2-2. Operation of Control Parts

trol Parts

CLP-621 & CLP-631

2-30

CLP-621 & CLP-631

2-30

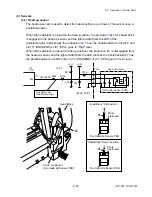

(4-3) Head driver

(4-3) Head driver

The head driver is incorporated in the Head SA.

The head driver is incorporated in the Head SA.

When printing, pin 116 (HDVON) of IC11 (Custom IC) goes to "High" level, and DTR1 and

TR1 turn ON. Thus +24V is supplied to the thermal head (Head SA).

When printing, pin 116 (HDVON) of IC11 (Custom IC) goes to "High" level, and DTR1 and

TR1 turn ON. Thus +24V is supplied to the thermal head (Head SA).

The print data is sent from the Custom IC (IC11) to the head driver to select the thermal

elements to be heated. The data is sent via HD1 to 3, HDSTB, HDCLK and HDLAT lines

(pins 110, 111, 113, 108, 115 and 107 of IC11).

The print data is sent from the Custom IC (IC11) to the head driver to select the thermal

elements to be heated. The data is sent via HD1 to 3, HDSTB, HDCLK and HDLAT lines

(pins 110, 111, 113, 108, 115 and 107 of IC11).

According to the print data, the thermal head heats the thermal elements to print dots on

thermal transfer paper. The width of heating pulse will be changed according to the head

temperature to keep the printing density constant.

According to the print data, the thermal head heats the thermal elements to print dots on

thermal transfer paper. The width of heating pulse will be changed according to the head

temperature to keep the printing density constant.

CN4

Thermal

Head

5,6,8,11,12

20,22

1-4,23-26

HDSTB1-3

HDCLK

HDDAT1-3

HDLAT

+3.3V

VHEAD

10,14,17

19

P174-

176

P177

P178

P179

IC11

Custom IC

HDLTH

107

HDSTB

108

HDCLK

115

HDATA1-3

110,

111,

113

HDVON

HCVON

HDVON

116

HCVON

117

+24V

R76

R77

TR1

DTR1

+5V

R81

R82

DTR2

R84

VHEAD

DTC143EUA

DTC143EUA

P170

D2

2SJ553S

TR2

2SJ647

D1

+3.3V

IC1

CPU

D3

+3.3V

R83

R78

R80

R79

P166

P171

P173

P164

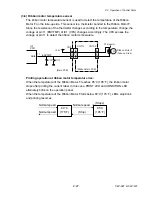

Head supply voltage ON/OFF

Thermal element abnormality check ON

Head power supply monitor

Thermal element abnormality check

[Main PCB]

When driving: +24V

When checking: +5V

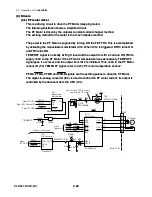

HD1-3

HDSTB

HDCLK

HDLAT

7

5

6

2-3

13

15

14

16-18

16

18

7,9,15

174

PRT_MODE

IC1

CPU

P74

Fixed to L.

+3.3V

R159

HDTHM1

P167

P162

P172

P168

VHEADMON

HEADRES

P169

P163

ANI4

9

ANI5

10

A1-3

B1-3

A4

B4

A5

B5

A6

B6

IC21A

27

Summary of Contents for CLP-621

Page 1: ...Technical Manual CLP 621 CLP 631 Thermal Transfer Barcode Label Printer JM74961 00F 1 00E 0701...

Page 2: ...CLP 621 CLP 631 ii Copyright 2007 by CITIZEN SYSTEMS JAPAN CO LTD...

Page 4: ...CHAPTER 1 SPECIFICATIONS CLP 621 CLP 631...

Page 13: ...CHAPTER 2 OPERATING PRINCIPLES CLP 621 CLP 631...

Page 73: ...CHAPTER 3 DISASSEMBLY AND MAINTENANCE CLP 621 CLP 631...

Page 126: ...CLP 621 CLP 631 CHAPTER 4 TROUBLESHOOTING...

Page 138: ...CLP 621 CLP 631 CHAPTER 5 PARTS LISTS...

Page 166: ...Chapter 5 Parts Lists CLP 621 CLP 631 5 29 DRAWING NO 7 Control Panel Unit Rev 0 4 3 2 1 5...

Page 177: ...Chapter 5 Parts Lists CLP 621 CLP 631 5 40 DRAWING NO 10 Accessories Rev 0 3 2 4 1...

Page 179: ...CHAPTER 6 CIRCUIT DIAGRAMS CLP 621 CLP 631...

Page 208: ...APPENDICES CLP 621 CLP 631...

Page 212: ...B Mounting Diagrams AP 5 CLP 621 CLP 631 Main PCB Solder side...

Page 214: ...B Mounting Diagrams AP 7 CLP 621 CLP 631 B 3 Ribbon Main PCB Parts side Solder side...

Page 217: ......