Chapter 2 Operating Principles

2-1.

Operation of Each Mechanism

2-13

CL-E700 series

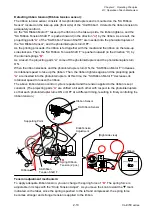

Detecting ribbon tension (Ribbon tension sensor):

The ribbon tension sensor consists of two photointerrupters and is mounted on the “SA Ribbon

Sensor” located on the take-up side (front side) of the “Unit Ribbon”. It detects the ribbon tension to

adequately control it.

As the “SA Ribbon Motor F” takes up the ribbon on the take-up side, the ribbon tightens, and the

“SA Ribbon Tension Shaft F” is pushed inward (in the direction “

a

”) by the ribbon. As a result, the

projecting parts “

A

” of the “SA Ribbon Tension Shaft F” are inserted into the photointerrupters of

the “SA Ribbon Sensor”, and the photointerrupters turn OFF.

As the printing proceeds, the ribbon is fed together with the media and the ribbon on the take-up

side slackens. Then, the “SA Ribbon Tension Shaft F” is pushed outward (in the direction “

b

”) by

the internal springs “

B

”.

As a result, the projecting parts “

A

” come off the photointerrupters and the photointerrupters turn

ON.

When the ribbon slackens and the photointerrupters turn ON, the “SA Ribbon Motor F” increases

its rotational speed to take up the ribbon. Then, the ribbon tightens again and the projecting parts

“

A

” are inserted into the photointerrupters. At this time, the “SA Ribbon Motor F” decreases its

rotational speed to loosen the ribbon.

The above ribbon tension control cycle is repeated and the tension applied to the ribbon is kept

constant. (The projecting parts “

A

” are shifted a bit each other with respect to the photointerrupters

so that each photointerrupter turns ON or OFF at a different timing, resulting in finely controlling the

ribbon tension.)

Tension adjustment mechanism:

To apply adequate ribbon tension, you can change the spring force of “

B

”. The spring force is

adjustable in 3 steps with the “Knob Tension Adjust”. As you move the knob toward the

mark

indicated on the label, since the spring is pushed to the left and compressed, the spring force

becomes stronger and stronger tension is applied to the ribbon.

KnobTension

Adjustment

SA Ribbon Sensor

Supporting Point

SA Ribbon

Tension Shaft F

Spring Ribbon

Tension (2 pcs.)

Ribbon

A

[Right side view]

a

b

B

Ribbon Sensor

A

Ribbon

Summary of Contents for CL-E700 Series

Page 1: ...Technical Manual CL E700 series Thermal Transfer Printer...

Page 5: ...Chapter 1 Specifications 1 1 CL E700 series CHAPTER 1 SPECIFICATIONS...

Page 15: ...Chapter 2 Operating Principles 2 1 CL E700 series CHAPTER 2 OPERATING PRINCIPLES...

Page 87: ...Chapter 3 Disassembly and Maintenance 3 1 CL E700 series CHAPTER 3 DISASSEMBLY AND MAINTENANCE...

Page 151: ...Chapter 4 Troubleshooting 4 1 CL E700 series CHAPTER 4 TROUBLESHOOTING...

Page 167: ...Chapter 5 Parts Lists CL E700 series CHAPTER 5 PARTS LISTS...

Page 172: ...Chapter 5 Parts Lists CL E700 series 5 6 DRAWING NO 1 General Assembly Rev 0...

Page 195: ...Chapter 5 Parts Lists 5 29 CL E700 series DRAWING NO 7 Unit Opepane Rev 0...

Page 203: ...Chapter 5 Parts Lists 5 37 CL E700 series DRAWING NO 9 SA2 Ribbon Unit Fan Rev 0...

Page 206: ...Chapter 5 Parts Lists CL E700 series 5 40 DRAWING NO 10 Accessories Rev 0 3 2 4 1 1 1 2 1 3...

Page 208: ...Chapter 6 Circuit Diagrams 6 1 CL E700 series CHAPTER 6 CIRCUIT DIAGRAMS...

Page 230: ...Appendices AP 1 CL E700 series APPENDICES...

Page 233: ...Appendices A Mounting Diagrams CL E700 series AP 4 2 Solder side...