5-17

Cisco Network Convergence System 4000 Series Hardware Installation Guide

Chapter 5 Installing Route Processor Cards, Fabric Cards, and Line Cards

About Line Cards

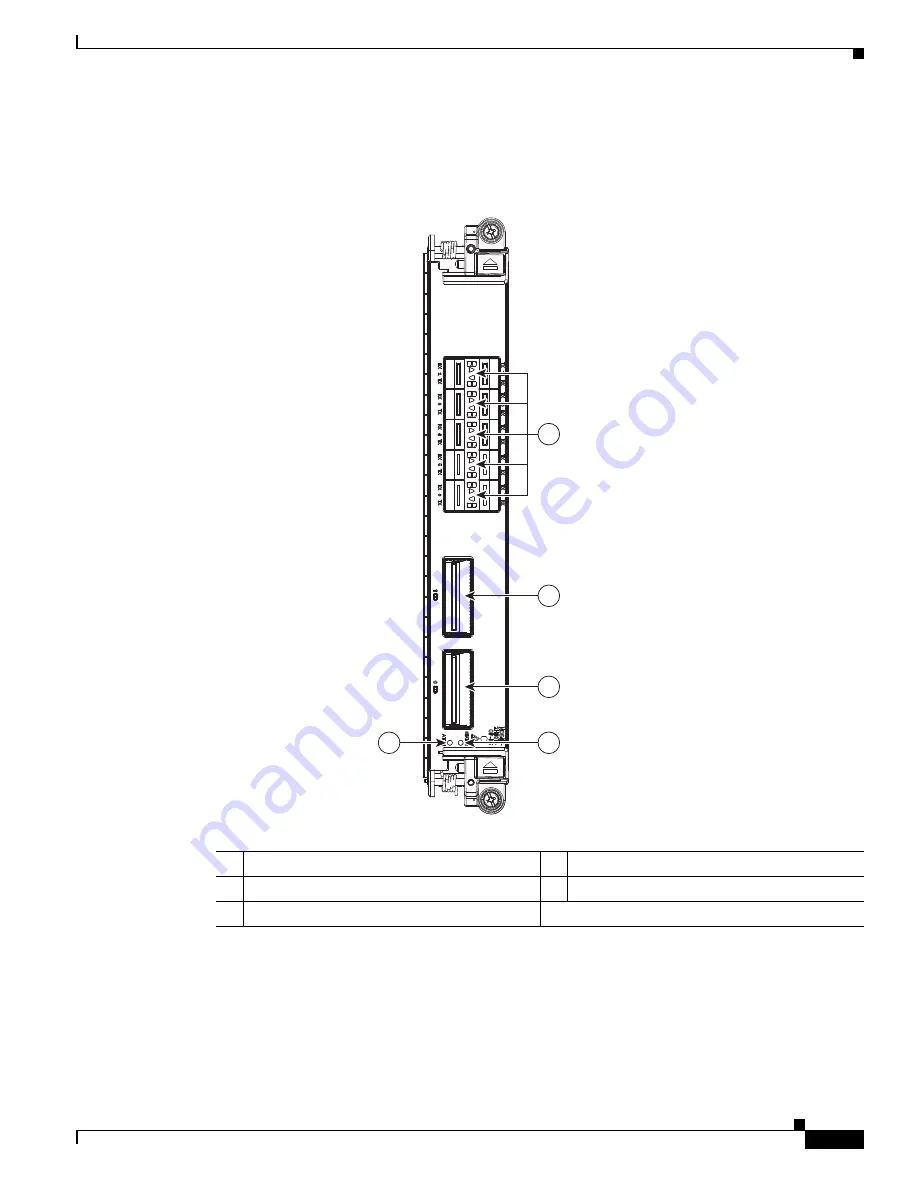

shows the details of the front panel of the 2-port 100Gbps and 10-port 10 Gbps OTN and

packet line card.

Figure 5-7

Front Panel of the 2-Port 100 Gbps and 10-Port 10 Gbps OTN and Packet Line Card

1. Port LEDs are triangular in shape and point toward the port that they support.

4

3

2

5

363614

1

1

Port LEDs (one LED on each port)

1

2

CPAK 1 port

3

CPAK 0 port

4

Status LED

5

Attention LED