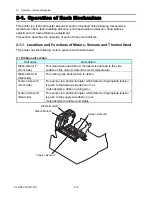

2-1. Operation of Each Mechanism

2-1-4. Printing and Ribbon Feed Mechanism

The major components of the printing and ribbon feed mechanism are:

(a) Head SA

(d) Ribbon Tension Shaft F/R SA

(b) Ribbon Motor F/R SA

(e) Tension Sensor SA (Front/Rear)

(c) Ribbon gear train

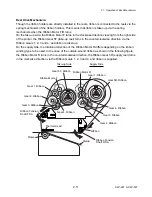

Ink ribbon is set to the printer using the ribbon holders. Ribbon is supplied from the supply reel and

is taken up by the take-up reel with adequate ribbon tension, via the Ribbon Tension Shaft R/F SA.

The Ribbon Tension Shaft R/F SA is always pushed outward by the internal springs, and, when

ribbon slacks, it moves outward. When ribbon tightens, it moves inward. (Refer to the figures on

the later pages.)

The same tension sensor is installed on the take-up and supply sides. The tension sensor on the

take-up side is used to detect the position of the Ribbon Tension Shaft F SA, i.e. the ribbon tension

on the take-up side. While, the tension sensor on the supply side is used to detect the position of

the Ribbon Tension Shaft R SA, i.e. the ribbon tension on the supply side.

The tension sensor on the take-up side is also used to detect a ribbon running condition, and that

on the supply side is used to detect the ribbon end.

On the take-up side, the Ribbon Motor F turns to take up ribbon. On the supply side, the Ribbon

Motor R turns to supply ribbon, while applying adequate back tension to ribbon to eliminate ribbon

slack. On the supply side, the rotational direction of the Ribbon Motor R differs depending on the

ribbon winding type to be used. According to the ribbon winding type (inside-wound (ink-in) ribbon

or outside-wound (ink-out) ribbon), the Ribbon Winding Selection switch must be correctly set.

Printing:

When printing with ink ribbon, ink on the ribbon is melted by the heated thermal element of the

Head SA and is transferred on the media surface.

Taking up Ribbon:

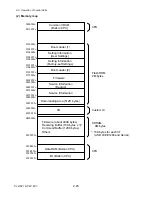

Ribbon will be taken up on the take-up side as follows:

(1) As media is fed, ribbon is also fed by the friction force produced between media and the Head

SA.

(2) Ribbon slacks and the tension sensor on the take-up side turns OFF as the Ribbon Tension

Shaft F SA is pushed outward.

(3) The Ribbon Motor F starts to turn and ribbon is taken up.

(4) Ribbon tightens and the tension sensor on the take-up side turns ON. Then, the Ribbon Motor

F stops.

Supplying Ribbon:

On the supply side, the Ribbon Motor R turns to supply ribbon, while applying adequate back

tension. In the same way as on the take-up side, the tension sensor on the supply side detects the

ribbon tension to keep the ribbon tension constant. However, when printing is made and ribbon is

fed, the tension sensor on the supply side turns ON since ribbon is tightened at this time.

CLP-621 & CLP-631

2-10

Summary of Contents for CLP-621

Page 1: ...Technical Manual CLP 621 CLP 631 Thermal Transfer Barcode Label Printer JM74961 00F 1 00E 0701...

Page 2: ...CLP 621 CLP 631 ii Copyright 2007 by CITIZEN SYSTEMS JAPAN CO LTD...

Page 4: ...CHAPTER 1 SPECIFICATIONS CLP 621 CLP 631...

Page 13: ...CHAPTER 2 OPERATING PRINCIPLES CLP 621 CLP 631...

Page 73: ...CHAPTER 3 DISASSEMBLY AND MAINTENANCE CLP 621 CLP 631...

Page 126: ...CLP 621 CLP 631 CHAPTER 4 TROUBLESHOOTING...

Page 138: ...CLP 621 CLP 631 CHAPTER 5 PARTS LISTS...

Page 166: ...Chapter 5 Parts Lists CLP 621 CLP 631 5 29 DRAWING NO 7 Control Panel Unit Rev 0 4 3 2 1 5...

Page 177: ...Chapter 5 Parts Lists CLP 621 CLP 631 5 40 DRAWING NO 10 Accessories Rev 0 3 2 4 1...

Page 179: ...CHAPTER 6 CIRCUIT DIAGRAMS CLP 621 CLP 631...

Page 208: ...APPENDICES CLP 621 CLP 631...

Page 212: ...B Mounting Diagrams AP 5 CLP 621 CLP 631 Main PCB Solder side...

Page 214: ...B Mounting Diagrams AP 7 CLP 621 CLP 631 B 3 Ribbon Main PCB Parts side Solder side...

Page 217: ......