7-28

How to Perform Planned Maintenance

Lift Chain Inspection and Measurement

Inspect and lubricate the lift chains every PM (50-250 hours). When

operating in corrosive environments, inspect the chains every 50

hours. During the inspection, check for the following conditions:

• Rust and corrosion, cracked plates, raised or turned pins,

tight joints, wear, and worn pins or holes.

• When the pins or holes become worn, the chain becomes

longer. When a section of chain is 3% longer than a section

of new chain, the chain is worn and must be discarded.

• Chain wear can be measured by using a chain scale or a

steel tape measure. When checking chain wear, be sure to

measure a segment of chain that moves over a sheave. Do

not repair chains by cutting out the worn section and joining

in a new piece. If part of a chain is worn, replace all the

chains on a truck.

Lift Chain Lubrication

Lift chain lubrication is an important part of your maintenance

program. The lift chains operate under heavy loadings and function

more safely and have longer life if they are regularly and correctly

lubricated. CLARK chain lubricant is recommended; it is easily

sprayed on and provides superior lubrication. Heavy motor oil may

also be used as a lubricant and corrosion inhibitor.

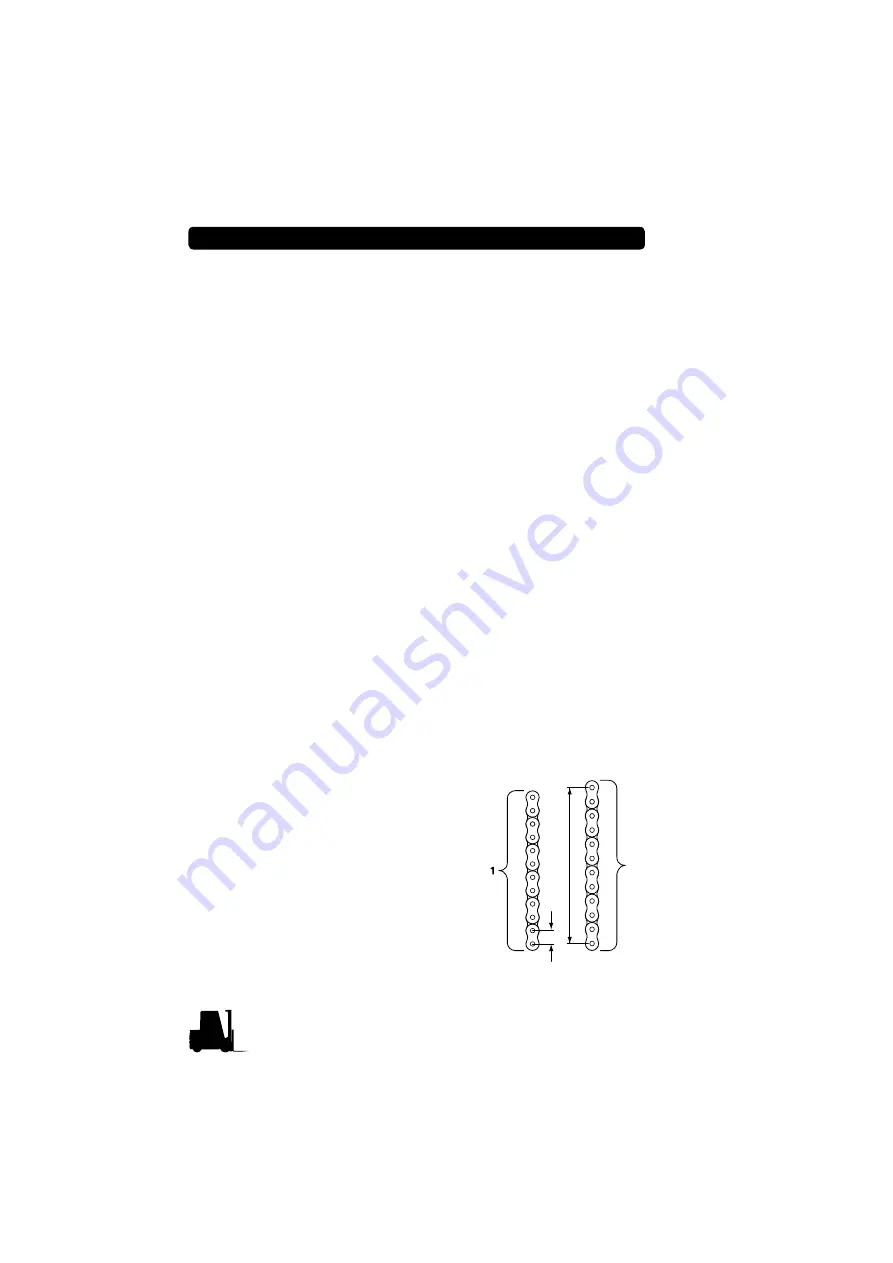

Lift Chain Wear and Replacement Criteria:

1. (NEW CHAIN LENGTH) The

distance from the first pin

counted to the last pin counted

in a span while the chains are

lifting a small load.

2. (WORN CHAIN LENGTH) The

distance from the first pin

counted to the last pin counted

in a span while the chains are

lifting a small load.

3

2

4

1

Summary of Contents for C15 D

Page 2: ......

Page 6: ...iv...

Page 16: ...1 4 Seat Belts Seat Belts ALWAYS BUCKLE UP Seat belts can reduce injuries...

Page 30: ......

Page 88: ...5 8...

Page 107: ...PM Report Form 7 13 Section 7 Planned Maintenance and Lubrication...

Page 124: ...7 30...

Page 142: ......

Page 143: ......