28

PRU·PMU·PHU SERIES SPECIFICATIONS

7.3 PHU (Paper Holding Unit)

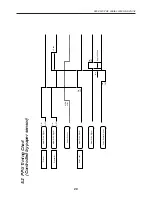

7.3.1 Loading a Paper Roll

Paper winding

direction

1

Check the winding direction of the paper roll, and then insert the paper roller

into the paper roll.

2

Install the paper roller (on which paper roll was set) in the paper holder.

Paper roller