Chapter 2 Installing the Tap

24

4013399 Rev C

5

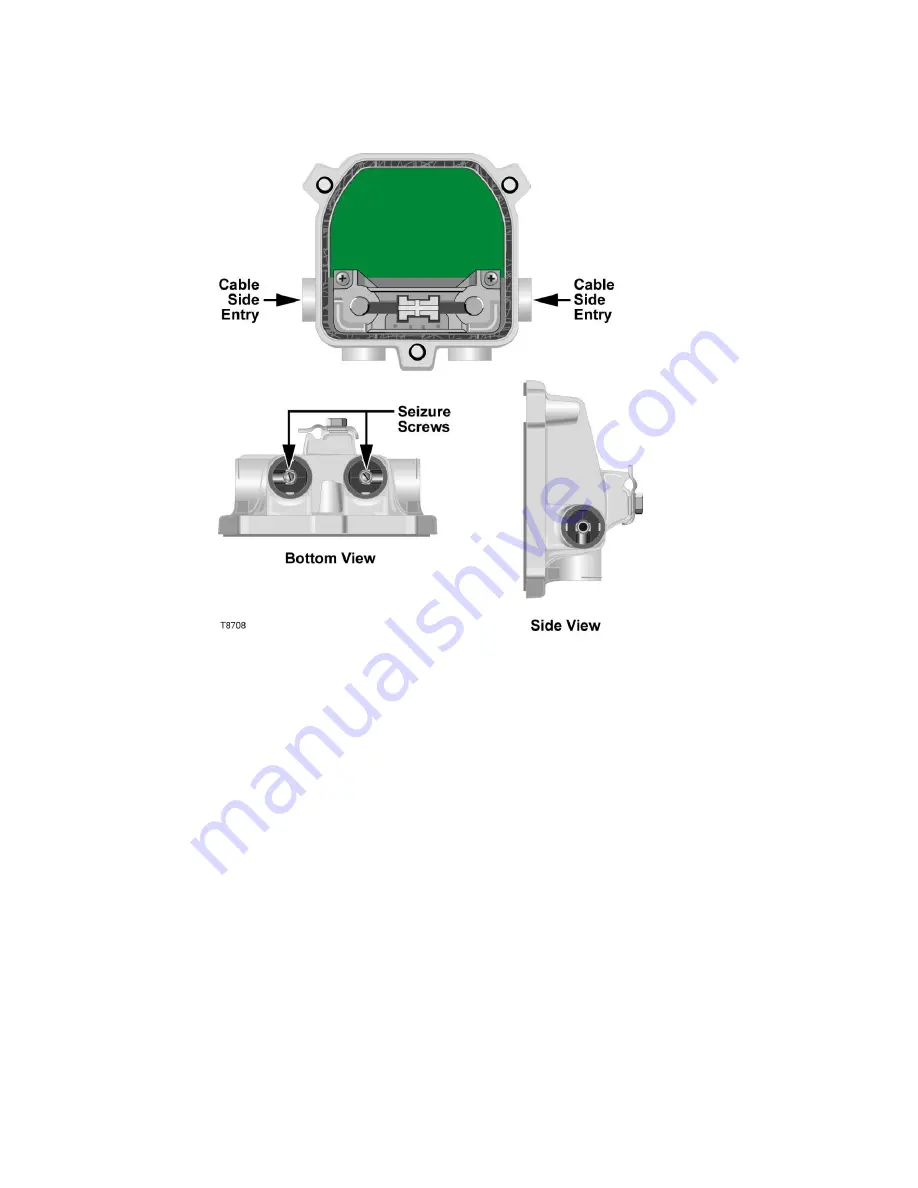

Using a 3/16-in. hex-head driver or 3/16-in. straight blade screwdriver, loosen

the two seizure screws inside the housing.

6

Thread the prepared KS-connectors into the housing at the cable side entry port

locations as shown in the figure above. Make sure to tighten the connector

according to the manufacturer‟s recommended torque specification, typically 15

ft-lb to 25 ft-lb (20.3 Nm to 33.9 Nm), but not to exceed 60 ft-lb (81.3 Nm).

7

Using a 3/16-in. hex-head driver or 3/16-in. straight blade screwdriver, tighten

the two seizure screws from 15 in-lb to 20 in-lb (1.7 Nm to 2.3 Nm). See the

diagram in step 5 for the location of the two seizure screws.

8

Replace the end plugs on the unused entry ports and torque with a 3/8-in. hex

wrench from 50 in-lb to 60 in-lb (5.6 Nm to 6.8 Nm).

9

Attach the faceplate to the housing. Refer to

To Mount the Faceplate

(on page

10

Attach the drop cable (RG-6 or RG-59) to the tap faceplate.

Important:

For any drop cables that will have AC power activated, be sure that

power blocking device(s) are installed at the home to prevent AC from passing to

subscriber televisions, set-top converters, or FM receivers. AC power must only

be allowed to pass to the telephony equipment requiring it.

Note:

Be sure to provide strain relief for the coax drop cable per manufacturer‟s

recommendation, and terminate all unused F-ports with 75

terminators.

Summary of Contents for Surge-Gap Multimedia Tap

Page 1: ...4013399 Rev C Surge Gap Multimedia Tap Installation and Operation Guide ...

Page 2: ......

Page 33: ...Preparing for Installation 4013399 Rev C 19 ...

Page 60: ......

Page 62: ...Chapter 3 Customer Support Information 48 4013399 Rev C ...

Page 70: ......

Page 73: ......