31

❑

Thread the nylon clevis onto the pushrod wire and snap the clevis

into the

outermost hole

in the control horn.

☞

Hold the pushrod wire with a pair of pliers to prevent it from turning

or twisting when installing the clevis.

❑

Remove the masking tape from the elevator and double-check that

both the servo horn and the elevator are still centered. If the elevator

is not centered, adjust the clevis until it is.

❑

Move the elevator up and down several times to ensure that the pushrod assembly does not bind. It should operate smoothly in

both directions.

❑

Kwik Bond Thin C/A

❑

# 1 Phillips Head Screwdriver

❑

Needle Nose Pliers

❑

Excel Modeling Knife

❑

Electric Drill

❑

1/16" & 5/64" Drill Bits

❑

Ernst Airplane Stand

❑

Ruler

❑

Pencil

❑

Masking Tape

YOU'LL NEED THE FOLLOWING PARTS FROM THE KIT:

YOU'LL NEED THE FOLLOWING TOOLS AND SUPPLIES:

SECTION 16: RUDDER CONTROL SYSTEM INSTALLATION

❑

(1) 6-1/8" Threaded Wire w/Z-Bend

❑

(1) Nylon Control Horn w/Backplate

❑

(1) Nylon Clevis

❑

(2) M2 x 12mm Machine Screws

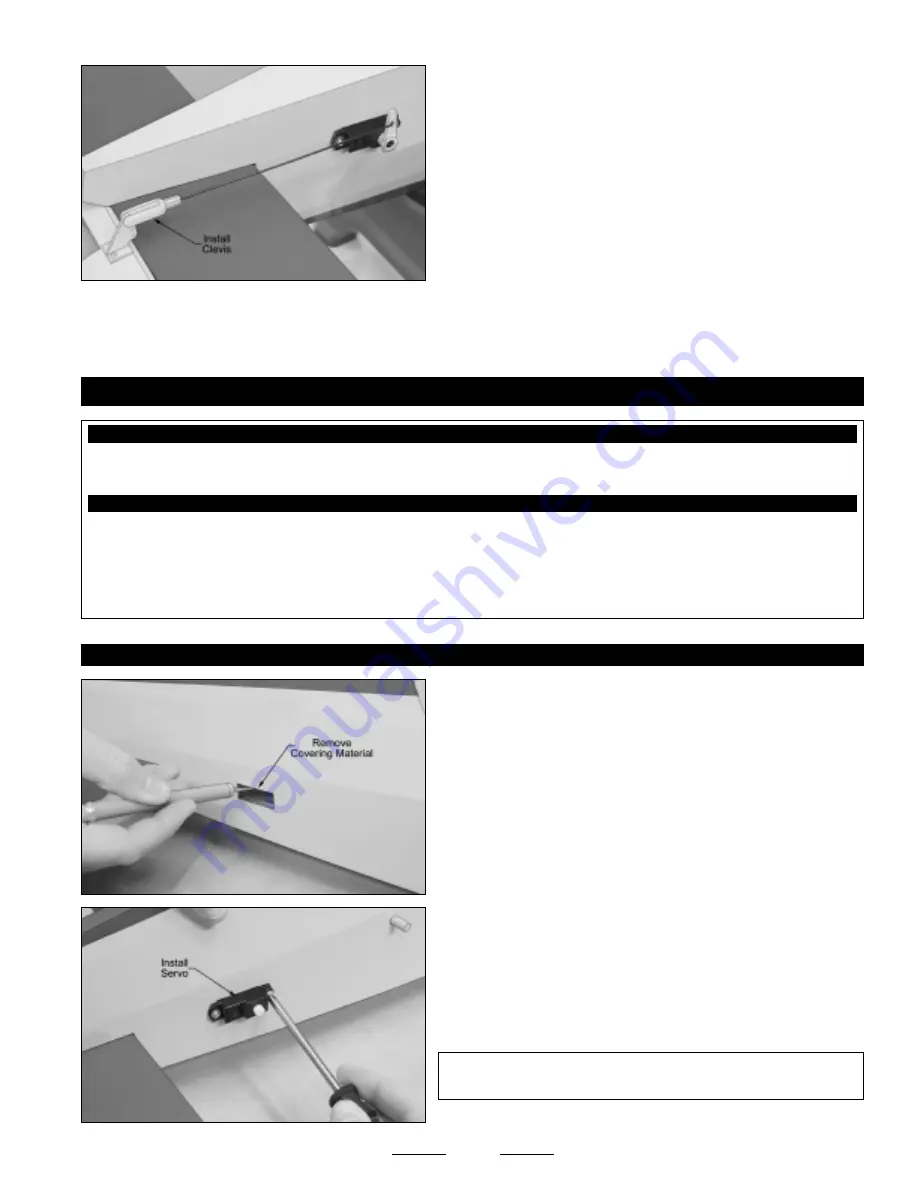

STEP 1: INSTALLING THE RUDDER SERVO

❑

Install the rubber grommets and brass collets onto your rudder servo,

making sure to install the collets with the flanges toward the

bottom

of

the servo.

❑

Install the rudder servo, making sure to drill 1/16" diameter pilot holes

for the mounting screws.

✦

✦

✦

✦

✦

IMPORTANT

✦

✦

✦

✦

✦

The servo output shaft should be toward the front

of the fuselage, as shown.

❑

Cut away and remove the covering material from over the rudder

servo mounting hole in the right side of the fuselage. The servo

mounting hole is located 6-1/4" in front of the rudder hinge line and

1-1-2" up from the bottom of the fuselage.

☞

Again, you may need to enlarge the hole to fit your rudder servo.

Continued On Next Page

☛

☛

☛

☛

☛