaust air is forced out the rear of the

chassis above and to each side of the processor slots. The blower needs a clean air filter in order to draw

in sufficient amounts of cooling air; excessive dust in the filter will restrict the airflow. Keep the air filter

clean and replace it when necessary.

Figure 2-8

shows the system blower and airflow through the Cisco 7507 and Cisco 7507-MX.

Figure 2-8

Airflow Through the Cisco 7507 and Cisco 7507-MX

Sensors on the RSP2 (for example) monitor the inlet and internal chassis air temperatures. If the air

temperature at either of the sensors exceeds a desired threshold, an environmental monitor displays

warning messages and can interrupt system operation to protect the system components from possible

damage from excessive heat or electrical current.

The power supplies have their own fans. An air dam between the power supply bays and the processor

module compartment keeps the airflow constant.

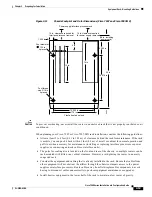

Cisco 7513, Cisco 7513-MX, and Cisco 7576 Airflow Considerations

The blower on the Cisco 7513, Cisco 7513-MX, and Cisco 7576 provides cooling air for the processor

modules. The exhaust air is forced out the front of the chassis behind the card cage.

Figure 2-9

shows the system blower and airflow through the Cisco 7513, Cisco 7513-MX, and Cisco

7576.

H3882

Power

supplies

Front of

chassis

Rear of

chassis

Air dam

6

Air dam

System

blower

5

4

3 (RSP2)

2 (RSP2)

1

0

Top view of router