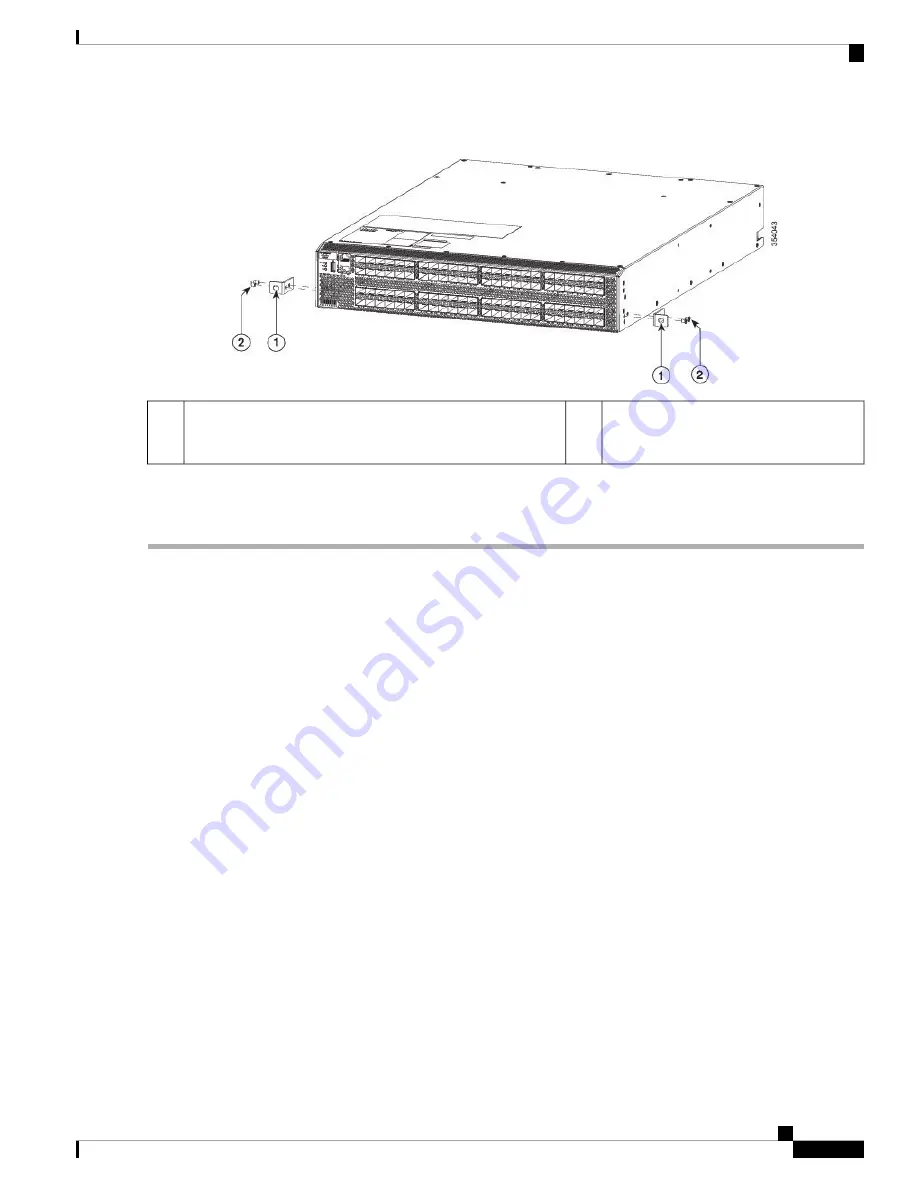

Figure 1: Aligning and Attaching Front-Mount Brackets to the Sides of the Chassis

Two M4 x 6 mm screws used to fasten the

bracket to the chassis.

2

Front-mount bracket with two screw holes aligned to two screw

holes in the chassis and one screw hole facing the port side of

the chassis.

1

Step 2

Use two M4 x 6 mm screws to attach the bracket to the chassis. Tighten each screw to 11 to 15 in-lb (1.2 to1.7 N·m).

Step 3

Repeat Steps 1 and 2 to attach the second front-mount bracket to the other side of the chassis.

What to do next

You are ready to mount the chassis to the four-post rack.

Installing the Switch

Before you begin

• You need to slide the chassis onto the bottom-support rails so that the end with the fan trays and power

supplies locks onto the chassis stops at the end of the rails and so that the front-mount brackets on the

chassis come into contact with the front-mount rails on the rack.

• Make sure that the four-post rack is properly installed and secured to the concrete floor.

• Make sure that the bottom-support rails are installed so that the power supplies and fan trays will be in

the appropriate aisle.

• The color of the stripe on fan trays and the color of the latch on power supplies determines which end

of the switch must be positioned in the cold aisle as follows:

• If the modules have burgundy coloring, position the port end of the chassis in the cold aisle.

• If the modules have blue coloring, position the fan trays and power supply end of the chassis in the

cold aisle.

• Make sure that two front-mount brackets are securely fastened to the sides of the chassis at the port end.

Installing the Cisco MDS 9396S Switch

7

Installing the Cisco MDS 9396S Switch

Installing the Switch