Planned Maintenance Intervals

7-11

Section 7. Planned Maintenance and Lubrication

NOTES:

*

Air filter change interval may be determined by using an air

restriction indicator.

** Hydraulic filter change interval may be determined by hydraulic

filter restriction indicator.

A

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

B C D E

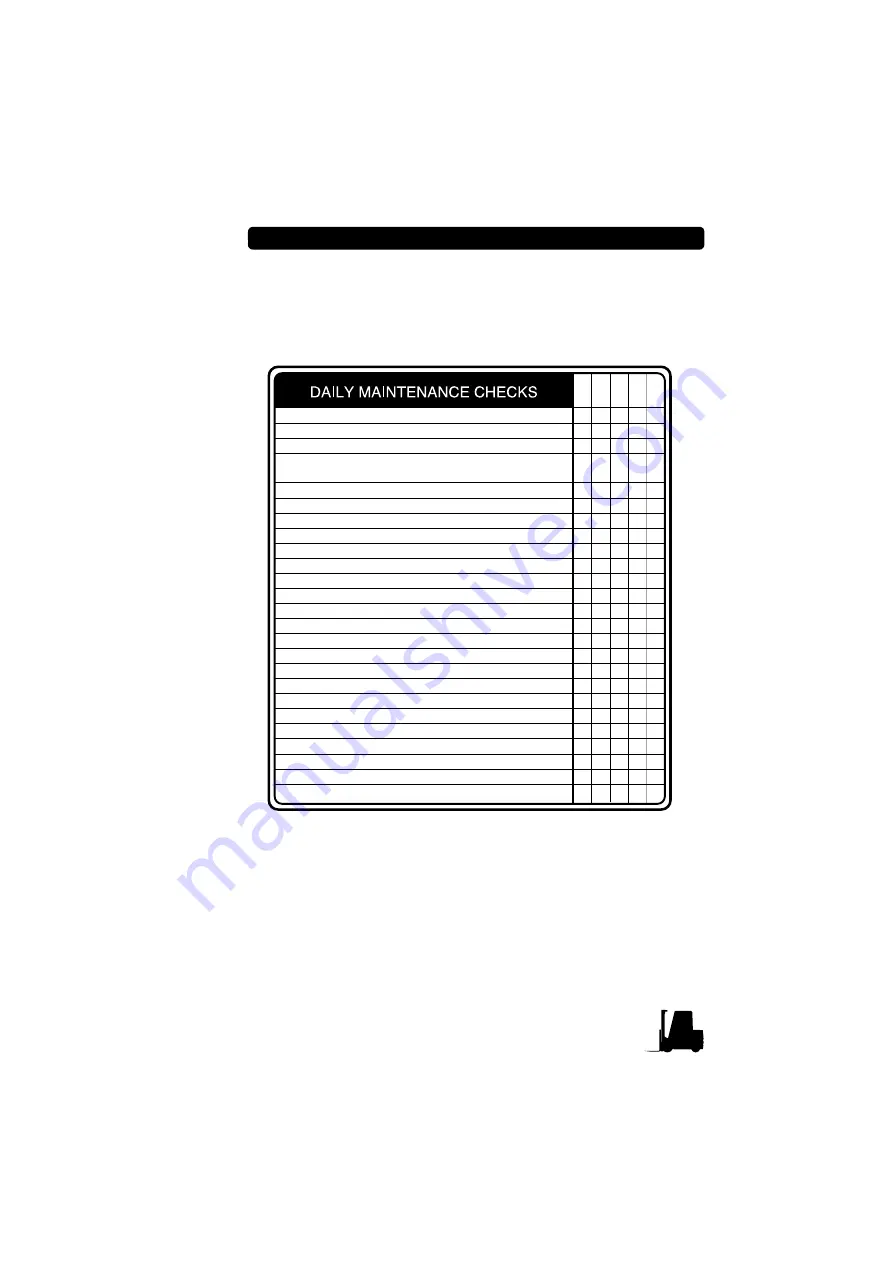

Check truck for obvious damage and leaks.

Check fuel system for leaks, etc.

Check capacity, warning plates and decals.

Check condition of tires and wheels. Remove embedded

objects. Check air pressure.

Check for missing or loose wheel lugs nuts.

Check engine oil level.

Check engine coolant level (radiator and recovery tank)

Check transaxle fluid level

Check fuel level.

Check hydraulic sump oil level.

Check gauges and instruments.

Check warning lights and hour meter.

Check overhead guard condition and bolts.

Check horn operation and other warning devices.

Check steering operation.

Check service brake operation.

Check parking brake operation.

Check parking brake linkage for damage, broken parts.

Check directional and speed controls operation.

Check accelerator and engine speed operation.

Check lift, tilt and aux. operation.

Check upright, lift chains and fasteners.

Check carriage or attachments and forks.

Check seat deck hold-down latch for correct locking.

Check optional safety equipment. (alarms, lights etc.)

Summary of Contents for C15 D

Page 2: ......

Page 6: ...iv...

Page 16: ...1 4 Seat Belts Seat Belts ALWAYS BUCKLE UP Seat belts can reduce injuries...

Page 30: ......

Page 88: ...5 8...

Page 107: ...PM Report Form 7 13 Section 7 Planned Maintenance and Lubrication...

Page 124: ...7 30...

Page 142: ......

Page 143: ......