5

Revised 09/09

Smog-Hog

PCN Series Models

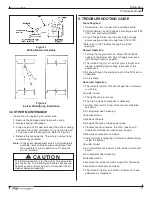

5.4 DETERMINING THE LOSS OF HIGH

VOLTAGE

As components build up dirt, the indicator light dims

then goes out at a point approximately 3.5KV cell

voltage. If satisfactory operating voltage is present at

the ionizer and cell and the light is out, the problem is

either a defective indicator light or light circuit.

If no voltage is present at the cell, and the indicator light

is out:

1. Remove the cell and depress the door interlock

switch.

2. If the indicator light comes on, the problem is in the

cell. Check for the following:

a. Excessive build up between cell plates.

b. Something lodged between the cell plates, bowed

or bent plates, etc.

c. Cracks in any of the eight cell insulators, carbon

tracking or other insulator damage.

3. If the indicator light remains off with the cell out of

the unit, remove the ionizer and activate the power

supply.

4. If the indicator light comes on, the problem is in the

ionizer. Check for the following:

a. Broken or loose ionizer wires.

b. Excessive build up on insulator(s).

c. Cracked or broken insulator(s).

5. If the light remains out with both the ionizer and cell

removed, remove the side access panel and check

out the high voltage power pack. See Figure 6.

a. Remove both high voltage leads from the end of

the power pack.

b. Measure high voltage (use probe) at terminal

No. 8 (output to ionizer) and terminal No. 7

(output to collector).

c. If no voltage is present or voltage is below

minimum, replace the power pack.

Note:

Minimum reading with high voltage wires

removed: 11KV at terminal No. 8 (ionizer) and

7KV at terminal No. 7 (collector).

6. If voltage is present and within limits, check for:

a. Short in the high voltage lead wires.

b. Cracked or broken cabinet insulators.

5.5 CHECKING AIR MOVEMENT

(BLOWER AND DRIVE)

1. If the unit has deficient airflow:

a. Check for any type of restriction in the pick-up

hood, flex hose or main unit.

b. Remove the pre-filter, cell and ionizer components

and check for an obstruction at the diffuser plate

directly above them. If none is present, check the

components for excessive dirt build up.

c. If components are clean, remove the side access

panel and check for:

i. Loose or broken belt

ii. Defective drive motor

iii. Loose pulley

The belt should have approximately 1⁄2” of play when

depressed with one finger. Having the belt set too

loose causes slippage and reduces airflow. Having

the belt set too tight causes an over current condition

in the motor. The resulting higher temperature

shortens motor winding and bearing life.

Figure 5

Power Pack Terminal Connections

!

CAUTION

Summary of Contents for UAS SMOG-HOG PCN

Page 1: ...OWNER S MANUAL PORTABLE ELECTROSTATIC PRECIPITATOR SMOG HOG PCN ...

Page 11: ...7 Revised 09 09 Smog Hog PCN Series Models 7 TROUBLESHOOTING FLOWCHART ...

Page 14: ...10 Revised 09 09 Smog Hog PCN Series Models This page intentionally left blank ...

Page 15: ...11 Revised 09 09 Smog Hog PCN Series Models This page intentionally left blank ...