Receiver Description

78-4015908-01 Rev F

5

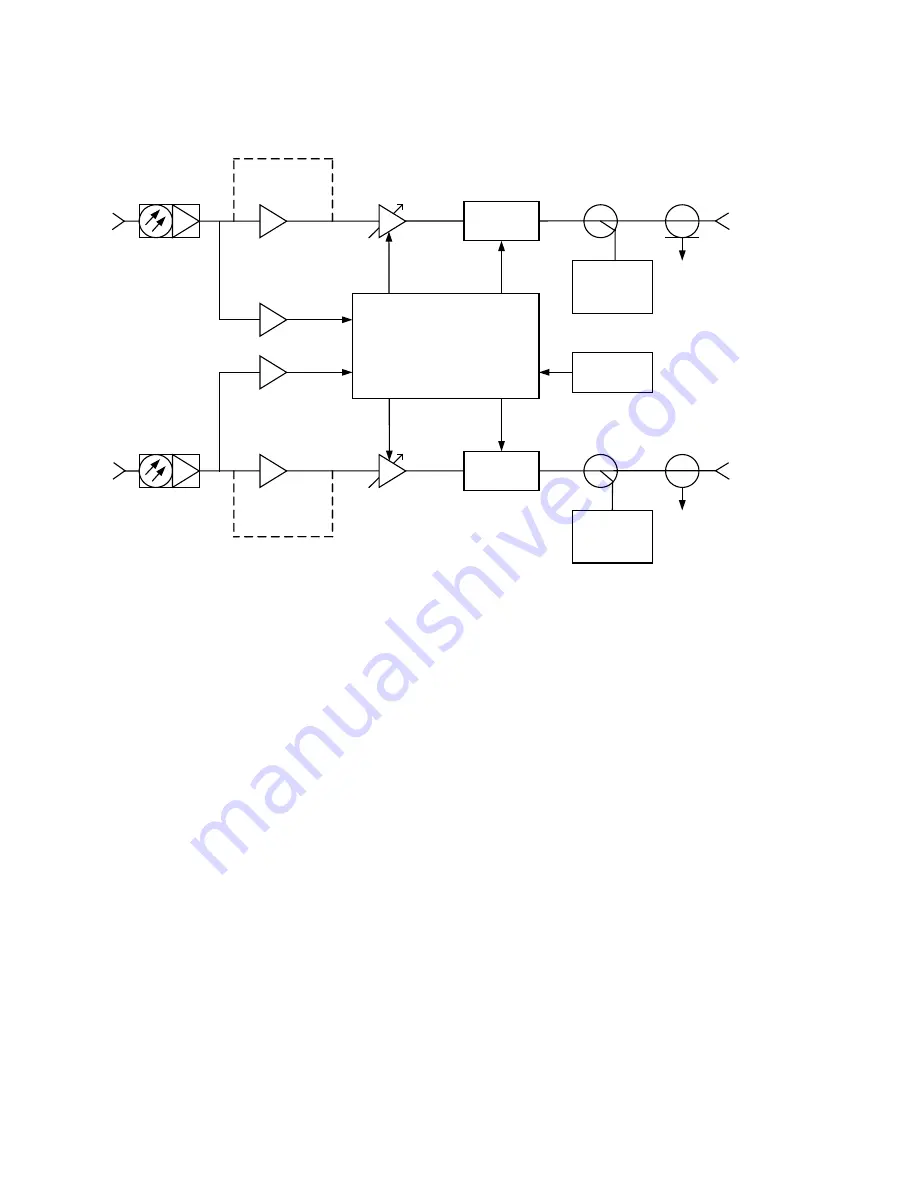

Receiver Block Diagram

Temperature

Sensor

High Gain

RF Amp

Front Panel

Test Point

-20 dB

Optical Power

Monitor

-20 dB Directional

Coupler

Termination

Switch

RF

Output

1

TP515

Optical

Input 1

Variable Gain

RF Amp

Optical Power

Monitor

RF

Output

2

Optical

Input 2

Termination

Switch

Front Panel

Test Point

-20 dB

High Gain

RF Amp

-20 dB Directional

Coupler

Variable Gain

RF Amp

Client Control Board (CCB)

Standard Gain Bypass

Standard Gain Bypass