• Cisco preconfigured racks have not been certified for air transport.

• The preracked Cisco UCS system must ship in an upright position.

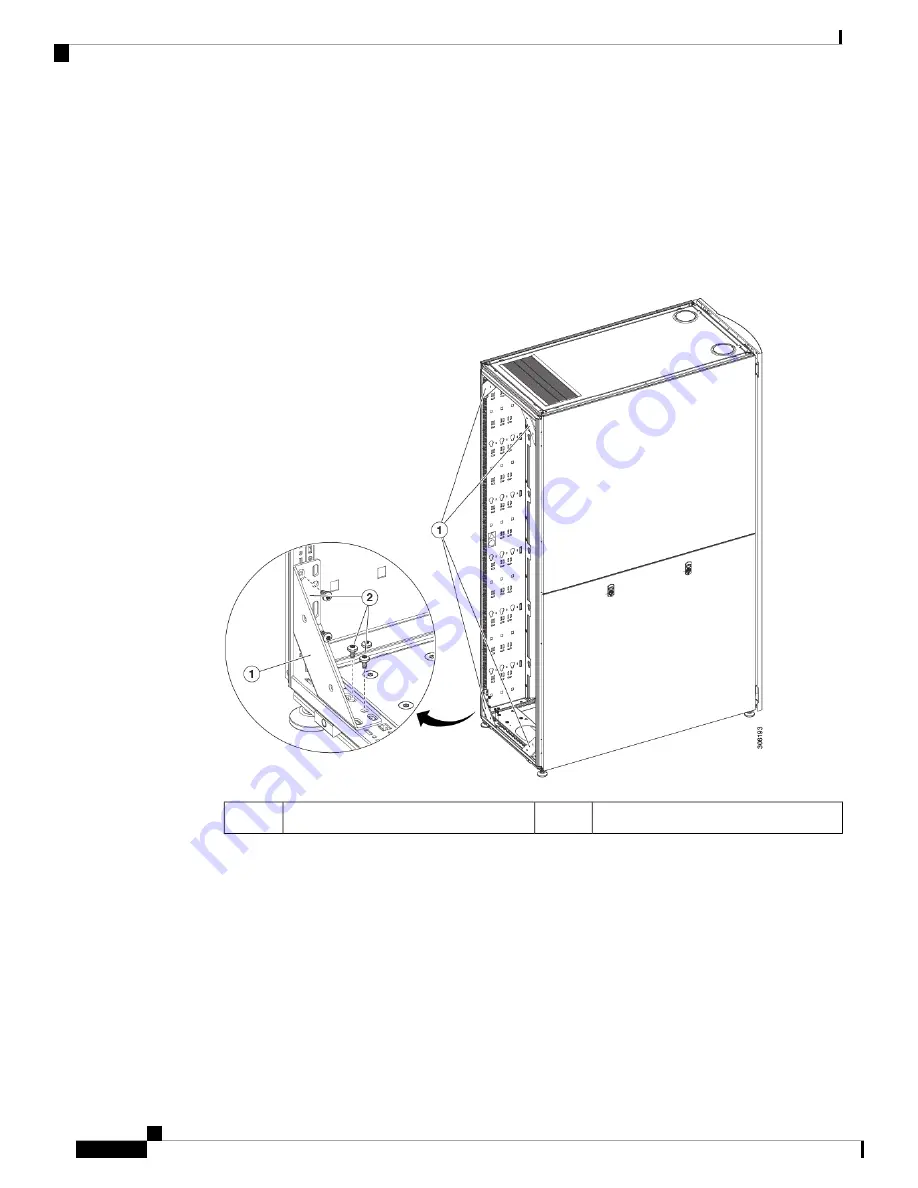

• Angle brackets should be installed in the corners of the rack to ensure that the equipment is secure and

does not move during transport. See the following illustration to see the locations of the brackets and the

screws required to install them. These brackets should be removed when the rack reaches its final

destination.

Figure 41: Installing and Removing Rear Corner Angle Brackets

Screws that hold the bracket in place.

2

Bracket installed in the corner of the rack.

1

• UCS components may be damaged if the rack tips over during shipment. To avoid such damage, secure

the racks by strapping them down in the truck. Strapping the rack will help prevent it from tipping over

during transport to the customer site.

• On a Cisco R-Series rack, check to ensure that the rack mounting brackets are properly secured to the

pallet. The bracket with keyhole cutouts should be at an angle to the pallet deck and should not be loose.

The front hold-downs for Cisco R-Series rack are right-angled and sit flush to the pallet and frame. Ensure

that the bolt that secures the bracket to the frame is torqued to 70-100 in-lb. (6-9 N-m).

• Prepare the rack for shipment by attaching the packaging shown in the following illustration.

Cisco R42612 Rack and RP-Series Metered Input PDU Installation Guide

84

Integrating UCS Components in the Dynamic Rack

Integrating UCS Components in the Dynamic Rack