11

CONNECTING THE AIR SUPPLY

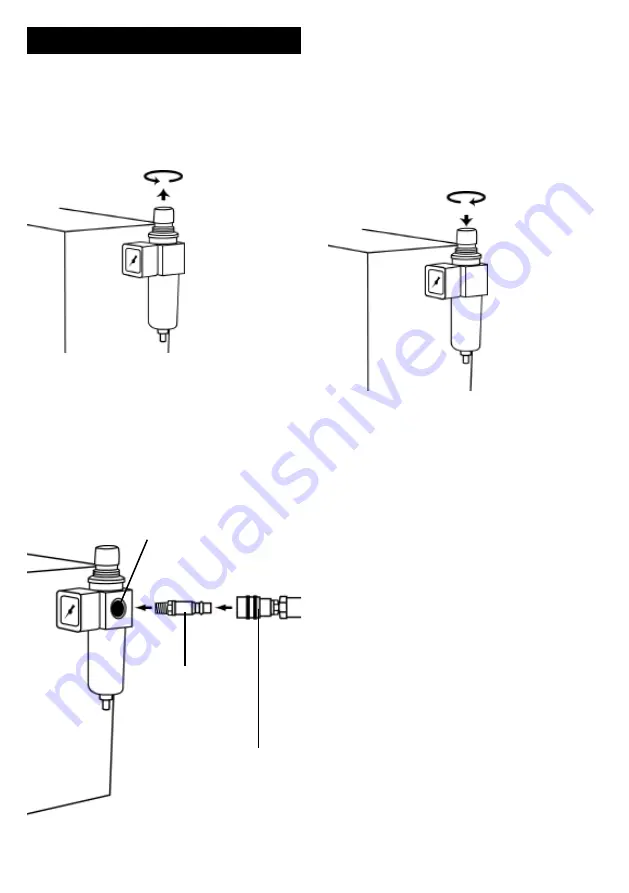

1. Before attaching the air supply to the

plasma cutter, pull out the air pressure

regulator knob and turn it fully counter-

clockwise. This will set the regulator to its

lowest pressure. (see Figure 2)

2. Feed the 1/4 inch male air coupler

threads into the plasma cutter’s air inlet.

Firmly tighten in place with wrench.

Note:

The use of a sealant tape is recom-

mended on the threads of the air coupler to

prevent air leakage.

3. Attach air hose (with quick connect cou-

pler) to 1/4 inch male air coupler. Make

sure air hose is fully seated on coupler

before letting go. (See Figure 3)

4. Turn on the air supply. Make sure that

the air supply pressure is at least 90psi.

(90 -120 psi is ideal)

5. Pull out the air pressure regulator knob

and set a pressure of 65 psi by turning

the knob clockwise.

6. When the pressure on the air regulator

gauge is set to 65 psi, lock the knob in

position by firmly pushing down on it.

(See Figure 4)

CONNECTING THE GROUND CLAMP

TO THE WORKPIECE

1. Remove any dirt, grease, scale, rust,

paint, etc. from the area of the workpiece

where the ground clamp is to be connect-

ed.

2. The ground clamp should be connected

to the workpiece as close to the area

being cut as possible. Make sure when

connecting the ground clamp that neither

the ground clamp or the ground cable will

intersect the intended cut line.

3. Fasten the ground clamp to the work-

piece. Make certain the ground clamp is

securely fastened to the workpiece so

that it will not be likely to come loose dur-

ing the plasma cutting operation.

POWERING UP THE UNIT

1. Plug power cord into properly grounded

120VAC, 60Hz, single phase power

source.

2. Switch the unit ON, using the main power

switch on the rear panel of the plasma

cutter. A hissing of air will be apparent for

a short period as the system is charged

and the water trap drain valve closes.

3. Make sure that the Power Indicator Lamp

on the front panel of the machine is on,

Figure 2

Lowering Regulator

Pressure

Air Inlet

1/4 inch Male

Fitting Air Coupler

Air Hose with

Quick Connect

Figure 3.

Connecting the Air Supply

OPERATION

Figure 4

Adjusting Regulator

Pressure

Summary of Contents for 052249011064

Page 17: ...17 TROUBLESHOOTING...

Page 18: ...18 18 PLASMA CUTTER MODEL WE6493A WIRING DIAGRAM...

Page 19: ...19 19 PLASMA CUTTER MODEL WE6493A PARTS LIST...

Page 20: ...20 PLASMA CUTTER MODEL WE6493A PARTS DIAGRAM...

Page 21: ...21 PLASMA CUTTER MODEL WE6493A TORCH PARTS LIST...

Page 22: ...NOTES...

Page 23: ...NOTES...

Page 24: ...120V PLASMA CUTTER OPERATING MANUAL Model WE6493A WE6493A M001 1204...