1

Revised 09/09

Smog-Hog

PCN Series Models

1. INTRODUCTION

1.1 DESCRIPTION AND OPERATION

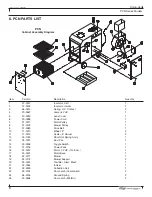

The Smog-Hog PCN is a portable electronic air cleaner

designed to eliminate particulate as it is generated.

Contaminant is captured at its source by a unit-mounted

hood, then conveyed through a duct network to the

precipitator where it is collected. Clean air is then re-

circulated back to the work area.

As air approaches the precipitator, it passes though a

reusable, aluminum mesh mechanical pre-filter which

aids air distribution and removes large particles.

Pre-filtered air then passes through an ionizer where

particles are charged by corona discharge from a series

of small diameter charged tungsten wires centered

between grounded plates. Particles then pass through

a collection cell, consisting of alternately charged and

grounded parallel aluminum plates. Charged plates

at the same polarity as the charged particles repel

the particles toward the grounded plates which, in

turn, attract the particles. Air next passes through

a centrifugal blower where it is exhausted vertically

through a centrifugal blower where it is exhausted

vertically through an adjustable outlet grille, back to the

work space.

An integrally mounted power pack converts 115 volt,

single-phase AC power to the high voltage DC required

for ionizer and collection cell operation.

1.2 ELECTRICAL CHARACTERISTICS

The unit is rated for 115 VAC (volts alternating current),

single phase, 60 Hz operation. It has a 10´ power cord

with grounded plug and internal high voltage wiring.

1.3 SPECIFICATIONS

Power Requirements: 115V, single phase, 60 Hz*,

7.6 amps

Precipitator Voltage: Ionizer: 11,000 volts DC

Collection Cell: 6,000 volts DC

Motor:

1⁄2 HP, totally enclosed

Weight:

400 lbs. (181 Kg)

Overall Dimensions: Length

Width

Height

42˝

28˝

44˝

106.7 cm 71.1 cm 111.8 cm

Cabinet:

16-gauge steel

Air Cleaning Capacity: 1,000 CFM*** (1699M

3

H)

Capture Distance:

18˝ (45.7 cm) max.

recommended

Swing Arm Reach:

132˝, 360° radius

Duct:

8˝ diameter x 132˝ long

Hood Size:

18˝ x 12˝ oval

Wheels:

Two 8˝ (20.3 cm) wheels

and two 5˝ (12.7 cm)

Swivel locking casters

*50 Hz optional

** Factory set. Nominal airflow rating

2. INSTALLATION

2.1 PACKAGING

The Smog-Hog PCN is shipped in three containers.

One consists of the main cabinet and operating

components. The second is the factory-assembled

extraction arm with duct in place. The third is the hood.

2.2 INSPECTION NOTE

Upon receipt of your unit, check for any shipping

damage. A damaged carton indicates that the

equipment may have received rough handling during

shipping that may have caused possible internal

damage. Notify your delivery carrier and enter a claim if

any damage is found.

2.3 INSTALLING THE EXTRACTION ARM

ASSEMBLY

The top of the PCN cabinet has eight 5/16-18 threaded

studs protruding upward from the cabinet, and equally

spaced around the air entry opening. The mating

extraction arm mounting flange is ready for installation,

and the mounting hardware (nuts and split ring lock

washers) is in a plastic bag inside the main cabinet.

The extraction arm assembly is approximately 50 lbs,

but because of its size, may be best positioned by two

people.

The extraction arm support spring is in place on the

assembly, with a protective shipping retainer box

strapped in place (these must be removed before

operating the unit). All pivot points are tightened

slightly to keep arms from moving during handling.

This assembly is shipped for installation so that the

arm nearest the cabinet is in the vertical position when

the bearing flange is being bolted down. With this arm

extending up from the top of the cabinet, a ceiling

height of about 10´ is required for adequate clearance.

Refer to the SA Installation and Owner’s Manual for

instructions on assembling the extraction arm or making

field adjustments.

Sharp pulls on the arm or hood should be avoided

since damage to the arm components could result.

3. OPERATION

Do not use the PCN where high concentrations of

flammable materials may be present. If in doubt,

consult UAS.

3.1 TURNING THE UNIT ON

The PCN is provided with 10´ of pre-wired type 3-SJ

electrical cord with a three-prong male plug. To operate

the unit:

!

CAUTION

!

CAUTION

Summary of Contents for UAS SMOG-HOG PCN

Page 1: ...OWNER S MANUAL PORTABLE ELECTROSTATIC PRECIPITATOR SMOG HOG PCN ...

Page 11: ...7 Revised 09 09 Smog Hog PCN Series Models 7 TROUBLESHOOTING FLOWCHART ...

Page 14: ...10 Revised 09 09 Smog Hog PCN Series Models This page intentionally left blank ...

Page 15: ...11 Revised 09 09 Smog Hog PCN Series Models This page intentionally left blank ...