iDP3240 SERVICE MANUAL

2

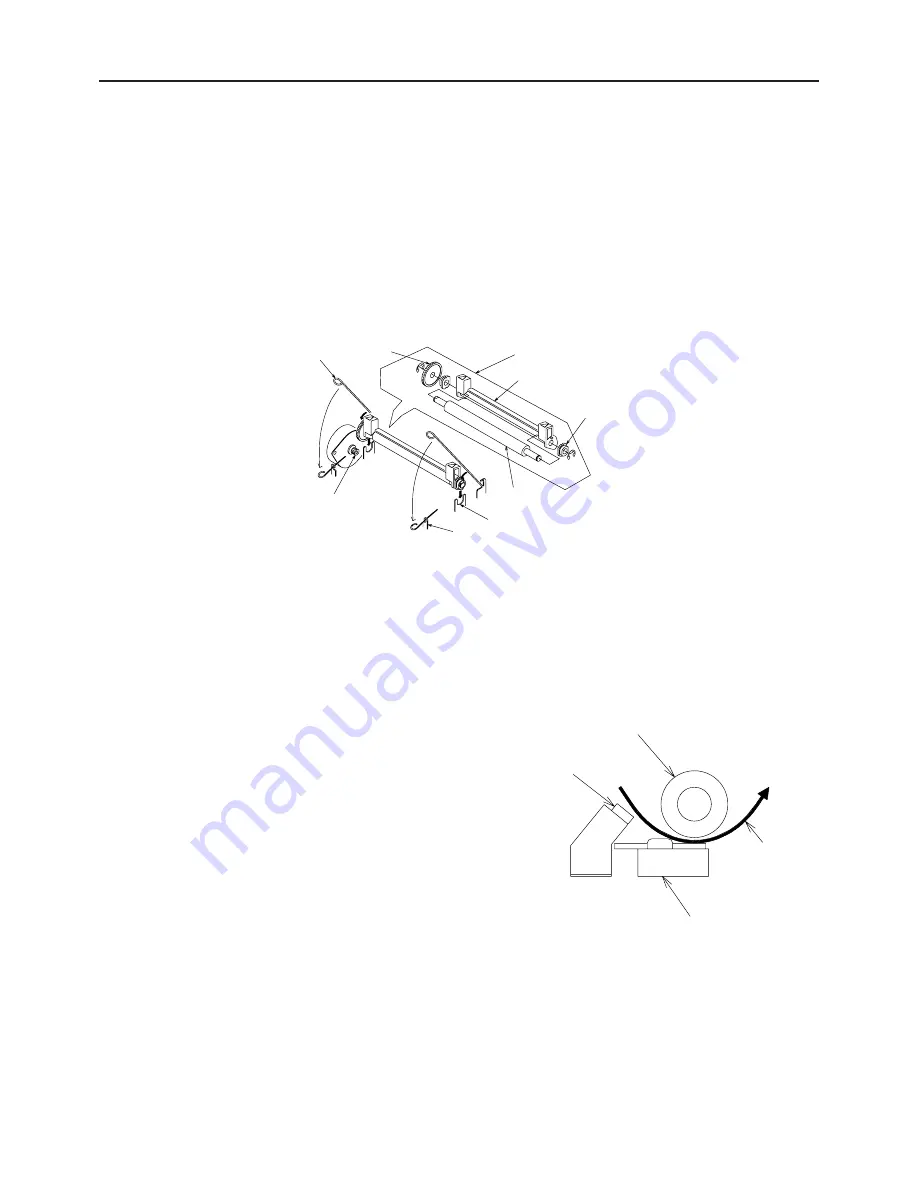

1.3 Sensor mechanism

1.3.1 Paper sensor

The paper sensor is located immediately before

the thermal head to detect whether recording

paper is present or not. Applying electrical

power to the thermal head while recording paper

is not inserted could result in damage to the head

or reduce the service life of it. The paper sensor

is provided to help prevent this, as well as to

detect whether recording paper is inserted or not

in the case of auto loading.

Platen roller

Paper sensor

Recording paper

Thermal head

1.2 Mechanism for attaching and detaching the platen roller

The platen roller, which is a part of the mechanism for feeding recording paper, is removable

with this printer. The platen roller, which has the platen gear, platen bushings and platen holder

attached, comprises a platen roller unit. When this unit is placed in the U-formed bearings of the

chassis, the platen gear engages the motor gear. The wire springs, with one end anchored to the

chassis, press against the platen bushings to keep the roller in contact with the thermal head. The

platen roller unit can be attached or removed by hooking or unhooking the movable ends of the

wire springs to or from the hooks on the chassis.

Wire spring

Motor gear

Platen gear

Platen roller (Platen roller unit)

Platen holder

Platen bushing

Platen roller

Chassis U-formed bearing

Chassis hook

Summary of Contents for iDP3240

Page 1: ...LINE THERMAL PRINTER MODEL iDP3240 Rev 1 0 First created Feb 10th 2000 Service Manual...

Page 2: ...i REVISION Rev No Date Content Rev 1 0 Feb 10th 2000 First created...

Page 16: ...iDP3240 SERVICE MANUAL 13 3 2 Exploded View 2 5 4 3 71 31 30 29 28 45 44 43 41 52 51 50 49 48...

Page 23: ...iDP3240 SERVICE MANUAL 20 4 3 2 Control PCB Assy Reverse side of the board...

Page 24: ...iDP3240 SERVICE MANUAL 21 4 3 3 Control PCB Assy Top side of the board Parallel Interface...

Page 25: ...iDP3240 SERVICE MANUAL 22 4 3 4 Control PCB Assy Reverse side of the board...

Page 33: ...iDP3240 SERVICE MANUAL 30 6 OUTLINE DRAWING FEED ERROR POWER 9 37 201 119 5 186 123...