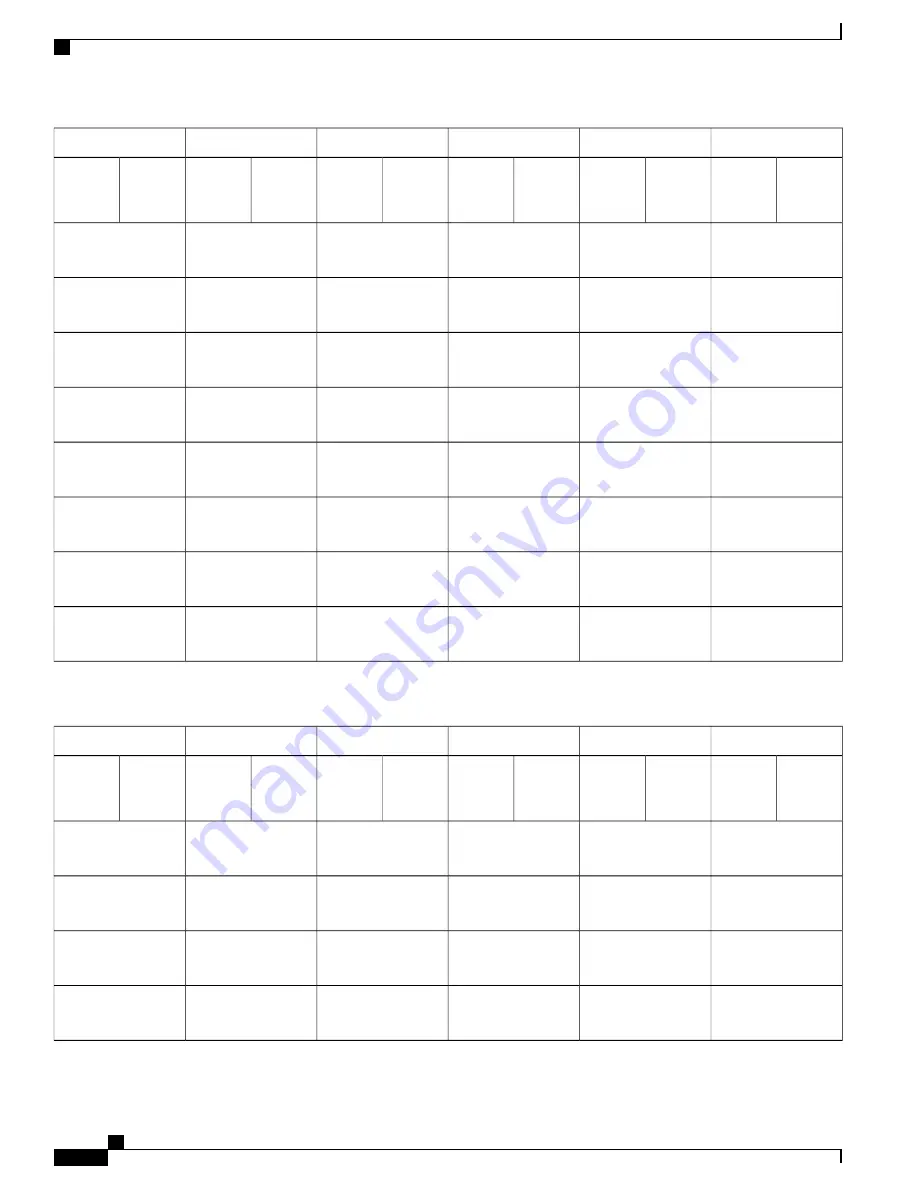

Plane 5

Plane 4

Plane 3

Plane 2

Plane 1

Plane 0

FCC (S2)

slot/port/

chassis

LCC1

(S13)

slot/port

FCC (S2)

slot/port/

chassis

LCC1

(S13)

slot/port

FCC (S2)

slot/port/

chassis

LCC1(S13)

slot/port

FCC (S2)

slot/port/

chassis

LCC1

(S13)

slot/port

FCC (S2)

slot/port/

chassis

LCC1

(S13)

slot/port

FCC (S2)

slot/port/

chassis

LCC1

(S13)

slot/port

S5/8 to FC5/8

(FCC1)

S4/8 to FC4/8

(FCC1)

S3/8 to FC3/8

(FCC1)

S2/8 to FC2/8

(FCC1)

S1/8 to FC1/8

(FCC1)

S0/8 to FC0/8

(FCC1)

S5/9 to FC5/9

(FCC1)

S4/9 to FC4/9

(FCC1)

S3/9 to FC3/9

(FCC1)

S2/9 to

FC2/9(FCC1)

S1/9 to FC1/9

(FCC1)

S0/9 to FC0/9

(FCC1)

S5/10 to FC5/10

(FCC1)

S4/10 to FC4/10

(FCC1)

S3/10 to FC3/10

(FCC1)

S2/10 to FC2/10

(FCC1)

S1/10 to FC1/10

(FCC1)

S0/10 to FC0/10

(FCC1)

S5/11 to FC5/11

(FCC1)

S4/11 to FC4/11

(FCC1)

S3/11 to FC3/11

(FCC1)

S2/11 to FC2/11

(FCC1)

S1/11 to FC1/11

(FCC1)

S0/11 to FC0/11

(FCC1)

S5/12 to FC5/12

(FCC1)

S4/12 to FC4/12

(FCC1)

S3/12 to FC3/12

(FCC1)

S2/12 to FC2/12

(FCC1)

S1/12 to

FC1/12(FCC1)

S0/12 to FC0/12

(FCC1)

S5/13 to FC5/13

(FCC1)

S4/13 to FC4/13

(FCC1)

S3/13 to FC3/13

(FCC1)

S2/13 to FC2/13

(FCC1)

S1/13 to FC1/13

(FCC1)

S0/13 to FC0/13

(FCC1)

S5/14 to FC5/14

(FCC1)

S4/14 to FC4/14

(FCC1)

S3/14 to FC3/14

(FCC1)

S2/14 to FC2/14

(FCC1)

S1/14 to FC1/14

(FCC1)

S0/14 to FC0/14

(FCC1)

S5/15 to FC5/15

(FCC1)

S4/15 to FC4/15

(FCC1)

S3/15 to FC3/15

(FCC1)

S2/15 to FC2/15

(FCC1)

S1/15 to FC1/15

(FCC1)

S0/15 to FC0/15

(FCC1)

Table 36: Cabling Plan for LCC2 in a 4+2 Multi-Chassis Configuration with 12 S2 Fabric Cards

Plane 5

Plane 4

Plane 3

Plane 2

Plane 1

Plane 0

FCC (S2)

slot/port/

chassis

LCC2

(S13)

slot/port

FCC (S2)

slot/port/

chassis

LCC2

(S13)

slot/port

FCC (S2)

slot/port/

chassis

LCC2

(S13)

slot/port

FCC (S2)

slot/port/

chassis

LCC2

(S13)

slot/port

FCC (S2)

slot/port/

chassis

LCC2

(S13)

slot/port

FCC (S2)

slot/port/

chassis

LCC2

(S13)

slot/port

S5/0 to FC5/16

(FCC0)

S4/0 to FC4/16

(FCC0)

S3/0 to FC3/16

(FCC0)

S2/0 to FC2/16

(FCC0)

S1/0 to FC1/16

(FCC0)

S0/0 to FC0/16

(FCCO)

S5/1 to FC5/17

(FCC0)

S4/1 to FC4/17

(FCC0)

S3/1 to FC3/17

(FCC0)

S2/1 to FC2/17

(FCC0)

S1/1 to FC1/17

(FCC0)

S0/1 to FC0/17

(FCC0)

S5/2 to FC5/18

(FCC0)

S4/2 to FC4/18

(FCC0)

S3/2 to FC3/18

(FCC0)

S2/2 to FC2/18

(FCC0)

S1/2 to FC1/18

(FCC0)

S0/2 to FC0/18

(FCC0)

S5/3 to FC5/19

(FCC0)

S4/3 to FC4/19

(FCC0)

S3/3 to FC3/19

(FCC0)

S2/3 to FC2/19

(FCC0)

S1/3 to FC1/19

(FCC0)

S0/3 to FC0/19

(FCC0)

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

178

Cabling a Multi-Chassis Configuration

Multi-Chassis 4+2 Configuration