Description of the generator

10

3.4.

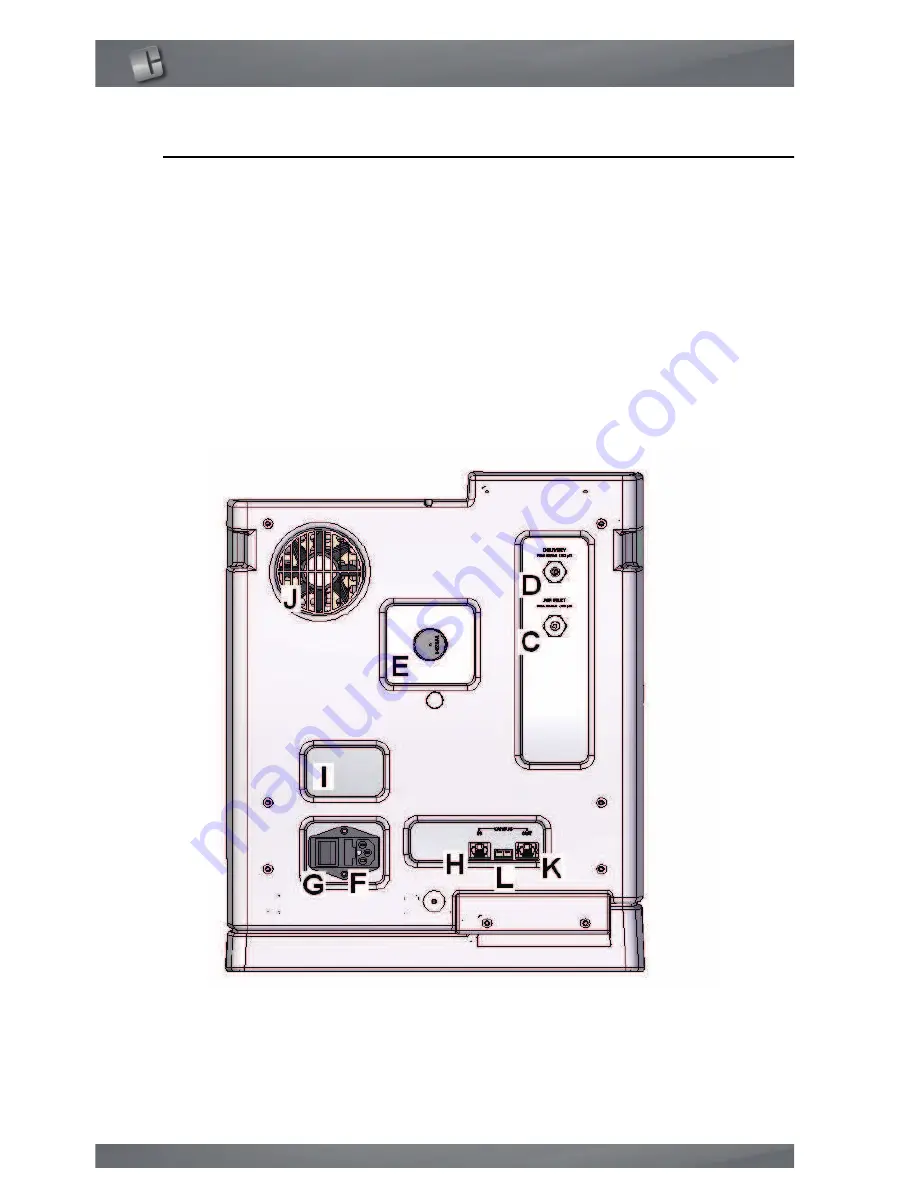

Rear view

C.

AIR INLET: pneumatic connection for compressed air line inlet.

D.

NITROGEN OUTLET: pneumatic connection for the generator’s nitrogen

delivery.

E.

PRESSURE REGULATOR nitrogen delivery

F.

CONNECTOR for electric power supply cable

G.

POWER" KEY: ON-OFF switch; includes housing for the main fuse

H.

CAN BUS IN for connection to CPU

I.

IDENTIFICATION LABEL: states the model, serial number (SN) and electrical

specifications

J.

VENTILATION GRILLE

K.

CAN BUS OUT

L.

CAN BUS ADDRESS (DIP switch)

FIGURE 3.3.2. Rear view