13

3.

Commissioning the Filter

3.1 Introduction

With the system fully plumbed (see below) and the valve programmed commissioning can

start.

3.2 Backwash

When the system is fully functional the backwash will happen at the pre-set time (see

programming the valve section). However, running a manual backwash during commissioning

is the best way of removing air from the system, bedding in the media and flushing the

system.

Make sure the water inlet and outlet are closed. Press and hold the regeneration button for 5

seconds. The motor will turn and the piston will move to the backwash position. Slowly half

open the water inlet to the system, and then slowly open the outlet to allow the air to be

purged from the system. Once this has been done you can fully open the inlet and outlet and

allow the system to continue through the backwash cycle, this will allow you to check for leaks

and also purge any remaining air from the system. After a backwash the system will move

through a short rinse cycle and then stop in the service position.

For new systems or after a media change it maybe necessary to run two backwashes to fully

wash the media (check the water at the end of the backwash is running clear).

For TURBIDEX please see below.

Initial backwash instructions for Turbidex filtration media.

Due to the naturally occurring dust and fine particles found in zeolites it is important to

thoroughly clean the new bed to prevent plugging of the distributor slots. Zeolite fines are

crystalline in structure and may get wedged in the slots, becoming very difficult to remove.

Important:

Throughout this procedure, do not place the unit into rinse or service until you are

sure the bed has been cleaned of fines.

Always start the unit in backwash and slowly open the by-pass valve until the unit is full of

water (as evidenced by a gradual flow to drain). Shut off the by-pass and allow the unit to

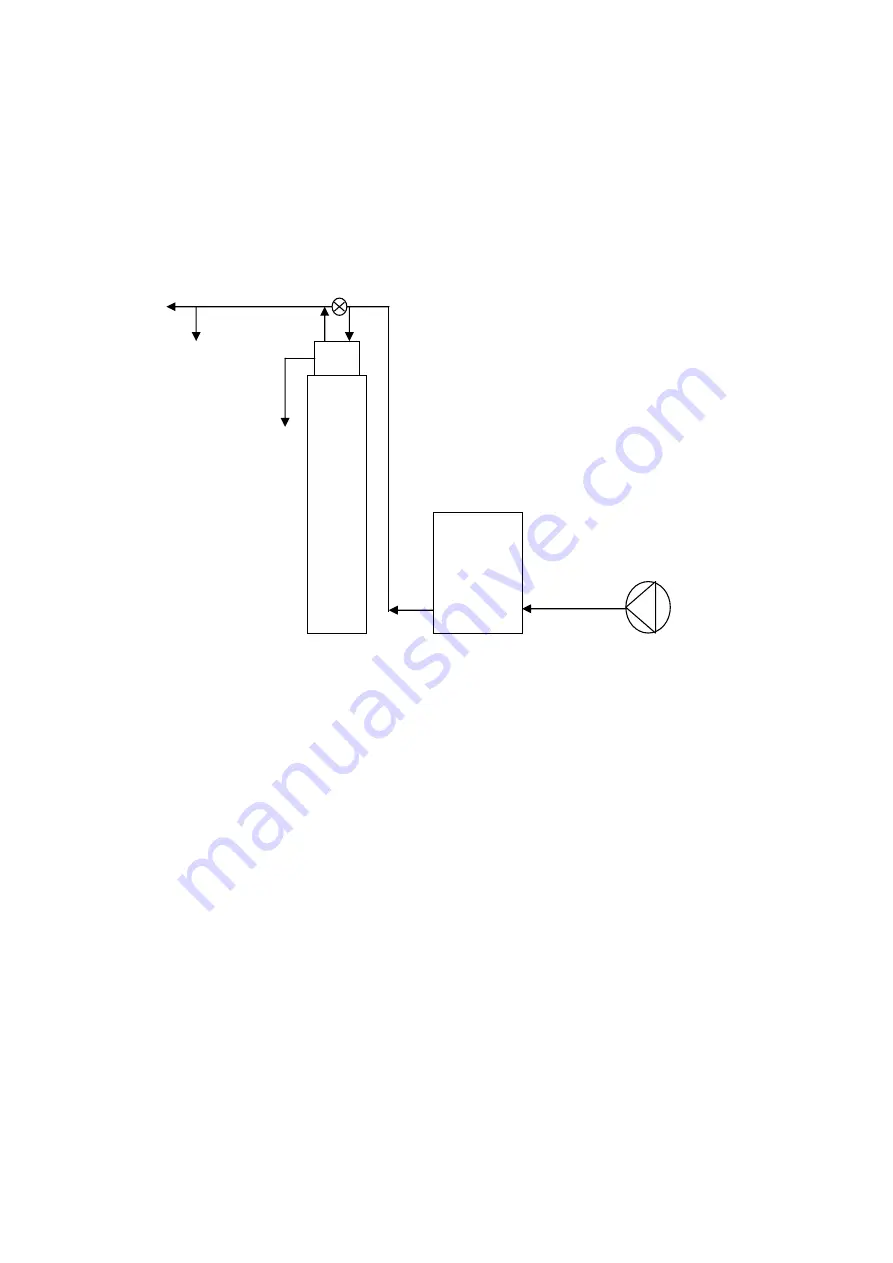

Pressure

tank to

control

pump

F

il

te

r

sampling

point

OUTLET

Drain

Pump

Bypass

Summary of Contents for Water Specialist CI WS1

Page 19: ...19 Troubleshooting...

Page 20: ...20...

Page 21: ...21...

Page 22: ...22 Manual 018 0...