Civemasa Implementos Agrícolas

37

CRO 4.0

Maintenance

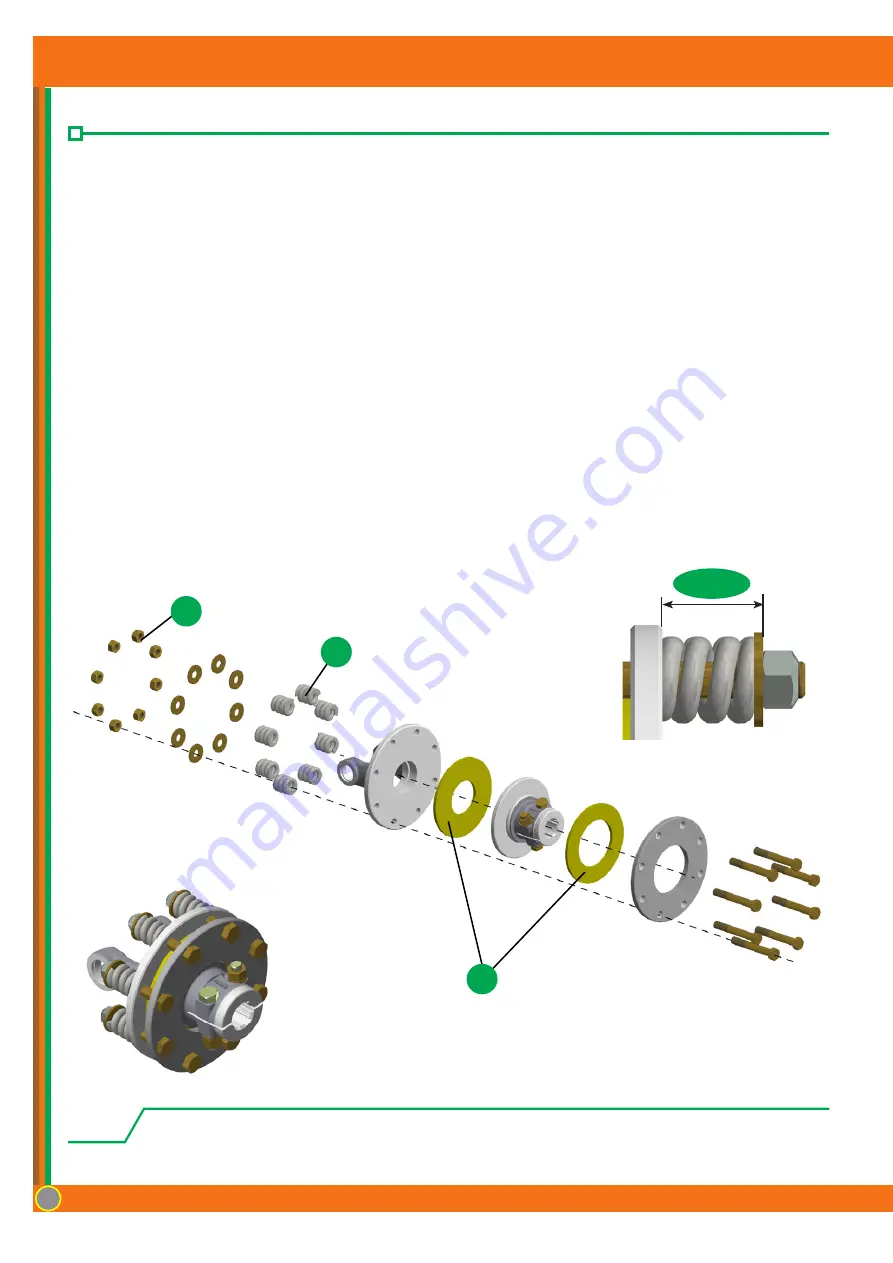

Slip clutch maintenance

• Lubricate all grease fittings;

• Check the oil level;

• Carry out the following procedures on the slip clutch:

A) Make note on the average length of the adjusting springs before disassembling it.

B) Disassemble and sandpaper all parts that are glued with the friction plates.

C) Being the clutch unassembled, the friction plates must turn freely over the metallic

parts.

D) The friction plates (B) must be changed when they reach less than 1.5 mm of

thickness.

E) After this procedure, assemble the slip clutch again.

F) The adjusting springs (A) must be adjusted to have the same length before the

disassembling.

G) If the slip clutch keeps activating constantly on normal working conditions even after

the maintenance steps, tighten up the nuts (C) proportionally until it reaches a measure of

28 mm

.

B

B

28mm

28mm

C

C

A

A

Carry out a periodic verification of the spring (A) pressure, always keeping

it with 28mm.

NOTE