Page 27

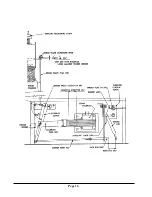

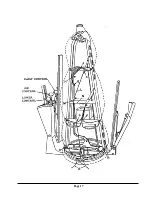

CISSELL FORM FINISHER

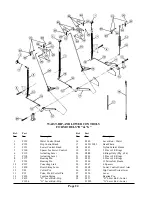

BLOWER ASSEMBLY(LOW BASE)

PARTS AND INSTALLATION

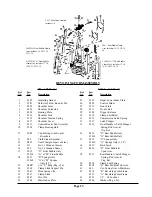

WHEN ORDERING PARTS OR MAKING INQUIRY, Specify Machine, Serial Number, Voltage and

Current.

Ref.

Part

No.

No.

Description

F-734

Blower Assembly Complete

less motor, guards, pulleys

and belt

1

F-363

Blower Pulley (1) 3/4 dia.

hole (AK-61)

2

PT332

Adjustment Bolt with square

nut, strap pad, mounting

bolt, nut and washer (1)

3

F-366

Shaft 3/4 dia. x 16 1/2

length

4

F-367

Cut-off (with speed nuts and

stove bolts) (1)

5

F-368

Blower Wheel (1)

6

F-369

Blower Housing (with cut-off)

7

F-371

Bearing Assembly

Ref.

Part

No.

No.

Description

8

F-372

Thrust Collar (1)

9

F-373

Bearing Insulator Cup (2)

10

F-374

Plastic Thrust Washer (2)

11

F-375

Blower Guard (1)

12

F-376

Belt Guard (1)

13

TU-2317

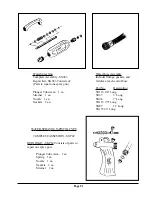

V-Belt (1) 4L-380

14

F1034

Motor Pulley with set screw

5/8 dia. hole (AK-34)

15

PT-47

Motor Support Bar

16

MTR88

Motor 1/2 HP

115/230/60/50/1

(consult factory for other

voltages)

P-36

Allen Head Wrench, 5/32

across flats (not

illustrated)

ELECTRIC MOTOR -- WHEN ORDERING, SPECIFY

VOLTAGE DESIRED. Other voltages and currents

available at additional cost.

Summary of Contents for FFCD

Page 3: ...Page 3 FF FORM FINISHER LOW BASE OVERALL DIMENSIONS...

Page 6: ...Page 6...

Page 16: ...Page 16...

Page 17: ...Page 17...