Figure 48: Inserting QSFP Pluggable (1.2T Line Card)

The pull tabs of the pluggables must always face down for top rows; the pull tabs of the pluggables must always

face up for bottom rows.

Caution

Do not forcibly push the pluggable into the slot, this might damage the pluggable and/or the slot.

Step 3

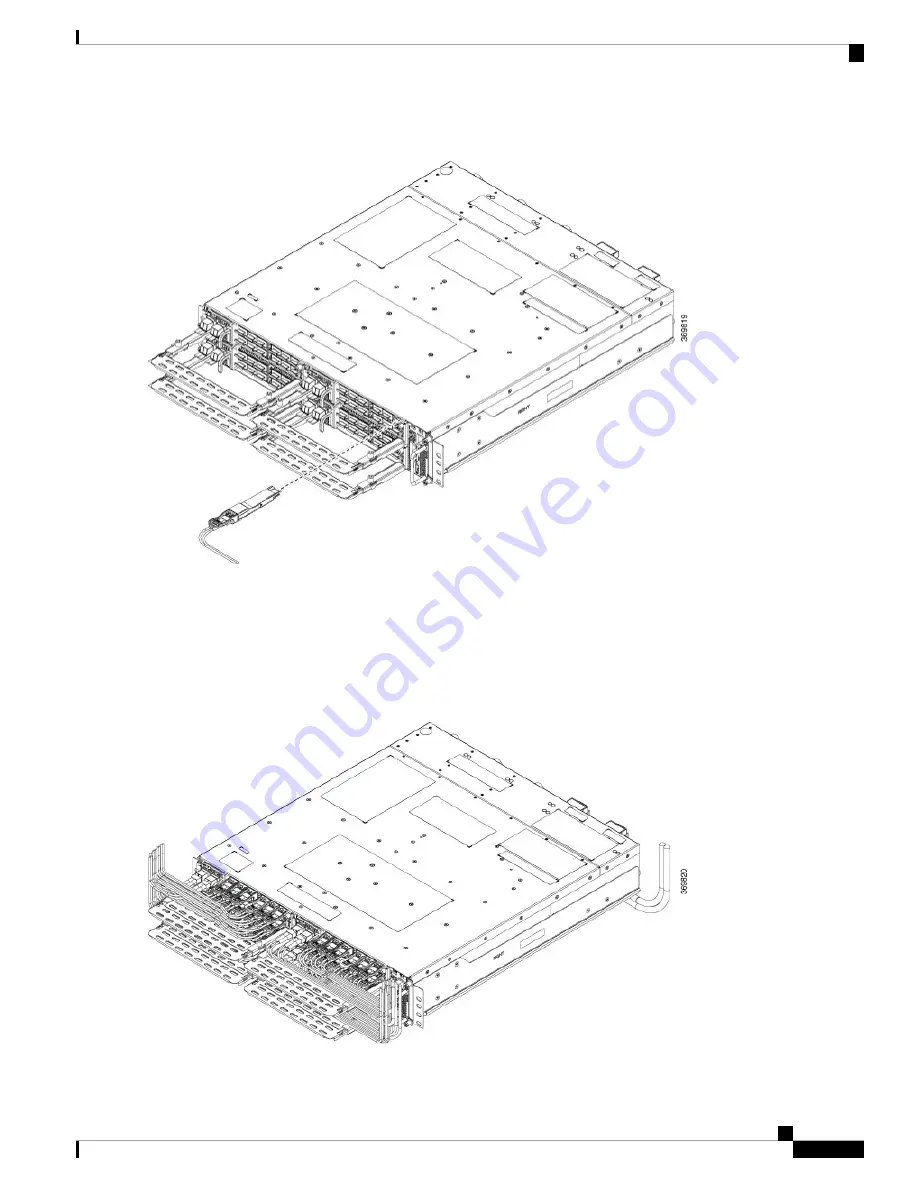

Route the cables emerging from the pluggables using the fiber management bracket as shown in the following figure.

Figure 49: Fiber Management Bracket with fibers from Pluggables (1.2T Line Card)

Hardware Installation Guide for Cisco NCS 1004

51

Install Cisco NCS 1004 Modules

Install Pluggables